For this episode of the Dusty Jobs Podcast, Donovan meets with Josh Pawley from Vectis Automation at Fabtech. Josh talks about what the difference is between traditional robots and cobots. He also talks about why a company would want to use a cobot and how it can make a more efficient and cleaner work environment.

Narrator: Welcome to the Dusty Jobs podcast from Imperial Systems. Industry knowledge to make your job easier and safer.

Donovan: Hello and welcome to another episode of the Dusty Jobs Podcast. We’re still here at Fabtech and we’re joining us today is Josh Pawley with Vectis Automation.

Josh: Yes sir.

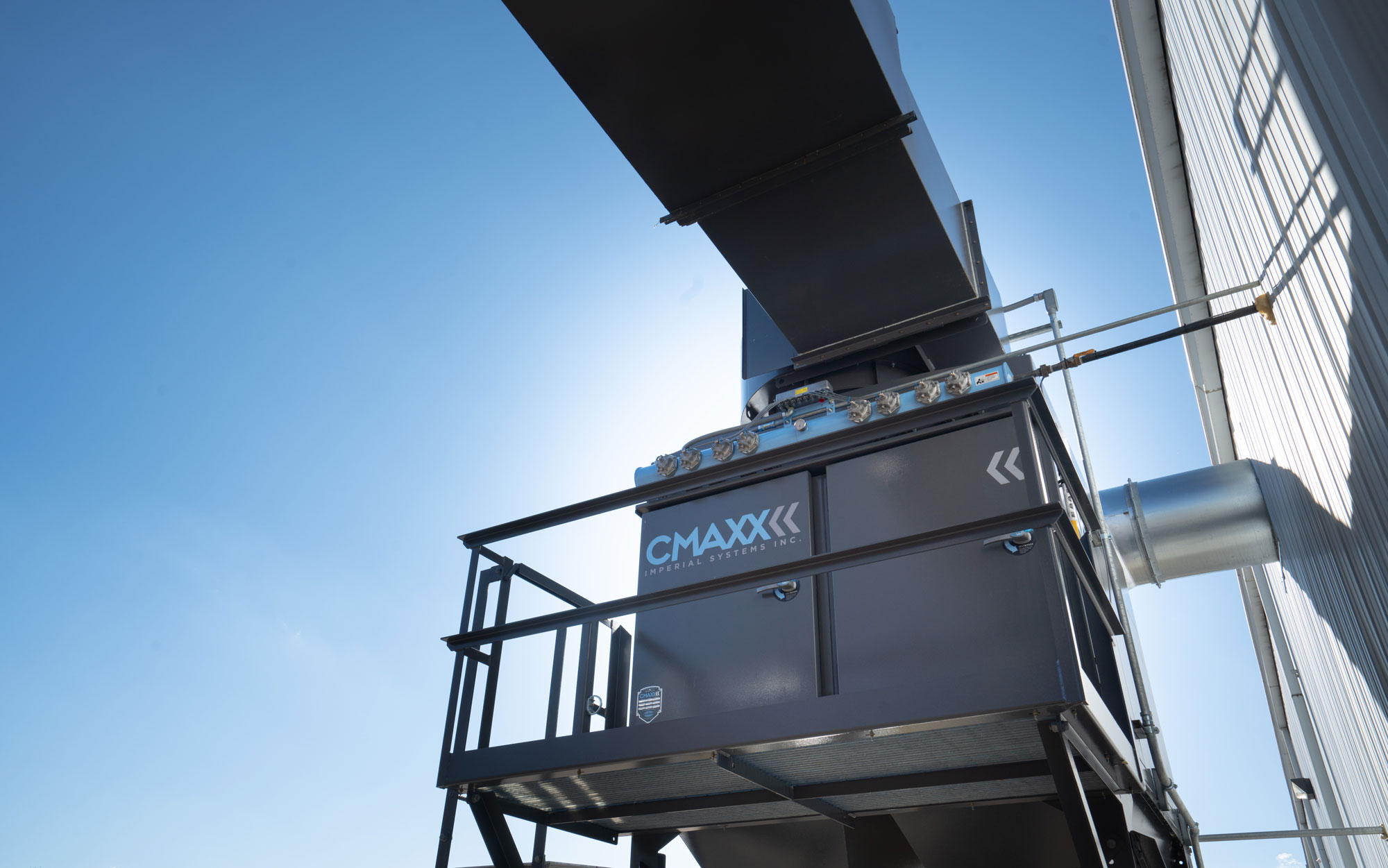

Donovan: They’re one of our neighbors here at Fabtech so they’re in the booth next door and they were kind enough to lend us one of their cobots in our booth. It has been just really cool to see it all week just over there moving around and and working underneath our Air-Port Hood but we want to learn more about you guys. Josh you’re one of the founders, is that right, of the company? So how did you get into this world? This is I mean cobots, robots, everything’s coming down the line. How did you get into the robotics industry to start out?

Josh: Yeah so my career actually started in robotic welding 12 years ago. I was a mechanical engineering student at Colorado State University. Sophomore, walked into a career fair and found this company Wolf Robotics, talked to them, was able to land an internship there and that’s kind of where it all started. So that was in 2011. Did assembly, kind of building the systems first, then applications engineering, project management, was a regional sales manager helping customers solve their problems at that company and then in 2019 some of my colleagues and I we got together and founded Vectis. So the whole idea behind Vectis is making automation easier to use, more accessible for a broader range of manufacturers right?

Donovan: Okay.

Josh: Traditional automation solutions have a lot of hurdles to them right? You know there’s cost, footprint, flexibility, programming time, training time, fixed time and cost. So our whole goal is how can you democratize that right? How can you make it much easier to bring automation to folks where it wasn’t quite accessible before?

Donovan: Well yeah I know we’re seeing that a lot here at the show in general is that you know one of the jokes is that robots don’t get sick, they don’t call off, they tend to keep working. But you guys aren’t a robot, you guys are a cobot right? So maybe there’s some people out there that don’t know what that is. Can you break down with the difference between a cobot and a robot is?

Josh: Absolutely. So a cobot is a robot, it’s just a squishing together of collaborative and robot right?

Donovan: Okay.

Josh: And it’s collaborative in the sense they’re at their six axis arm just like robots have been for decades.

Donovan: Gotcha.

Josh: There are six axis arm but it’s unique in the fact that humans can work along side it. And that’s empowered by the fact that there’s force, torque and power sensing on every axis. So if it runs into you it’ll stop before it hurts you right? And so now you can do away with the caging, you can do away with the light curtains, the door interlocks, all that stuff right? That makes traditional automation a bit more monumental right? And now it’s becoming more, we even call them tools right? The whole idea is how can it be easy to use flexible tools for the welder/fabricator.

Donovan: Well and I can say from sitting here watching your guys piece of equipment all week in comparison to some of the other robots at the show that yours seems to have a real, it’s a real smooth motion. It moves real, real carefully and smooth.

Josh: Approachably is what we like to say.

Donovan: Yeah there you go. That’s a great word.

Josh: It’s approachable right? In the fab shop you’re not scared of it right? When you look at traditional robots that are very heavy and move very fast, they were born for automotive. They were born for doing millions of parts and cars.

Donovan: Yeah and that’s it you see those and they’re like –

Josh: So a third of a second of a cycle time matters. So you’re moving quick. You’re moving fast. The whole thing’s cordoned off because automotive’s aligned right? So yeah absolutely there’s no operators involved right? Whereas on the flip side we’re trying to fill that gap for customers doing 20 parts, 50 parts, 500 parts right? Where I want a more approachable tool versus a high production line robot right?

Donovan: Yeah so if I’m sitting here what would be, tell me some fields, some jobs that your unit is just ideal for like what would that be? Because it’s not, like we’re talking, it’s not automation, it’s not slamming out a hundred parts in 20 minutes or whatever. It’s for what? What would be ideal for you guys?

Josh: It’s a great question, it’s a tough one to answer because we find more and more applications every day and the answer is it’s a very broad range right? You know we’ve got anything from job shops doing batches of 20s, 50s, 500, 5000 right? Those medium volume quantities right? To OEM manufacturers making construction equipment, making mining equipment, making agricultural equipment, making widgets right? We just spoke to someone that’s making garden tools right? Those have to get welded right? We spoke to someone making drinking fountains. Those have to get welded. There’s so many things as y’all know it welded in everyday life that if there’s some level of repetitiveness to them the whole idea is how can we offload the boring arc on time to the cobot leaving the skilled human welders to really focus on the welds that require skill right? And that are tougher for any type of automation to do.

Donovan: Yeah. And probably also helping to eliminate some of the health risks that come along with some of this type of welding. You know some welding is not as bad as others and I’m sure having a cobot in that space to handle something that we don’t want in our own breathing zone is ideal.

Josh: Well and especially when you pair it with like the Air-Port right? Because now you’ve got the ability to one, get the human operator, human welder farther away from the fume exposure right? Then we’ve got the ability to capture that as well right? So you’re absolutely creating a healthier safer shop you know fewer black boogers coming out of the nose at the end of the day right? Which benefits everybody right? And we you know we talk a lot about the skilled labor shortage, the skilled welder shortage. Well it’s not – I don’t know if it’s a job I would pick right away right? Because it is dirty right? So what can we do together to create a safer, healthier work environment as well right? Let’s get those fumes out of there. Let’s get the operator farther away from the fumes. Let’s get the operator using a tool to accomplish those boring tasks.

Donovan: Now you keep calling it a tool and to me personally if someone put that in front of me and said you need to run this it seems a little intimidating to me. But I mean that’s what you guys do you build the software I mean how hard is it for a guy like me who doesn’t have a lot of experience or maybe someone out there who’s thinking about this how hard is it to really learn how to use one of these things?

Josh: Most customers are welding within the first day.

Donovan: Really?

Josh: And even and particularly the ones that have no prior experience with robotics or automation or whatnot. That’s really what we’ve done with the product is lower that technological threshold to be able to start using it right? I kind of make the comparison to you know let’s say you’ve got you got to put nails and studs right or build a roof right? You’ve got two tools at your disposal you got a hammer and you got a root and a nailer right? Both are valuable right? Let’s now make that analogy a you know manual welder and a cobot tool right? There are going to be nails that make sense to be driven with the hammer right? But for one you know when you’re doing the sheeting on the top of the roof why not grab the nailer right? There’s a little you know to a nailer it’s a little intimidating yeah hey with some quick instruction you can get it going pretty quick right? So that’s the whole idea is the boring monotonous repetitive tasks what can you offload to those cobots?

Donovan: But I don’t have to be a computer programmer to run this thing right?

Josh: Correct so yeah so most of our customers it’s a welder, a fabricator, a grinder that that’s programming the cobot right? That was exactly the intent that we made the system for was for folks that are not programmers not CNC operators not engineers to be able to pick it up and use it very quickly.

Donovan: From talking to you before that’s really what you guys your specialty is just your software that allows that to be easy.

Josh: Yeah it’s a software definitely. Tt’s the integration options to accomplish a wide range of applications and then see application expertise you know. We’ve got over two hundred we’ve been doing this together for over 200 years combined experience. Being able to help especially new customers navigate how do I be successful with automation right? That’s the other thing that we really help bring to the table.

Donovan: Yeah so I don’t I don’t have to be an expert in automation because you guys will be the experts and just let me know.

Josh: And our whole mantra is we want to teach our customers how to fish not give them a fish right? Because if you’re taught how to fish you can eat for a lifetime right? So and I think it’s really cool to see as well with you know again the skilled labor shortage technology like this especially when it’s in a cleaner environment with an Air-Port or another Imperial Systems product we’re bringing more folks in the industry because it’s made it’s being made to be more interesting. I get to use technology. I get to work in a cleaner healthier environment right? So I think I think it’s one of the ways that we can one, solve the crisis by increasing productivity but also by bringing more folks into the workforce.

Donovan: Yeah and we found that too it’s a lot of people used to just assume that if you’re gonna be a welder you’re gonna be down down in the dirt in the muck and as things change and people progress shops are getting cleaner and cleaner and cleaner and and things like using cobots and having clean air is I think that’s just where it’s going.

Josh: Yeah I believe so too.We see customers using it as a recruiting tool like, “Hey come work for us because our shop is cleaner. We have cool technology that you can use.” It’s a powerful tool to the next generation.

Donovan: I don’t think it’s going away.

Josh: I agree.

Donovan: I think it’s important for those shops that are out there that are weld shops to figure out who they not just want to buy something from but who they want to partner with in this in this side and that sounds like what you guys are all about it’s not just selling someone a piece of equipment but partnering with them –

Josh: Absolutely

Donovan: – and finding the right solution for them.

Josh: Absolutely we only win when our customers win, right? We’re privately held. We’re not beholden to anybody but our customers and our team members right? So it’s even one of the reasons why we’re able to offer our 30-day money-back guarantee which is nuts in capital equipment right but it’s because we’re doing our due diligence to make sure we’re doing right for our customers the whole way through right.

Donovan: That’s phenomenal. So where are you guys based out of?

Josh: We’re in Colorado, Loveland, about an hour north of Denver.

Donovan: Okay and if anybody out there is interested in seeing more about your equipment or getting more information how would they do that?

Josh: Heck yeah. Great way is our website www.vectisautomation.com. V-E-C-T-I-S. We’re also really active on LinkedIn. There’s a lot of good content. You can see a lot of customer, implementations get some ideas flowing. So LinkedIn you can search for Vectis Automation there and our YouTube channel as well Vectis Automation YouTube channel just see get some ideas flowing on how it might be relevant in your shop.

Donovan: You guys you’re just like us American-made American owned company right?

Josh: Amen. Do it right by customers. Absolutely. I love it.

Donovan: I know it’s a busy show. We all have things going on and I really appreciate you stopping by.

Josh: Thank you. It’s been great to partner in your booth and I love this demo and being able to show – I love the fog machine right it shows exactly how that system is gonna help keep a shop cleaner so we appreciate the partnership.

Donovan: Well it’s great so same with us if you guys are interested in learning more about Imperial you can find us on YouTube, our website, LinkedIn, Facebook, most social media platforms were on there but thanks for listening and until next time stay healthy and stay safe.

Narrator: Thanks for listening to the Dusty Jobs podcast. Breathe better, work safer.