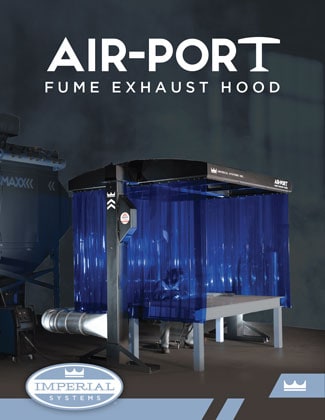

Air-Port Fume Exhaust Hood

Not much has changed in the design of the welding hood, at least until now. The Air-Port Fume Exhaust Hood eliminates the weaknesses of standard fume extraction hoods. It also brings its own unique set of patent pending benefits for weld fume seen nowhere else. For standard and robotic welding, the Air-Port offers the first true new innovations in welding hood design.

The Air-Port Fume Exhaust Hood is compatible with a variety of robotic welding system manufacturers, including but not limited to

| • Kawasaki Robotics | • Motoman Robotics |

| • Yaskawa | • Fanuc |

| • Kuka Robotics | • ABB Robotic |

| • Mitsubishi Robotics |

Are you a welding robot manufacturer? We may be a great OEM partner for you.

Other welding hoods stand on four or more legs that bend or break. You can settle for poorly made or makeshift products. You can order fume exhaust hoods, which can have a ten week lead time and will still require you to cut and modify them onsite. Many take hours and several people to install. Your new option is the Air-Port Fume Exhaust Hood.

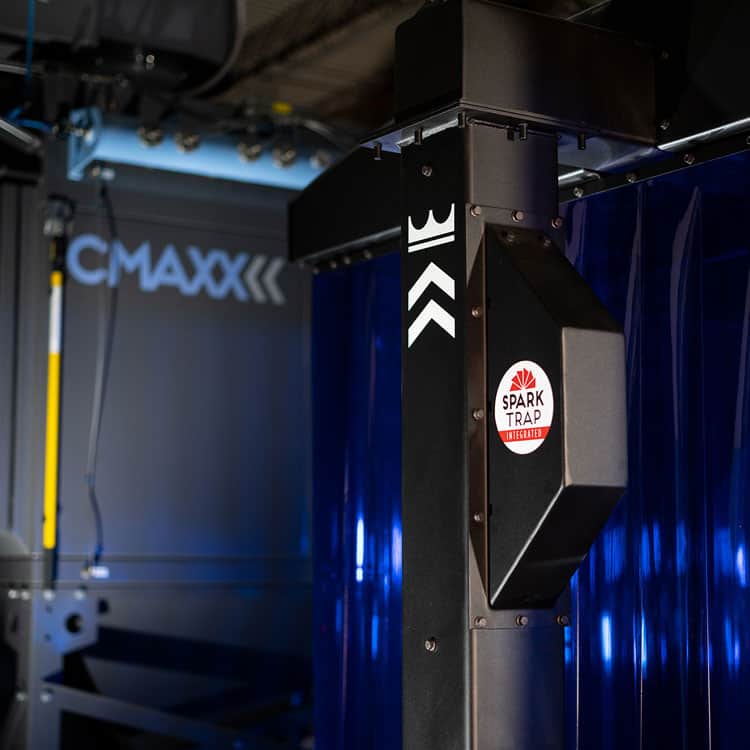

The Air-Port is a ducted fume hood that arrives ready to use. The ductwork is pre-installed into its two compact, low footprint legs. Optional built-in Spark Traps give you another industry first in welding hood safety. Adjustable dampers built into the extraction hood make it easy to balance the air flow for your needs. With the arched hood shape, the Air-Port Fume Exhaust Hood captures more smoke and fumes.

Traditionally, a spark trap is a supplemental piece of equipment added to the duct before a dust collector. Our Spark Trap is integrated into the duct leg of the Air-Port Fume Exhaust Hood. If sparks in the airstream do enter the leg of the ducted fume hood, they are knocked out in the integrated Spark Trap before reaching the collector.

NFPA standards strongly recommend spark traps as part of a complete fire prevention system. Keeping sparks away from the dust in your collector is the first step to safely handling combustible dust. An integrated Spark Trap in your fume extraction system will certainly help you do that.

WITHOUT AN INTEGRATED SPARK TRAP

WITH AN INTEGRATED SPARK TRAP

AIR-PORT FUME EXHAUST HOOD FEATURES

- Two-person install in under an hour

- Pre-installed ductwork in legs and cross beams

- Optional integrated Spark Trap available

- Two-legged design means a smaller footprint

- Arched fume extraction hood design contains smoke and fumes

- Dampers for easy air flow adjustment

- Designed for manual and robotic welding

OPTIONS

CRANE SLOT

A brushed opening in the extraction hood allows cranes to easily enter and place heavy equipment, like robotic spot welders, beneath the hood.

WELD CURTAIN

The Air-Port can include a blue welding strip curtain. It keeps both your welders and anyone walking through your facility safe from dangerous weld fume and smoke.

INTERNAL LIGHTING

Optional lighting in the hood provided increased visibility for welders and those servicing robotic welding systems.

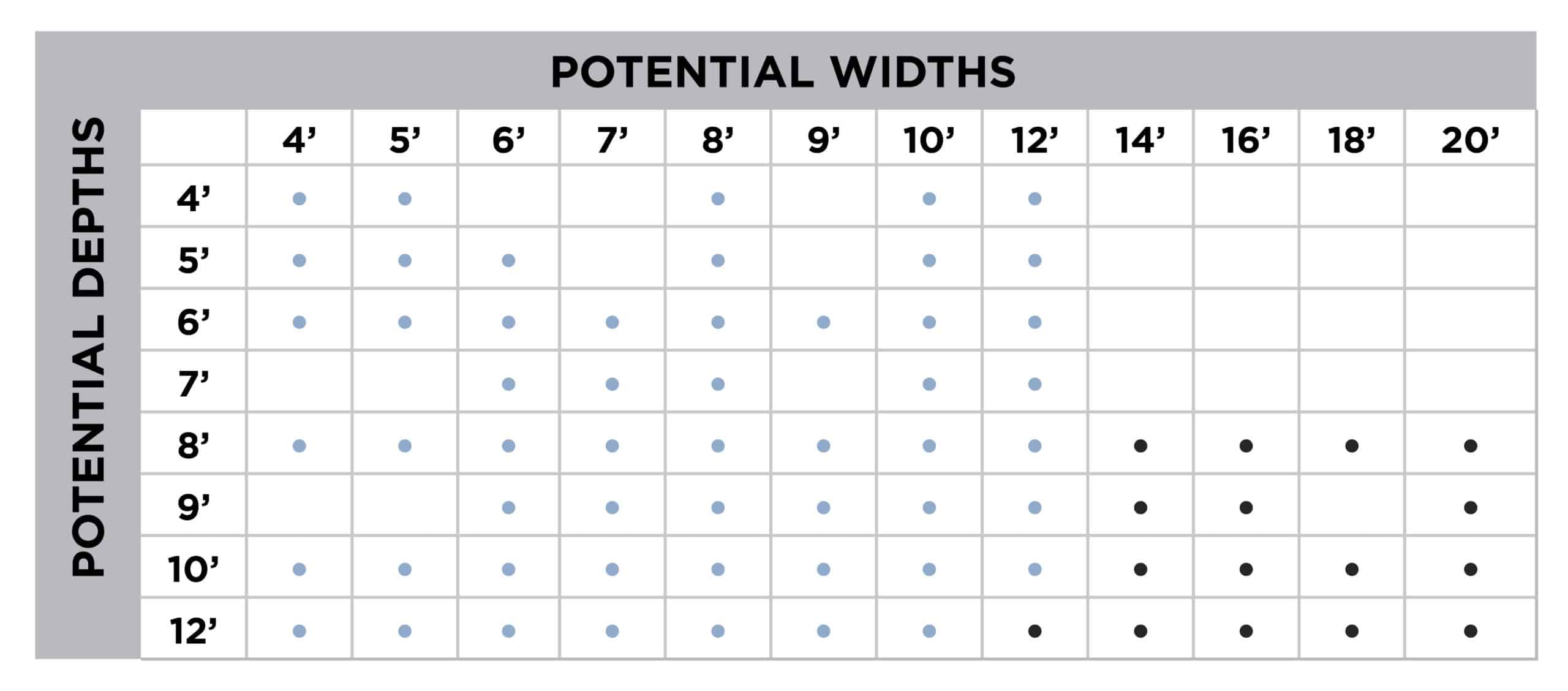

AVAILABLE IN A VARIETY OF SIZES

The Air-Port Fume Exhaust Hood is available in a variety of sizes. They begin at 4’ x 4’ and range all the way up to 12’ x 20’. Standard heights include 8, 9, and 10 feet. Hoods can also be hung with chains from the ceiling.

Taller hoods may be available. Note that ducted fume hoods marked with a darker dot may require ducting to both support legs.

Why should I choose the Air-Port Fume Exhaust Hood when there are cheaper alternatives on the market?

Alternative #1 – Other Fume Hoods

The Air-Port Fume Exhaust Hood was designed with the customer and mind, and offers benefits not available with other fume extraction hoods. While some of these welding fume hoods stand on four legs and also require ducting, the Air-Port is a ducted fume hood that incorporates the ducting into one or both of its two legs. This saves floor spaces, and makes it easier for a welder to navigate beneath the hood.

Alternative #2 – Weld Guns

A less common solution to weld fume is using weld guns. While these guns collect weld fume at the source, they may not reliably capture all the fume. Additionally, these guns are notoriously heavy and cumbersome for welders that may be using them all day long. This method may be best suited for robotic welding systems, but still may require some form of backup to capture all of the weld fume.

Alternative #3 – Fume Arms

Fume arms are a common solution for welding fume extraction systems, but aren’t always the most practical for those expected to use them. Fume arms can be dangerous for welders, especially those producing stainless steel welding fumes, as their use depends on the welder taking the time to move the arm to where they’re welding. For those welding all day, this can become an annoyance, and many welders can not be bothered.

A welding booth can be the perfect solution to this issue. As long as the hood is sized properly, welders should be able to do their job, moving freely beneath it while the hood removes dangerous weld fume from their breathing zone.

Alternative #2 – Weld Guns

A less common solution to weld fume is using weld guns. While these guns collect weld fume at the source, they may not reliably capture all the fume. Additionally, these guns are notoriously heavy and cumbersome for welders that may be using them all day long. This method may be best suited for robotic welding systems, but still may require some form of backup to capture all of the weld fume.

Alternative #4 – Downdraft Tables

Downdraft tables can be used to remove weld fume from a welders breathing area, but may come with restrictions. Downdraft tables may work best in ares where there are multiple types of fabrication occurring, such as welding and grinding. These table create a size restriction, as the work is limited to the space available on the table. Additionally, downdraft tables are not a viable solution for robotic welding systems.

Why do welding fumes need to be collected?

Welding various types of metals can produce different weld fumes, and some are more dangerous than others. Stainless steel welding fumes can be especially dangerous to a welder’s health. It is important to collect this fume with a welding fume hood to remove it from the welder’s breathing zone.

Welding stainless steel produces hexavalent chromium, a known carcinogen. These stainless steel welding fumes, if left unchecked and uncollected for a welder to breathe in, may cause lung cancer. This means that getting that welding fume out of a welder’s face as quickly as possibly is critical.

A ducted fume hood connected to a fume extraction system is the perfect solution to ensure the health of welders. The Air-Port Fume Exhaust Hood pulls the fume up and away from the welders breathing zone. It enters the hood’s build in ductwork and exits to a dust and fume collector such as the Shadow Compact Fume Extractor or CMAXX Dust & Fume Collector. These collectors filter out the dangerous particulate before returning air to the facility.

The Air-Port may also include weld curtain to ensure that the dangerous weld fume stays within the confines of the weld booth. The fume should be quickly collected by the extraction hood and not escape and linger in the shop.

The Air-Port Fume Exhaust Hood is easily paired with the Shadow Compact Fume Extractor. If the Air-Port is being used to collect non-combustible particulate, the Shadow may be the best option to contain and dispose of the dust.

The Shadow’s small footprint makes it easy to situate next to an Air-Port Fume Exhaust Hood for easy ducting. The simple install of both the Air-Port and the Shadow make it a quick solution to collecting weld fume.

If your application is in need of greater airflow, consider the CMAXX Dust & Fume Collector. This option should also be considered for particulate that may be combustible.

CMAXX is the most heavy-duty collector on the market and was built to withstand a combustible dust explosion. It easily connects to the Air-Port Fume Exhaust Hood. With a redundant Safety Pentagon design, it’s sure to keep your facility and employees safe.

Don’t have an Imperial Systems collector? No problem!

The Air-Port Fume Exhaust Hood easily pairs with many different brands of dust collectors. This includes but not limited to Donaldson Torit, Camfil Farr, Robovent, Lincoln Electric, and many more.

SERVICEMAXX SUPPORT

All our dust collectors are made in the USA. You’ll always have the full support of our dust and fume collection experts here in our Pennsylvania facility. Each Air-Port Fume Exhaust Hood is designed by our team of engineers.

Our professional ServiceMAXX teams can travel almost anywhere. They’ll make sure your Air-Port is working as it should be. No other dust collector company offers better, more personal support.

Frequently Asked Questions

Can the Air-Port be daisy chained together?

Each Air-Port has its own outlet. Each outlet can be ducted to a common trunk line that runs to your dust collector.

Has the Spark Trap been tested?

The Spark Trap has been tested in an extreme spark environment. We connected a GreCon spark detection monitor to the duct leading to a collector with and without the Spark Trap. The Spark Trap was proven to reduce the volume of sparks reaching the detector by over 99%.

Can you balance the air in the hood?

Each Air-Port Fume Exhaust Hood has multiple tool-free slide gates in the tube. They can be adjusted to optimize airflow for your specific application.

Can I add lighting?

Yes lights are available as an option. LIghting must be wired on site.

Is the weld curtain included?

Blue welding strip curtain is available as an option. You are able to select per side based on 2, 4, and 6 foot lengths.

Is this hood only for robots?

No, the Air-Port Fume Exhaust Hood can be used in almost any application that you are trying to capture smoke or fume particulate over a cell or work station.

What are the CFM requirements?

The CFM requirements have a wide range and is based on the size and height of the hood.

Does this have to be bolted down?

Yes, the Air-Port Fume Exhaust Hood must be securely attached to the floor.