Dust Test

Combustible dust is a serious hazard in many industries, including manufacturing, food processing, and woodworking. The accumulation of fine particulate in the air can create an explosive environment, putting employees at risk. To prevent these incidents, it’s crucial to identify the risk of combustible dust in your workplace and take appropriate measures to mitigate it. Combustible dust testing can help you determine the risk level in your facility and develop a comprehensive plan to ensure the safety of your employees and property. We partner with an experienced team of experts at a combustible dust testing laboratory, who will provide everything you need to know about your dust.

Combustible dust is a serious hazard in many industries, including manufacturing, food processing, and woodworking. The accumulation of fine particulate in the air can create an explosive environment, putting employees at risk. To prevent these incidents, it’s crucial to identify the risk of combustible dust in your workplace and take appropriate measures to mitigate it. Combustible dust testing can help you determine the risk level in your facility and develop a comprehensive plan to ensure the safety of your employees and property. We partner with an experienced team of experts at a combustible dust testing laboratory, who will provide everything you need to know about your dust.

HOW DOES A DUST TEST WORK?

Combustible dust testing involves evaluating the explosibility and flammability of dust particles that may accumulate in a manufacturing or processing environment. Typically, the testing is performed using specialized equipment that simulates conditions similar to those in the facility. This allows for accurate determination of the risk of dust explosions and enables facility managers to take the necessary precautions to prevent such incidents.

So, when you send your dust sample off to a combustible dust testing lab, what do they do with it?

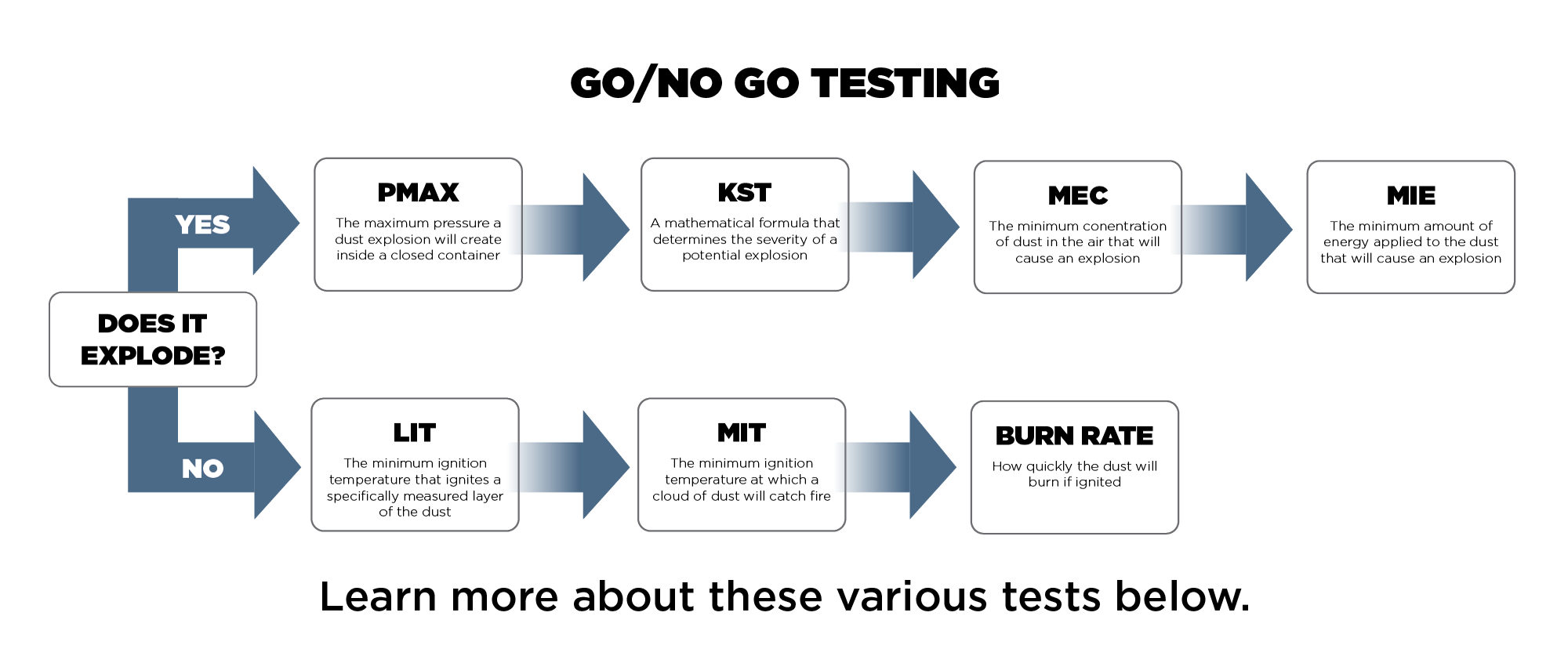

The first test is usually the “go/no go” test. This test determines the explosiveness of the dust. A “go” result means that under basic testing, the dust will explode. A “no-go” result indicates a non-explosive, but possibly still flammable, dust.

PMAX (Maximum Pressure Test)

A PMAX test, or maximum pressure test, is designed to determine the maximum pressure that can develop in a confined container during a deflagration event. During the test, a dust sample is placed in a sealed test chamber and then ignited. The pressure wave created by the resulting explosion is measured and recorded, which can be used to calculate the maximum pressure that could be generated in an actual dust explosion under similar conditions. This information is then used to design and implement effective dust collection systems and other safety measures.

KST (Explosion Severity Test)

The combustible dust explosion severity test is a combustible dust laboratory test used to assess the destructive potential of a dust explosion. The test involves exposing a dust cloud to an ignition source and measuring the resulting pressure increase and blast wave. This information can be used to determine the maximum explosion pressure and the impulse generated by the explosion, which are key parameters used to assess the severity of a dust explosion. The results of the explosion severity test can be used to design explosion protection and dust collection systems, and to assess the explosion hazard of a particular dust.

MEC (Minimum Explosible Concentration)

The minimum explosible concentration (MEC) test is a combustible dust laboratory test used to determine the lowest concentration of a combustible dust in air that can ignite and sustain a dust explosion. The test involves creating a dust cloud of varying concentrations in a controlled environment and exposing it to an ignition source until ignition and sustained combustion occur. The lowest concentration at which ignition and sustained combustion occur is recorded as the MEC. This information is useful in assessing the potential for dust explosions and in designing explosion protection and dust collection systems.

MIE (Minimum Ignition Energy)

The minimum ignition energy (MIE) test is a combustible dust laboratory test used to determine the electrical spark energy required to ignite a dust cloud. The test involves creating a dust cloud in a controlled environment and exposing it to electrical sparks of varying energy levels until ignition occurs. The lowest energy level at which ignition occurs is recorded as the MIE. This information is useful in assessing the potential for dust explosions and in designing explosion protection and dust collection systems.

LIT (Minimum Ignition Temperature)

This minimum ignition temperature dust layer test is a combustible dust laboratory test used to determine the temperature at which a dust layer ignites. This test is used to assess the ignition properties of dust layers in real-world conditions, as opposed to single particles or clouds. The test involves spreading a layer of dust on a surface and then exposing the dust layer to a heat source until ignition occurs. The temperature at which ignition occurs is recorded as the MIT. The results of the MIT dust layer test can be used to assess the ignition properties of dust layers in real-world environments and to inform the design of explosion protection and dust collection systems.

MIT (Minimum Ignition Temperature)

This minimum ignition temperature dust cloud test is a combustible dust laboratory test used to determine the temperature at which a dust cloud ignites. The test involves creating a dust cloud in a controlled environment and exposing it to a heat source until ignition occurs. The temperature at which ignition occurs is recorded as the MIT. This information is useful in assessing the potential for dust explosions and in designing explosion protection and dust collection systems. The MIT dust cloud test provides valuable information about a dust’s ignition characteristics and can be used in conjunction with other tests, such as minimum ignition energy tests, to provide a comprehensive evaluation of a dust’s explosion hazard.

Burn Rate

A burn rate test is a laboratory test used to determine the combustibility of a dust by measuring the rate at which it burns and the length of the flame it produces when ignited. The test involves setting up a controlled fire scenario in a combustible dust testing laboratory, in which a small amount of the dust is introduced into a controlled air flow and then ignited. The rate at which the dust burns and the length of the flame it produces are then measured and used to determine the severity of the dust’s explosion hazard. This information can be used to inform the design of dust collection and explosion protection systems.

The industry uses Kst as a standard measurement of dust’s explosiveness. A dust with Kst below 100 is considered a minor explosion. Below 200, the explosion is considered strong, and above 200, the explosion will be very strong.

This information can help prevent a lot of problems. LIT, for example, tells you how hot a surface (like an overheating bearing) can get before it will ignite a layer of dust. MIE tells you how your dust will respond to a spark or other ignition source. At a very high MIE (this is a measurement of temperature), the dust won’t ignite without a lot of energy input. At a very low MIE, dust will ignite from even a tiny spark or static charge.

WHAT COMES AFTER THE DUST TEST?

After your dust test shows that your dust is combustible, you will need to complete a dust hazard analysis (DHA). NFPA 652 does not specify who should do this, as long as they are “an expert” and their knowledge is satisfactory to the facility owners. Safety, maintenance, and shop floor managers can all be involved.

WE'RE HERE TO HELP

If you have concerns that your dust collection system may not meet safety standards, contact us and a service technician can help evaluate your system performance.

HOW TO SUBMIT DUST FOR AN NFPA 652 DUST TEST

Take samples from the dirty air side of the dust collector for best results. For an accurate measurement, empty the collection drum and then collect a recently pulsed sample. In a full drum, large particles may settle and leave smaller ones at the top.

If you don’t have a dust collector, you can collect dust from surfaces or machines in your shop. Just make sure the sample represents your general dust. Don’t collect damp dust or large chunks.

Ship your sample in a well-sealed container. Include an MSDS sheet and follow all MSDS transport precautions for that material.

Frequently Asked Questions

I already have a dust collector. Do I need to get my dust tested?

NFPA 652 is retroactive. It applies to all facilities, old and new, with combustible dust.

I have multiple types of dust. Do they all need tested?

All dust must be tested unless there’s documentation of testing on identical dust.

What if I don't get my dust tested?

NFPA standards are not laws, but are followed by insurers, building codes, and fire codes.

Can Imperial Systems test my dust?

While we don’t test dust in our facility, we can send your sample to right place!

What does the combustible dust test tell you?

We can help you understand what all the number mean. Click here to read more.