REPLACEMENT DUST COLLECTOR CARTRIDGE FILTERS

Support You Can Rely On

Our filter experts can provide technical support and troubleshooting as well as custom solutions for troublesome applications.

American Made & Sourced Parts

By relying on American made and sourced materials and keeping thousands of components in stock, we are able to offer customers faster and more reliable lead times.

Hand Crafted Attention to Detail

Our manufacturing specializes in cartridges filters, and cartridge filters alone. Our filters are carefully hand assembled and built to meet or exceed OEM expectations.

Dust Collector Cartridge Filters for Your Brand

Your dust collection system may have horizontal filters, like a Donaldson Torit collector, or vertical filters, like a Camfil Farr collector. Either way, we can provide high-efficiency replacement cartridge filter for your system. We offer competitive pricing on a better quality filter. This is why so many customers that try someone else come back to Imperial Filtration.

We manufacture replacement cartridge filters for industrial air filtration systems, including (but not limited to):

Camfil Farr

Lincoln Electric

Airflow Systems

Sly

Plymovent

Micro Air

Messer

Flex-Kleen

Steelcraft

Trion

ACT

AAF

MAC

Many others

P190817 – OEM Replacement

Donaldson Torit DFT Replacement

- Outer Diameter: 13.84″

- Height: 26″

- End Cap Design: Open

- Media: Nanofiber

- Filter Media Area: 254 ft2

P191920 – OEM Replacement

Donaldson Torit DFO Replacement

- Outer Diameter: 11.40″ x 14.40″

- Height: 26″

- End Cap Design: Open

- Media: Fire Retardant Nanofiber

- Filter Media Area: 189 ft2

325325-001 – OEM Replacement

Camfil Farr Gold Series Replacement

- Outer Diameter: 15.125″

- Height: 39″

- End Cap Design: Closed

- Media: Nanofiber

- Filter Media Area: 325 ft2

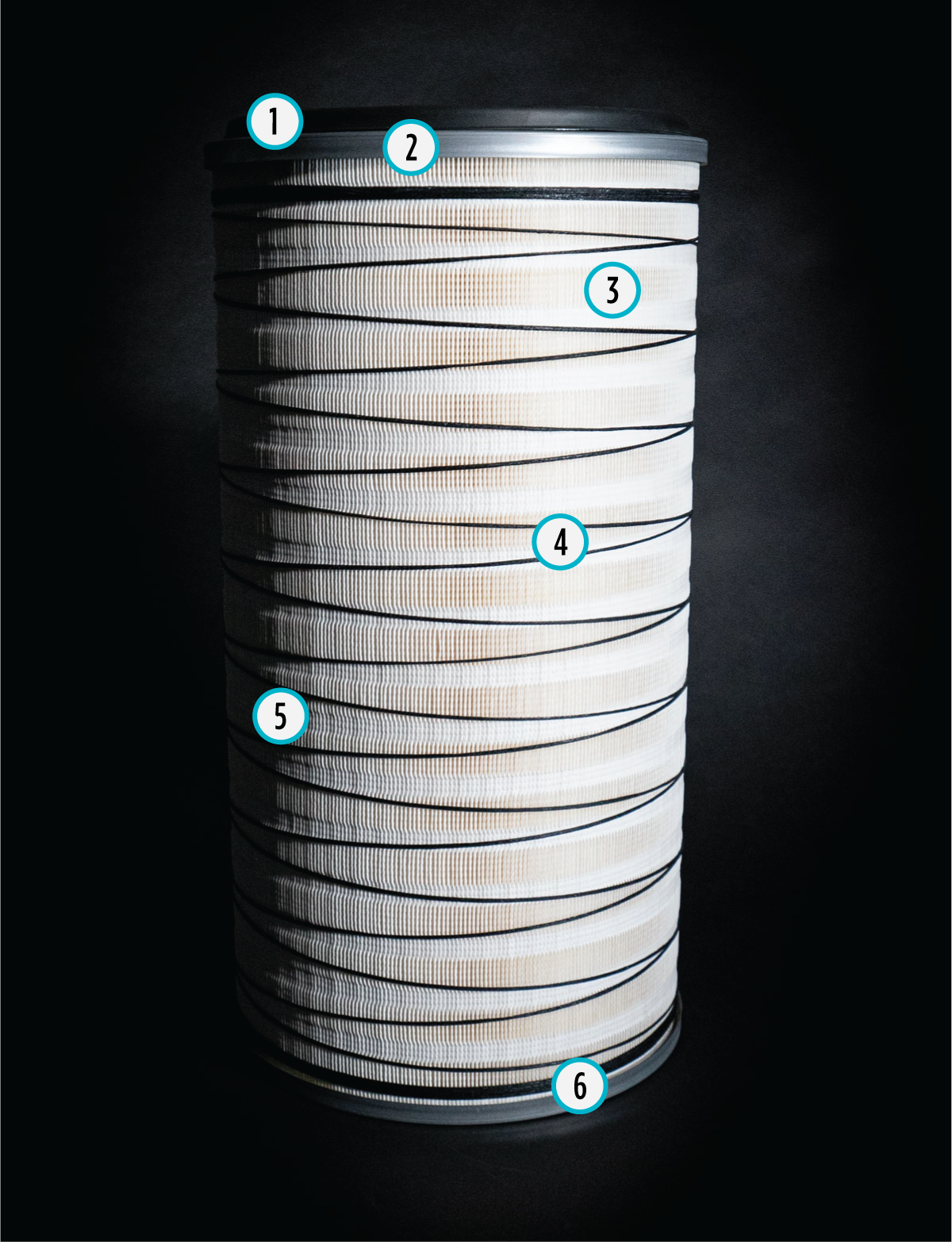

THE BEST CONSTRUCTION ON THE MARKET

Hover to learn more.

Durable gasket material designed to seal in any application

Top adhesive technology for optimal filter assembly

Most advanced filter medias designed for efficiency and durability

Designed with a double helix cording for increased strength

Hand crafted with extreme attention to detail

Heavy duty American sourced steel and components components

The Imperial Filtration Story

Our goal has always been not just to settle for what works, but to strive for constant improvement and innovation. Imperial Filtration was born out of the necessity for a better quality filter. For years, Imperial Systems has put time and care into making the best dust and fume collectors on earth, and now that same quality is seen in Imperial Filtration’s cartridge filters.

While other companies are trying to juggle manufacturing many different types of filters, Imperial Filtration is specializing in creating the best possible cartridge filter for almost all industrial brands of dust collectors. Experience unmatched customer service, application expertise, and the best construction on the market with Imperial Filtration.

Application Expertise

Imperial Filtration’s focus on cartridge filters is near unprecedented in our industry. It’s what sets us apart from other filter manufacturing companies.

While the other guys are splitting their attention between dust collector filters, pool filters, HVAC filters, oil filters, and more, we are working hard to improve and refine the quality of our dust collector cartridge filters. We take the time to explore what works and what doesn’t, and are continuously trying to improve on an already great product.

Our in-house filter experts have years of experience advising companies on the best filter for their specific applications. Let our team recommend the best media for your dust.

Cleaning your Dust Collector Cartridge Filters: Savings vs Risk

Cleaning your dust collector cartridge filters may seem like good way to extend the life of your filters and save money. There are a few reasons why this may not be the best idea for your facility:

1. Reduced Filter Efficiency

Cleaning your filters may actually cause some of the dust and debris to become embedded into the filter media. This reduces the overall filter efficiency, leading to increased emissions and decreased air quality in your facility.

2. Increased Maintenance & Downtime

Cleaning cartridge filters can be quite time-consuming and labor-intensive. This leads to increased downtime to your dust collector, and then any downtime that happens as a result of the dust collector being out of commission.

3. Damaged Filters

Because cartridge filters are designed to receive an even distribution of compressed air, the concentrated blast in one area may cause tears or holes in the media during the cleaning process.

4. Potential Health Risks

Cleaning filters can pose health risks to the person doing the cleaning as they are at risk of inhaling dangerous particulates. Moreover, it can also lead to long-term issues for other employees when the filters are reinstalled. Any damage to the filter during cleaning can cause hazardous dust to re-enter the facility, thereby increasing the health risks for all employees.

Time to Change Your Dust Collector Filters?

If your differential pressure gauge is sitting consistently at 5″ W.G., it’s time to change filters. Don’t try to drag a few extra months of life out of them. Continuing to use filters that are beyond their useful life can damage your air filtration system. We make finding, buying, and receiving your new filters simple and cost-efficient.

MAKE OUR FILTERS

YOUR FILTERS

Private Labeling

Custom boxes and labels to keep your brand consistent

Blind Shipping

Discreet shipping options for your protection

Custom Media Colors

Media to match the box, label, and your branding

Control of Brand Loyalty

Filters labeled with your name to increase repeat orders

Our ServiceMAXX team can help.

We know our job continues long after your filters leave our facility. Whether you need troubleshooting assistance, or simply someone to change your filters, our ServiceMAXX team is there to help. Our products come with the peace of mind that you have a team of experts just a phone call away.

System Inspection & Preventative Maintenance

Our technicians will inspect common wear items. They can also perform preventative maintenance and recommend replacement parts to prevent downtime.

Cartridge & Bag Filter Changeout

Whether you’ve got a twelve cartridge dust collector or hundreds of baghouse filter bags, our team of dust collector experts can keep your equipment running efficiently.

Dye Testing

Leaky filters may lead to ineffective dust collection. Our technicians can conduct a simple dye test to determine if your filters have a leak and need to be replaced.

Ordering Replacement Dust Collector Filters

To place an order for filters, please feel free to call us. You can also fill out the form below, and one of our team members will contact you. If you can locate a part number for your current filters, please have that information available. If not, we can still help you!

For many of our customers, our replacement dust collector cartridge filters not only fit your system perfectly, but provide a huge performance improvement. See some of these case studies to hear what our returning customers say about our filters:

“We will definitely be replacing our stock with Imperial filters when the new budget year rolls around!” (trade school application)

“The cost has been more competitive and the quality has been much better. The cartridge itself is much more durable compared to what we used in the past. Every time we have asked for a quote or response, we have always gotten a fast response. The information we got from Imperial about their DeltaMAXX filters has been as advertised. The product is less expensive and the quality is better.” (lead dust application)

“I’ve been changing filters here in our plant for over 20 years. I wish I would have known about DeltaMAXX filters years ago. We have a system here that I would change at least three times a year. Since we put the Imperial Systems filters in our dust collectors, I haven’t changed them in over a year.” (metal plating application)

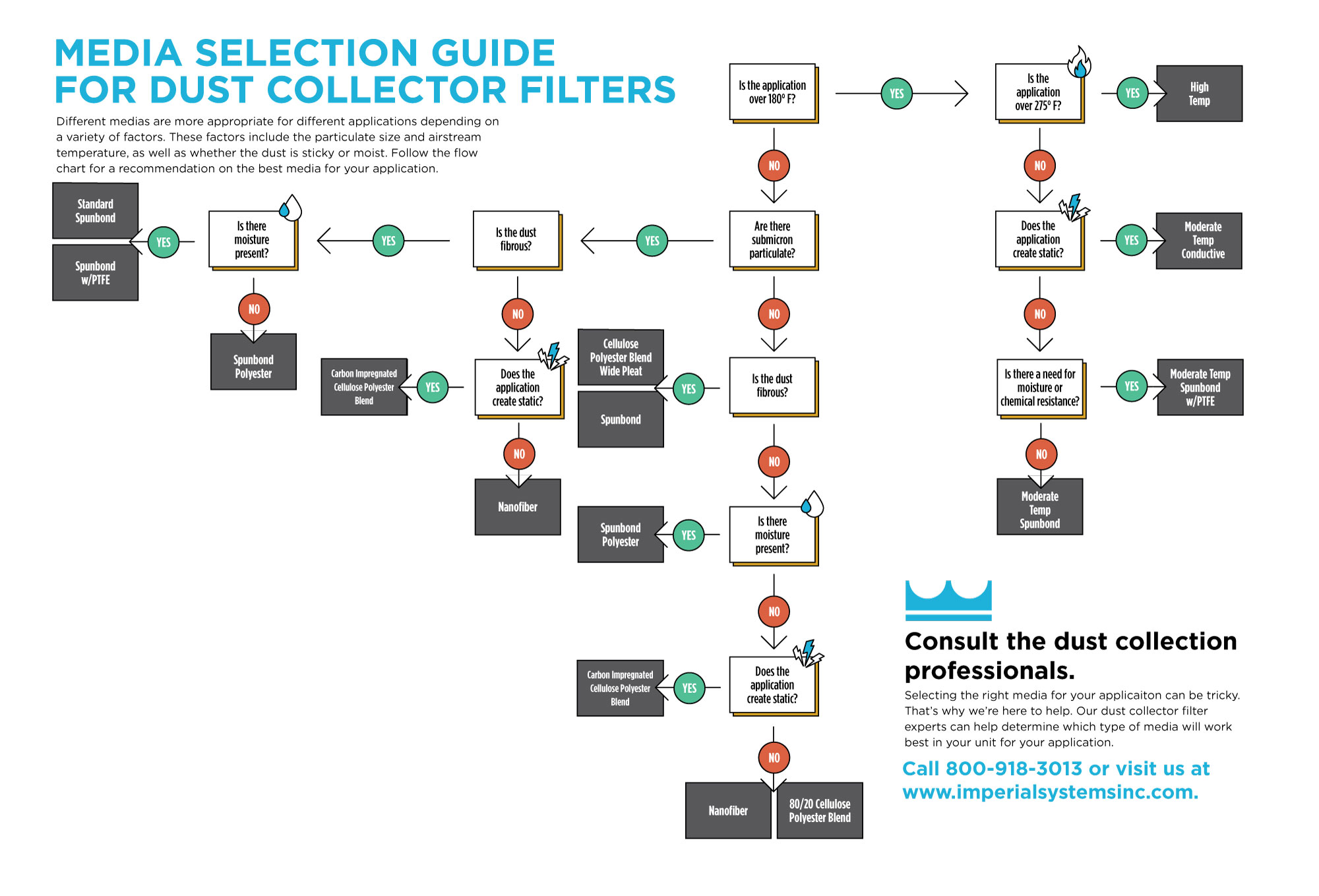

What types of industrial dust collector filter media is best for specific applications?

Selecting the best type of dust collector cartridge filter media for a specific application depends on several factors, such as the type of dust or particulate matter being generated, the operating conditions of the dust collection system, and the filtration efficiency and airflow requirements of the system. Here are some common types of industrial dust collector filter media and their recommended applications:

- Polyester filter media is commonly used for general-purpose dust collection applications, such as woodworking, metalworking, and other industrial processes that generate dry dust or particulate matter. It is resistant to moisture, and its low cost makes it an attractive option for applications with low-to-moderate dust loads.

- Cellulose filter media is ideal for applications that generate moist or humid dust, such as food processing, pharmaceuticals, and some chemical processes. It offers good filtration efficiency and is biodegradable, making it an environmentally friendly option.

- Polypropylene filter media is best suited for applications that generate oily or greasy dust or require high-temperature resistance. It offers excellent chemical resistance and can handle temperatures up to 180°F.

- PTFE (polytetrafluoroethylene) membrane filter media is recommended for applications that generate fine dust or submicron particles, such as cement, pharmaceuticals, and some chemical processes. It offers high filtration efficiency and can handle high temperatures and corrosive environments.

- Nanofiber filter media is a newer technology that offers high filtration efficiency, low-pressure drop, and extended filter life. It is recommended for applications that generate fine or submicron particles, such as welding, metalworking, and some industrial processes.

How often should industrial dust collector filters be replaced?

The frequency of replacing dust collector cartridge filters depends on several factors, including the type of application, the type of filter media, the volume of dust generated, and the quality of the filter itself. Here are some general guidelines for replacing industrial dust collector filters:

- Check the differential pressure: Differential pressure is the difference between the pressure on the dirty side of the filter and the clean side of the filter. A gradual increase in differential pressure is an indication that the filter is becoming clogged and needs to be replaced. A properly sized fan in a dust collection system will allow for a set amount of differential pressure loss. Check the original design of your system to determine the designed differential pressure loss allowed for the filters in your system. This is the most used filter replacement indicator.

- Follow manufacturer’s recommendations: The manufacturer of the filter or the dust collection system may provide recommended replacement intervals based on the specific application and filter media. It is important to follow these recommendations to ensure the proper performance of the dust collection system.

- Monitor the filter efficiency: Some air permits require the efficiency of the filter to be tested periodically using a particle counter to measure the number of particles in the air before and after passing through the filter. If the filter is not capturing the required number of particles, it may be time to replace it.

- Visual inspection: Regular visual inspection of the filter can help identify signs of wear or damage that may require replacement. Signs of wear may include tears or holes in the filter media or cracks or damage to the filter housing. An inspection of the dust source can also indicate something may be off in the dust collector. You may lose suction with clogged filters and less dust will be extracted.

In general, dust collector cartridge filters should be replaced when they become clogged or when their efficiency is reduced to a level that no longer meets the requirements of the application. The frequency of replacement can vary widely, from several months to several years, depending on the specific application and conditions.

What is the expected service life of dust collector cartridge filters?

The expected service life of dust collector cartridge filters cannot be accurately predicted because it is dependent on a variety of factors. Factors such as the type of dust being collected, the type of filter media, the dust volume, and other variables can all impact the lifespan of the filters. For example, filters used in applications with high dust loads or particularly abrasive dust may need to be replaced more frequently than those used in applications with lower dust loads. Similarly, different cartridge filter media types may be better suited for certain types of dust, and the quality of the filters can also impact their service life. Because of these variables, accurately predicting the service life of dust collector cartridge filters is difficult. It is important to monitor the filters regularly and replace them as needed to ensure effective dust collection.

What is the difference between baghouse style filters and cartridge style filters?

Baghouse style filters and cartridge style filters are two common types of filters used in industrial dust collection systems. Here are the key differences between the two:

- Design: Baghouse filters are large fabric bags that are hung from a metal frame inside the dust collector. The bags are typically round or oval in shape and can vary in length and diameter. Cartridge filters, on the other hand, are small, cylindrical filters that are installed vertically or horizontally in a cartridge filter housing. The filters are usually made of pleated filter media and can have a variety of shapes and sizes. Pleated filter media allow for more media in a smaller footprint which can reduce the size of the dust collection machine required.

- Replacement cost: Baghouse filters are generally less expensive to replace than cartridge filters because they contain much less filter media per filter. A baghouse typically has many more filters compared to cartridge filters and takes much more time to replace. Cartridge filters, on the other hand, can be more expensive to replace because they are smaller and contain more filter media. We suggest when determining the full replacement cost of filters that you include the time it takes and cost per square foot of media in each filter.

- Space requirements: Baghouse dust collectors may require more floor space than cartridge filters because they require more filters in the machine. Baghouses are also typically taller which also limits where they can be installed.

Overall, both baghouse style filters and cartridge style filters have their advantages and disadvantages, and the choice of dust collector and filter type depends on the specific application, dust collection requirements, and other factors.

What is the average cost of dust collector cartridge filters?

The average cost of dust collector cartridge filters can vary widely depending on factors such as the size and type of filter, the filtration efficiency, and the filter media. On average, dust collector cartridge filters can range from less than a hundred dollars to several hundred dollars each. It is important to note that the cost of the filters is just one factor to consider when choosing a filter, as the quality and performance of the filter are also important factors to consider. In addition to the initial cost of the filter, it is also important to consider the long-term maintenance and replacement costs to ensure that the most cost-effective solution is selected for the specific application.

What is the filtration efficiency rating of different types of dust collector cartridge filters?

The filtration efficiency rating of dust collector cartridge filters can vary depending on the type of filter media used and the specific application. Every media manufacturer can produce a variety of efficiencies for each media type. The efficiency is also directly related to the dust particle size in your application. Speak with your dust collection expert to review the media efficiency options that are best for you.

What are the maintenance requirements for dust collector cartridge filters?

Proper maintenance of industrial dust collector filters is essential for efficient and effective dust collection. Here are some general maintenance requirements for industrial dust collector filters:

- Proper handling: Filters should be handled carefully to avoid damage to the filter media. Filters should be stored upright in a clean and dry area to prevent contamination. Filters damaged due to improper handling may be rendered inefficient or useless.

- Monitoring: Monitoring the differential pressure across the filters can help identify when they need to be replaced. Differential pressure readings should be taken on a regular basis to ensure that the system is operating at peak efficiency.

- Replacement: Filters will eventually need to be replaced once they reach the end of their service life. The replacement frequency will depend on several factors such as the application, the type of filter media, and the quality of the filter.

What are the environmental regulations for dust collector cartridge filters?

The environmental regulations for dust collector cartridge filters vary depending on the country and region. Here are some general regulations that apply to many industrialized countries:

- Emissions standards: Emissions standards are regulations that limit the amount of pollutants that can be released into the environment. Many countries have emissions standards that apply to industrial dust collection systems. These standards may specify the maximum allowable concentration of various pollutants in the exhaust air.

- Waste disposal regulations: The disposal of used dust collector filters and collected dust is subject to regulations in many countries. These regulations may require that they are disposed of in a certain way, such as through incineration or landfill.

- Occupational health and safety regulations: Occupational health and safety regulations may apply to the operation and maintenance of industrial dust collection systems. These regulations may require that workers be protected from exposure to hazardous dusts and that proper safety equipment be provided.

- Noise regulations: Industrial dust collection systems can generate significant noise levels. Noise regulations may limit the amount of noise that can be generated by these systems to protect workers and nearby residents.

- Hazardous waste regulations: If the dust collected by the system contains hazardous materials, it may be subject to hazardous waste regulations. These regulations may require that the waste be disposed of in a certain way and that special precautions be taken during handling and transportation.

It is important to consult with local environmental regulatory agencies to determine the specific regulations that apply to industrial dust collection systems in your area. Compliance with these regulations can help protect the environment and ensure the safety of workers and nearby residents.