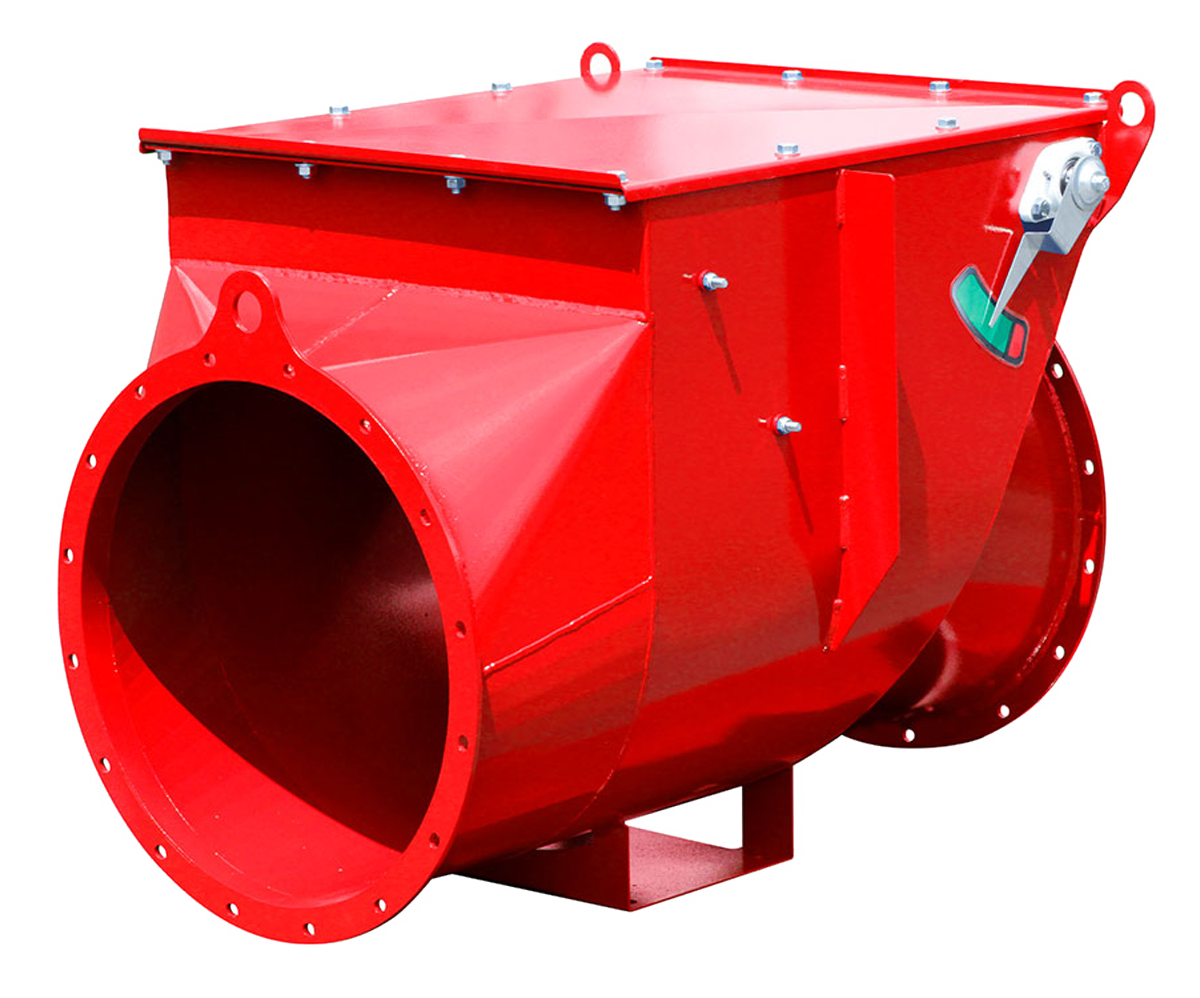

Explosion Isolation Valves

The installation of an explosion isolation device on all suction side ducts that transport material with a Kst value above zero is an NFPA requirement. Installing a Explosion Isolation Valve will protect workers and facilities from the damaging effect of a baghouse or filter explosion.

The Vigiflap is an explosion isolation valve that prevents explosions from spreading downstream in vessels like dust collectors, cyclones, and filters.

The valve stays open when air is flowing or when it is locked in place. This means that the Vigiflap can be used to isolate explosions from both the inlet and outlet of a vessel.

The Vigiflap valve is NFPA 69 compliant and ATEX certified for explosion containment.

The Vigiflap can be used for KSTs under 250 and can be installed at any angle. The flap can be held open with the process airflow or a locking mechanism.

Optional Features

- Galvanized or Stainless Steel Body

- Dust level sensor to prevent dust accumulation

- Connection box installed on the body