by Erin Long | Jan 30, 2019 | Uncategorized

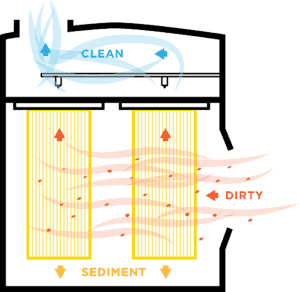

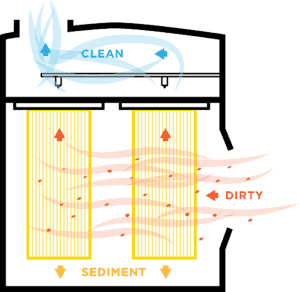

The CMAXX is a vertical pulse-jet dust collection system. So how does a dust collector work? What’s going on inside there, and why is it designed the way it is?

The concept is basic: dirty air goes in, dust or particulate gets removed, and clean air comes out. However, the details become important when you’re looking for the right central vacuum system for your machinery.

Considering a shop dust collector system for your business? If so, this information may be helpful for you.

Dust Collection System Design

The CMAXX is a reverse pulse-jet cartridge dust collector. The best way to explain what this means is to go on a tour of the path that air follows through the dust collection system.

Dirty Air

- Dirty air containing particles of dust enters the collector through the ductwork. Fans either push or pull the air through the ducts.

- The air hits a set of baffles, which are angled pieces of metal that slow it down. As a result, this keeps the dust from hitting the filters at full speed.

- Then the air enters what we call the dirty air plenum. This just means the side of the collector where the air is dirty. At the bottom of this space, collected dust drops out into a drum or hopper.

Dust Capture

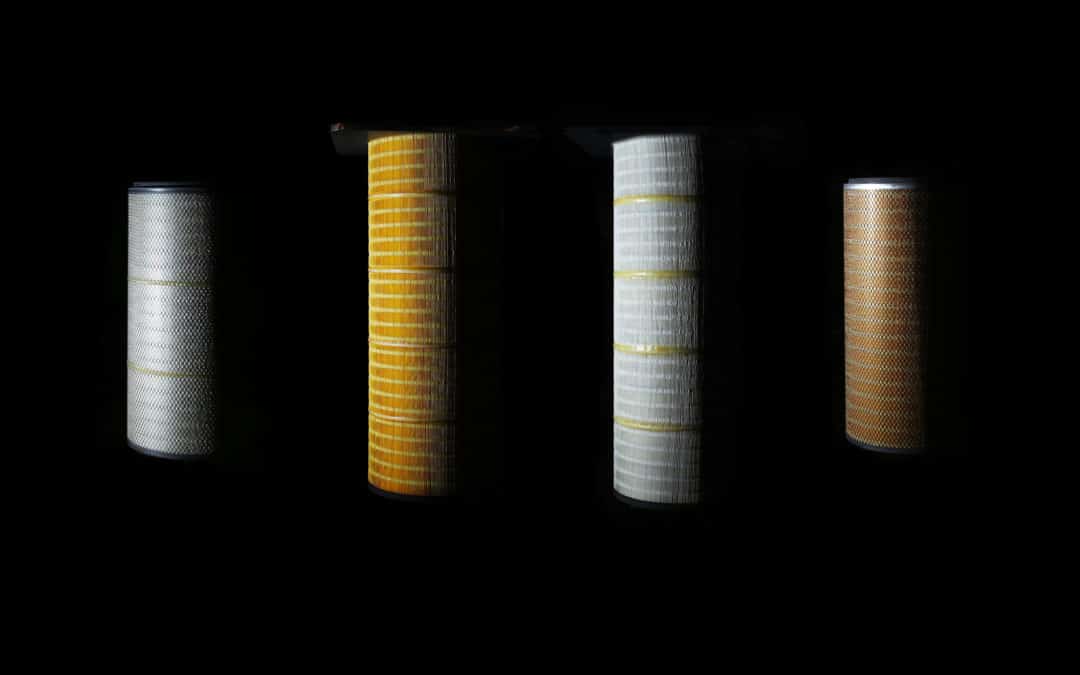

- Next, the air passes through the dust collector’s cartridge filters. In the CMAXX, these hang vertically from the tube sheet, which is the metal sheet separating the dirty and clean air spaces.

- Pleating the filters gives them more surface area. DeltaMAXX filters are also coated with a nanofiber material. This makes the spaces that the air must go through smaller.

- The filters capture the dust. Some of it falls off. Some of it sticks to the filters. Gaskets at the top of each filter seal it to the tube sheet to keep dust from sneaking through.

Filter Cleaning

- A pulse of compressed air blows into the filters. Because the pulse of compressed air goes in the reverse direction of the regular airflow, we call it a reverse pulse-jet collector.

- The pulse of compressed air blows the accumulated dust off the filters. The dust drops out of the collector and the filters are ready to collect more dust.

- On the other side of the filters, filtered air enters the clean air plenum. From there, it can go back into the facility or vented outside.

How Does the Pulse-jet Dust Collection System Clean the Cartridge Filters?

A pulse-jet collector is a very effective type of industrial dust collection system. Diaphragm valves control the compressed air in a pulse-jet collector. Often a timer controls the diaphragm valves. To make the cleaning more efficient, the pulses can also be controlled by differential pressure sensors.

Differential pressure sensors read the air pressure on the dirty air and clean air sides of the filters. The dirtier the filters are, the more resistance they have to air going through them. When the difference in the two pressure readings gets too high, it signals the filter cleaning mechanism.

Using differential pressure sensors makes a pulse-jet dust collector more efficient because it reduces the use of compressed air. It also helps the cartridge filters last longer, because the pulses of compressed air cause wear and tear on them.

Pulse-jet dust collection systems are efficient because of this filter cleaning. With an industrial dust collection system, replacement filters can be a big expense. By making filters last longer, a pulse-jet collector is the most cost-efficient shop dust collection system. Read about offline cartridge filter cleaning.

How Does a Vertical Pulse-jet Dust Collection System Work Better?

Cartridge collectors have the filters in either a horizontal or vertical arrangement. In horizontal dust collection system design, the filters lay on their sides and are stacked on top of each other. The filters hang down from the tube sheet in a vertical filter dust collector.

In a horizontal pulse-jet dust collector, the pulse cleaning causes dust to be blown off the filters. However, because they’re on top of each other, the dust from the top filters falls on top of the others.

In a vertical pulse-jet collector, the dust that pulses off of the filters drops directly down into the hopper. The dust falls free and doesn’t land on the other filters.

Most CMAXX competitors on the market are horizontal dust collectors. Only a few companies make vertical pulse-jet cartridge collectors. Vertical systems are the most effective shop dust collection systems.

In conclusion…

If you’re looking for a central machinery dust collector for your facility, make sure it has a self-cleaning, pulse-jet system. To get a good idea of how the CMAXX works, check our product page. If you still have questions, please feel free to ask us!

Read more

by Erin Long | Jan 28, 2019 | Uncategorized

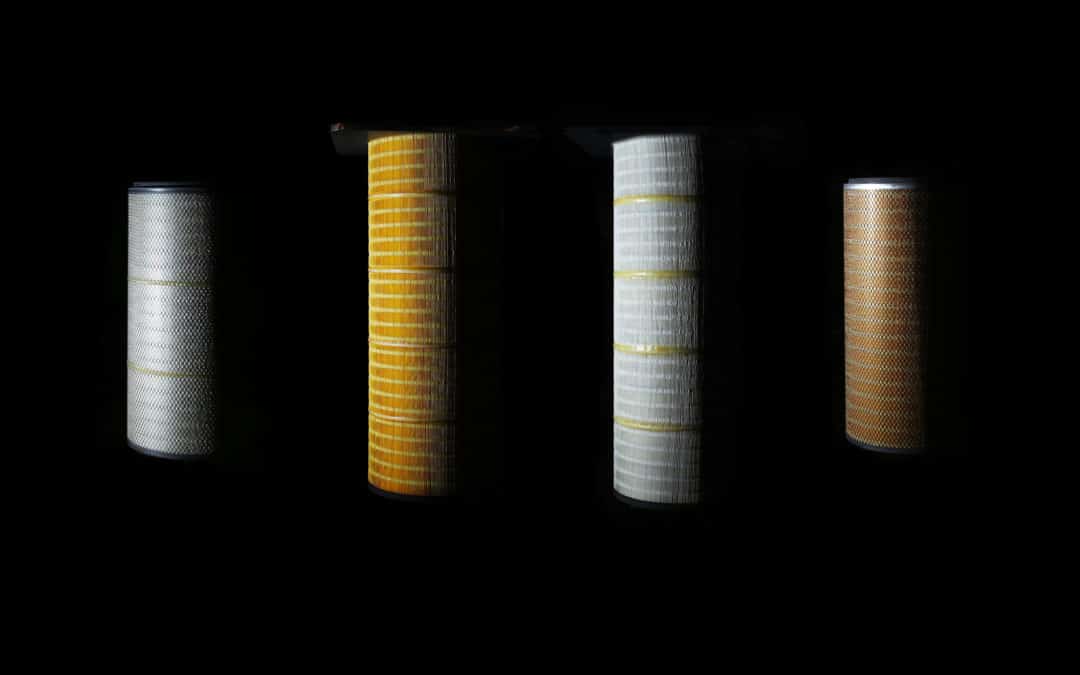

After you’ve installed your dust collection system, the big initial expense is over. However, you need to plan for your system’s regular maintenance, like replacing the industrial dust collector cartridge filters. Dust collectors that use cartridge filters have become very popular, partly because cartridge filter changes are easier.

Dust collector filters are the part of the system that clean the air traveling through the system. In a pulse jet collector with dust cartridge filters, the filter cleaning system removes dust from the surface of the filters.

All filters, though, will eventually become overloaded with particles and will need to be replaced.

Do they really have to be replaced? Why can’t you just clean them?

Can’t you just take out and clean the dust collector cartridge filters so they’ll work better again?

You can, and people do. But you shouldn’t, and here’s why.

You can measure the efficiency of a dust cartridge filter by its differential pressure. This means measuring the pressure on the dirty air side of the filter and then on the clean air side. This tells you how much the airflow is slowing down across the filters.

If your differential pressure is higher than the recommendation for your system, it’s time for a change. The filter cleaning system is not able to clean your dust collector filters anymore. It’s time to replace the filters.

There are companies that offer to clean your industrial dust collector filters instead of changing them. Usually, they do this by blasting them with high-pressure compressed air to blow the accumulated dust out of the filters. The problem is that dust collector cartridge filters are made of cellulose and polyester, which means a large part of the filter is cardboard. When you try to clean industrial dust collector filters this way, the high-pressure air will create holes in the filter material.

You might not be able to see the holes. It may seem like the filter cleaning worked perfectly. The filters get put back in the dust collector, and the differential pressure is much lower.

The pressure isn’t lower because the filters are clean, though. It’s lower because air is going straight through the little holes torn in your filter.

How big a problem are those little holes in the cartridge filters?

Cleaning your dust collector filters can put holes in them, but how much dust is really going to get through those tiny holes? The answer is “a lot”. Air follows the path of least resistance. The filter material has resistance. The holes don’t. The air going through the dust collector cartridge filters will go through the holes, taking dust with it.

This is a serious problem for several reasons.

First, dust will be getting through your dust collector filters. Depending on where your air is venting, it’s going out into the environment or back into your facility. Either way, this could result in fines or health problems for employees.

Second, dust that gets through the filters can build up in the clean air plenum. There should never be dust in this part of the collector. The dust in there will keep blowing out into the facility even if you fix the filters.

Third, the differential pressure will be lowered because air can easily get through the holes. This could make it look like the filters are clean and working well, even though they are damaged. This makes it hard to recognize that the dust collector filters are not doing their job.

You’re Not Saving Money by Cleaning Your Dust Collector Cartridge Filters

Industrial dust collector filters are made of a cardboard-based material that is not made to be cleaned and re-used. While it looks like the filters are cleaned and working better, what you’re really seeing is filters that have been damaged. Learn more about filter cleaning versus installing new filters and offline cartridge filter cleaning.

Instead of trying to save money by having your filters cleaned, contact Imperial Systems and ask us about DeltaMAXX filters. They last longer than the competitors’ filters, so you’ll save money on your industrial dust collector filters over time.

Read more

![Weld Fume Extraction Guide [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/01/fume-extraction-header-1080x675.jpg)

by Erin Long | Jan 23, 2019 | Weld Fume

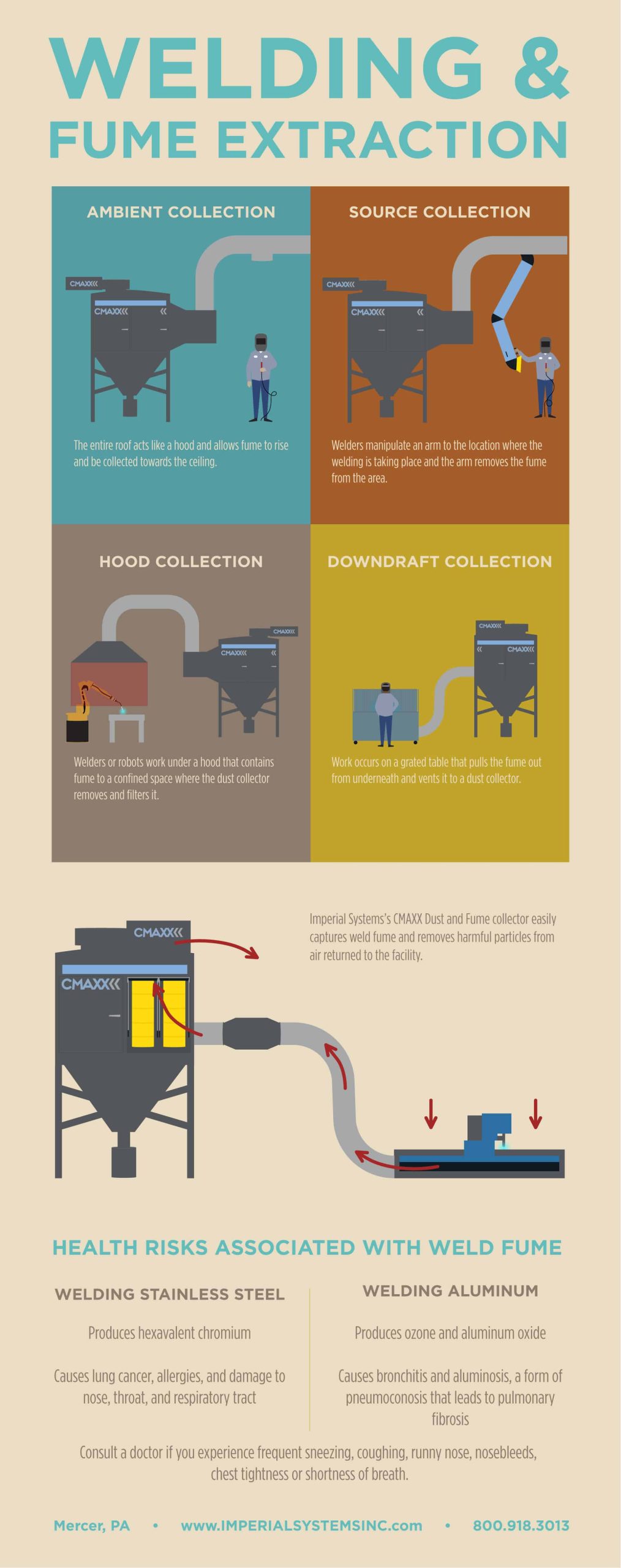

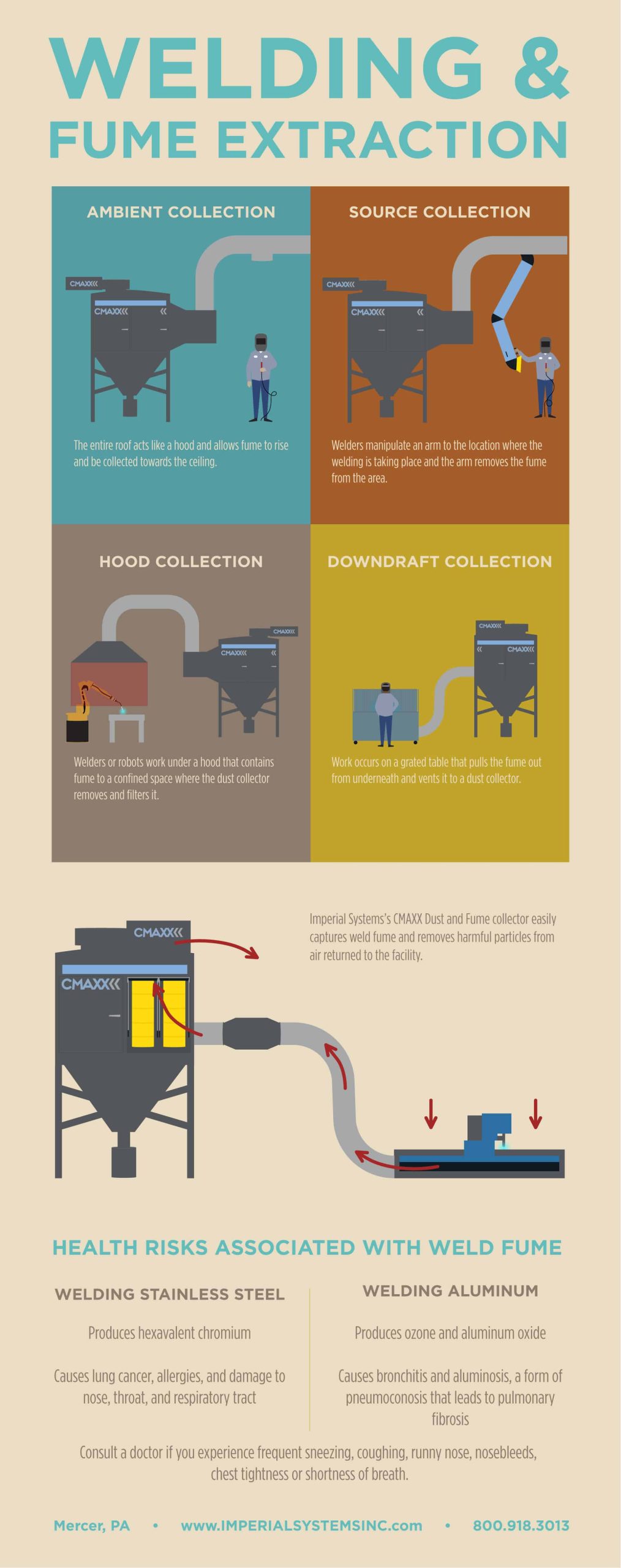

This weld fume extraction guide takes a look at the many ways to collect and remove weld fume from a facility. When not properly taken out of the work area, weld fume can cause some serious health issues for welders.

Weld Fume Extraction Methods

- Ambient Collection – The entire roof acts like a hood and allows fume to rise and be collected towards the ceiling. Ductwork runs with inlets above the work area to clear the fumes.

- Source Collection – Welders manipulate an arm to the location where the welding is taking place and the arm removes the fume from the area.

- Hood Collection – Welders or robots work under a hood that contains fume to a confined space where the dust collector removes and filters it.

- Downdraft Collection – Work occurs on a grated table that pulls the fume out from underneath and vents it to a dust collector.

Health Risks Associated with Weld Fume

Welding Stainless steel

- Produces hexavalent chromium, a dangerous valence state of the element chromium. Chromium metal is added to alloy steel to increase hardenability and corrosion resistance.

- Causes lung cancer, allergies, and damage to the nose, throat, and respiratory tract

Welding Aluminum

- Produces ozone and aluminum oxide. TIG, MIG, and plasma-arc welding typically produce ozone, a highly toxic gas. Aluminum oxide forms from the base and filler materials and exists in the welding fumes.

- Causes bronchitis and aluminosis (aluminum lung), a form of pneumoconiosis that leads to pulmonary fibrosis

Consult a doctor if you experience frequent sneezing, coughing, runny nose, nosebleeds, chest tightness, or shortness of breath.

Weld Fume Extraction Equipment and Experts

The CMAXX Dust & Fume Collector by Imperial Systems is the best choice for removing weld fume from your facility and keeping your employees safe. Our sales and product engineers will design and dust and weld fume collector specifically for your application. Contact us today.

Read more

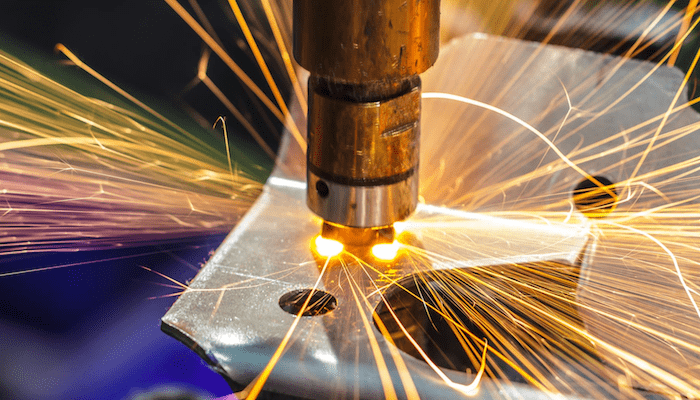

by Erin Long | Jan 21, 2019 | Metal Cutting

Most of the companies we work with have a good record for factory safety. With OSHA safety regulations, there’s been a big push for factories to remove hazards from the work area.

One area that sometimes gets missed is the handling of dust and fumes. This is very important in metalworking industries. Metal dust creates unique problems, and a safety plan must take these into account. Here are some safety tips for factory workers as well as their plant leaders.

Factory Safety Tip #1: TREAT ALL METAL DUST AS COMBUSTIBLE

Unless you have had your dust tested, you should assume that metal dust is combustible.

Because of proper fire and explosion safety devices, many metal dust fires are confined to the dust collector. However, one example from the Chemical Safety Board (CSB) shows how improper handling of metal dust is a safety hazard.

The safety failure occurred in a plant in West Virginia working with titanium metal and powder. Titanium is a very combustible metal, and it was being stored in open containers throughout the facility. Sparks generated from a mixing machine ignited the powder. (See the CSB’s investigation of this incident here.)

Another explosion occurred on January 3, 2019 in a metal recycling factory. A machine shredding metal scraps into powder caused an explosion that blew out a wall and burned several workers. These types of incidents are obvious safety hazards.

Metal fires burn at anywhere from 5000 to 8000 degrees F. Once they have ignited, they are extremely hard to put out. The best factory safety solution is to do a hazard check of the facility and eliminate two key elements: the presence of loose combustible dust and the presence of ignition sources.

Manage the dust with a dust collection system equipped with proper safety features. A correctly designed dust collector is one of the most important pieces of factory dust control equipment. Getting rid of ignition sources might mean checking all machinery regularly for malfunctions or overheating. It also means having a safety plan in place for all repairs, especially hot work, done in the factory.

Factory Safety Tip #2: DON’T TREAT A METAL FIRE LIKE AN ORDINARY FIRE

Metal fires cannot be put out with water. They cannot be put out with commercial ABC extinguishers that are part of many factory safety plans. This safety tip can make the difference between extinguishing and fueling a metal fire.

Only a Class D fire extinguisher can put out metal fires. Why can’t you use water or other typical fire extinguishers?

Metal dust fires burn much hotter than other materials. If water from the factory fire safety system is sprayed on this type of fire, some of the water will turn to scalding steam. The rest of the water will break down to hydrogen and oxygen. Both gasses are flammable. It’s just adding fuel to the fire, as confirmed in this article by Fire Engineering.

Any facility that produces or handles metal dust should have a safety plan that includes Class D extinguishers. Another key safety tip is that there must be clear exits so people can escape quickly. A metal fire can burn very fast and destroy a building in minutes.

Factory Safety Tip #3: MAKE SURE YOUR SUPPLIER DESIGNS YOUR DUST COLLECTION SYSTEM FOR METAL DUST

Metal dust from cutting, welding, or grinding is very fine, often less than 0.3 microns. It is also usually combustible. Inside a dust collector and under pressure, it is explosive. A dust collection system that meets NFPA standards will improve plant safety.

Equip dust collectors that handle combustible dust with devices to detect, isolate, and extinguish flames or explosions. Without devices to isolate a deflagration and vent it away from people and buildings, factory safety could be at risk.

A key safety tip is to make sure that the company who builds and installs your dust collection system understands and can explain all of the required fire safety equipment to you.

Another important safety tip is to make sure to keep this equipment in good working order. This includes changing the filters when they need it and having regular inspections and maintenance on the collector.

By following these tips, you can greatly improve plant safety and decrease the hazards of metal dust and fumes.

Read more

by Erin Long | Jan 17, 2019 | Uncategorized

The basic answer is that yes, a dust explosion is more likely during this season. The U.S. Chemical Safety Board found that since 1995, 7 out of 8 serious dust explosions occurred in the winter. February was the most dangerous month.

Why does dust explode more often in the winter? There are several factors responsible:

DRY AIR AND LOW HUMIDITY

When the air is cold and dry in the winter, dust contains less moisture. This means it can become airborne more easily. Clouds of dry airborne dust can ignite quickly. Make sure the dust collection system is in good working order and get rid of any escaped dust as soon as possible to prevent this situation.

What if you live in an area where the humidity is always low? This creates the same risks that dry winter air creates in other places. A combustible dust explosion is more likely to occur any time that the air is dry.

STATIC CHARGES

Dry air encourages static electricity charges to build up more easily than when the air is humid. A spark from static electricity can be enough to ignite a combustible dust explosion. Many of the dust collectors we’ve seen when doing maintenance visits are not properly grounded, or not grounded at all.

The best way to prevent the buildup of static electricity in the dust collection system (and other places) is to properly ground all dust-handling equipment. This is an important protective measure no matter what season it is.

The fact that so many systems are not grounded shows why your experienced professionals should design and install your dust collection system.

HOUSEKEEPING

Some facilities keep doors, windows, and vents open during warm weather, which increases natural airflow. In the winter, though, it means lost heat which means lost money. Most places are sealed up as much as possible in the winter to keep the cold out, but this also keeps the dust in. Shops that count on open doors and vents to keep the air clean in the summer might be at risk of a dust explosion in the winter.

Some facilities keep doors, windows, and vents open during warm weather, which increases natural airflow. In the winter, though, it means lost heat which means lost money. Most places are sealed up as much as possible in the winter to keep the cold out, but this also keeps the dust in. Shops that count on open doors and vents to keep the air clean in the summer might be at risk of a dust explosion in the winter.

Dust buildup inside the facility in winter can also cause a dangerous situation: the potential for a secondary explosion. These happen when dust builds up somewhere, which can happen on any flat surface.

This is more likely to happen in a closed-up shop in the winter. However, it can happen any time. Secondary dust explosions happen when a first, smaller explosion happens. This might not be that bad, but the secondary dust explosion can be much worse. The first explosion blows all the accumulated dust into the air, and then it can ignite in a much bigger explosion.

IGNITION SOURCES

Heaters get turned on in the winter. There’s a good chance they haven’t been turned on since last winter. They can act as an ignition source, especially if they have any faulty wiring. Just one spark is enough for ignition. This has led to some of the worst combustible dust explosions in recent history.

In already dry winter conditions, a spark from a damaged heater is even more likely to ignite an explosion. Sparks from static can also cause ignition.

DUST CONTROL

For dust to ignite, the classic “fire triangle” has to be present: fuel (combustible dust), oxygen, and an ignition source. If you remove any of those things, you can stop a dust explosion from occurring.

Because you can’t guarantee a lack of ignition sources, the best solution is to remove the fuel. A dust collection system fitted with appropriate NFPA safety devices can remove dust from your facility. With explosion isolation valves and other safety features, the dust collection system can also control a dust explosion and vent it safely.

As an added bonus, a dust collection system with high efficiency nanofiber DeltaMAXX filters can usually return air to your facility after filtering. This means that in the winter, the dust gets removed, but the heat stays inside where it belongs.

DON’T HAVE A WINTER WHERE YOU ARE?

Not everyone can be lucky enough to enjoy the ice, snow, and frigid weather of a Pennsylvania winter like we are. Maybe where you’re located, there isn’t really a cold season where the doors are closed or the heaters are on.

Do you have a dry season? During any time when the humidity is low, you have an increased risk of a combustible dust explosion.

Besides, steps, like grounding your equipment, removing ignition sources, and cleaning up your dust, are always a good idea no matter where you’re located.

Read more

![Weld Fume Extraction Guide [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2019/01/fume-extraction-header-1080x675.jpg)