FACTORY SAFETY TIPS FOR HANDLING METAL DUST AND FUMES

Most of the companies we work with have a good record for factory safety. With OSHA safety regulations, there’s been a big push for factories to remove hazards from the work area.

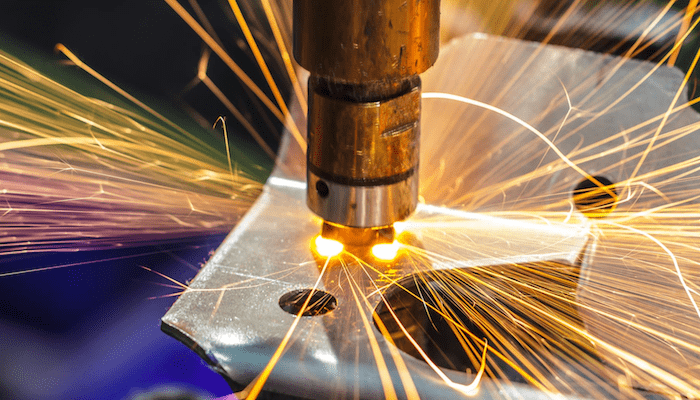

One area that sometimes gets missed is the handling of dust and fumes. This is very important in metalworking industries. Metal dust creates unique problems, and a safety plan must take these into account. Here are some safety tips for factory workers as well as their plant leaders.

Factory Safety Tip #1: TREAT ALL METAL DUST AS COMBUSTIBLE

Unless you have had your dust tested, you should assume that metal dust is combustible.

Because of proper fire and explosion safety devices, many metal dust fires are confined to the dust collector. However, one example from the Chemical Safety Board (CSB) shows how improper handling of metal dust is a safety hazard.

The safety failure occurred in a plant in West Virginia working with titanium metal and powder. Titanium is a very combustible metal, and it was being stored in open containers throughout the facility. Sparks generated from a mixing machine ignited the powder. (See the CSB’s investigation of this incident here.)

Another explosion occurred on January 3, 2019 in a metal recycling factory. A machine shredding metal scraps into powder caused an explosion that blew out a wall and burned several workers. These types of incidents are obvious safety hazards.

Metal fires burn at anywhere from 5000 to 8000 degrees F. Once they have ignited, they are extremely hard to put out. The best factory safety solution is to do a hazard check of the facility and eliminate two key elements: the presence of loose combustible dust and the presence of ignition sources.

Manage the dust with a dust collection system equipped with proper safety features. A correctly designed dust collector is one of the most important pieces of factory dust control equipment. Getting rid of ignition sources might mean checking all machinery regularly for malfunctions or overheating. It also means having a safety plan in place for all repairs, especially hot work, done in the factory.

Factory Safety Tip #2: DON’T TREAT A METAL FIRE LIKE AN ORDINARY FIRE

Metal fires cannot be put out with water. They cannot be put out with commercial ABC extinguishers that are part of many factory safety plans. This safety tip can make the difference between extinguishing and fueling a metal fire.

Only a Class D fire extinguisher can put out metal fires. Why can’t you use water or other typical fire extinguishers?

Metal dust fires burn much hotter than other materials. If water from the factory fire safety system is sprayed on this type of fire, some of the water will turn to scalding steam. The rest of the water will break down to hydrogen and oxygen. Both gasses are flammable. It’s just adding fuel to the fire, as confirmed in this article by Fire Engineering.

Any facility that produces or handles metal dust should have a safety plan that includes Class D extinguishers. Another key safety tip is that there must be clear exits so people can escape quickly. A metal fire can burn very fast and destroy a building in minutes.

Factory Safety Tip #3: MAKE SURE YOUR SUPPLIER DESIGNS YOUR DUST COLLECTION SYSTEM FOR METAL DUST

Metal dust from cutting, welding, or grinding is very fine, often less than 0.3 microns. It is also usually combustible. Inside a dust collector and under pressure, it is explosive. A dust collection system that meets NFPA standards will improve plant safety.

Equip dust collectors that handle combustible dust with devices to detect, isolate, and extinguish flames or explosions. Without devices to isolate a deflagration and vent it away from people and buildings, factory safety could be at risk.

A key safety tip is to make sure that the company who builds and installs your dust collection system understands and can explain all of the required fire safety equipment to you.

Another important safety tip is to make sure to keep this equipment in good working order. This includes changing the filters when they need it and having regular inspections and maintenance on the collector.

By following these tips, you can greatly improve plant safety and decrease the hazards of metal dust and fumes.

Read more