The cartridge-type dust collector has become a popular option for industrial dust and fume control. How does this type of collector work, and why would you want to use one?

In many industries, people recognize the term “baghouse” as a general type of dust collector. If you are looking for information about how a baghouse works, please see our baghouses blog post. Sometimes, we find that when people refer to baghouses, they may use the term for all industrial dust collectors. A cartridge collector offers advantages you may want to consider.

What is a Cartridge Type Dust Collector?

An industrial cartridge-type dust collector uses pleated filters. Usually round but sometimes oval or other shapes, these capture dust or fumes on their outside surface. Many have a metal mesh called expanded metal, which may be on the inside, outside, or both. Some do not have expanded metal, and instead, use fabric bands to keep their shape.

An industrial cartridge-type dust collector uses pleated filters. Usually round but sometimes oval or other shapes, these capture dust or fumes on their outside surface. Many have a metal mesh called expanded metal, which may be on the inside, outside, or both. Some do not have expanded metal, and instead, use fabric bands to keep their shape.

Cartridge filters are made from a blend of polyester and cellulose. Manufacturers apply coatings to this material. Nanofiber coating increases filtration efficiency. Spunbond material offers improved durability under some harsh conditions. Less common materials include PTFE (nonstick) coating and hydrophobic/oleophobic (water and oil resistant).

Because of the pleated material, these filters provide much more surface area for filtration. With baghouse filters, you need a lot of bags to equal the surface area of a pleated filter. This makes a cartridge type dust collector ideal as a smaller, less bulky system.

What Happens Inside a Cartridge Collector?

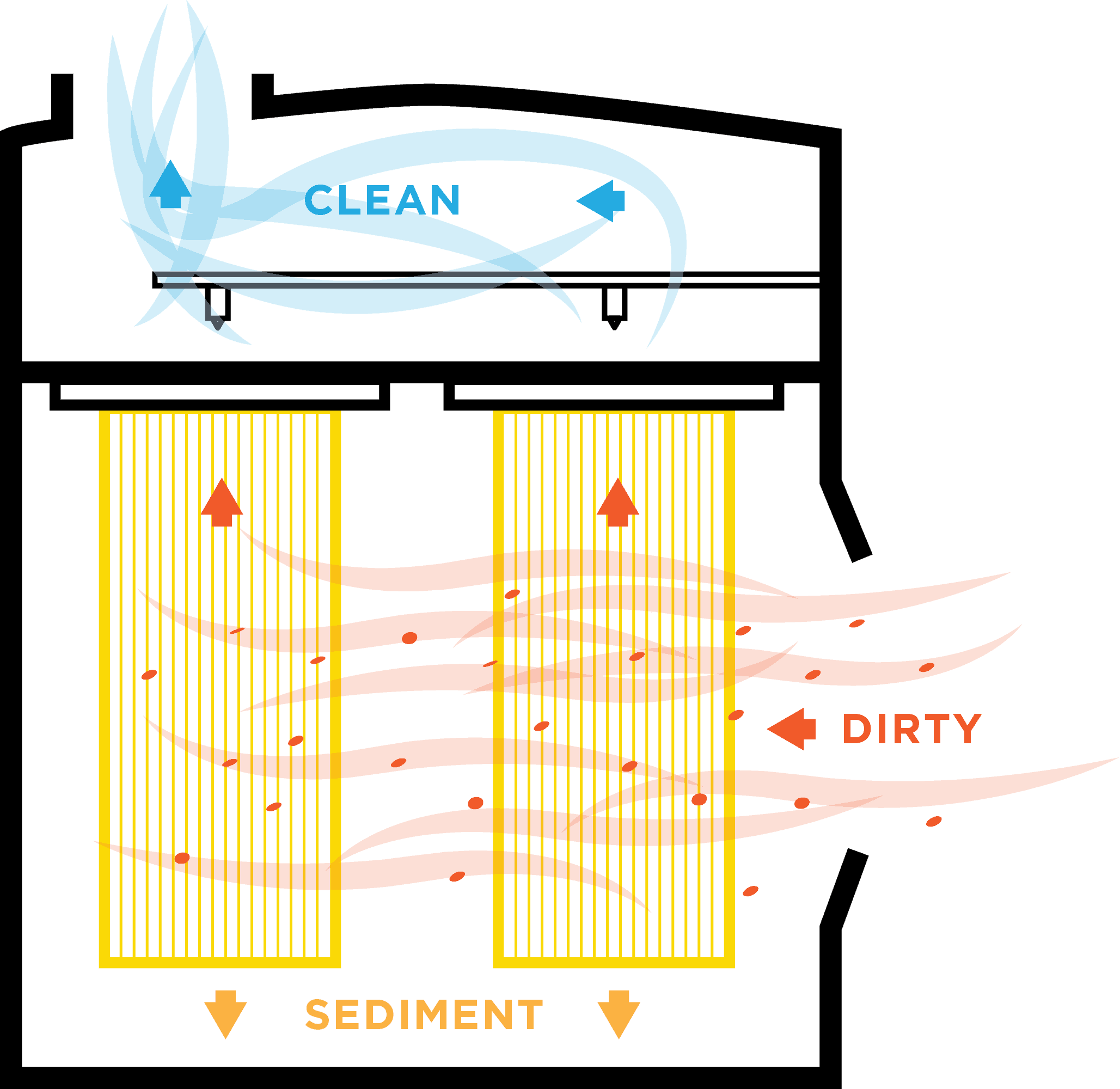

Like most industrial dust collection systems, a cartridge collector uses a fan to move air and dust into the collector, where the filters are. We call this space the DIRTY AIR PLENUM. Air moves through the filters, while dust and particles stay on the outside. The CLEAN AIR PLENUM is the other side of the dust collector after the air has gone through the filters. The sheet of metal where clean air goes through, where the filters are sealed with gaskets, is called the TUBE SHEET.

In some cartridge-type dust collectors, the cartridge filters go in horizontally, lying on their sides. A metal yoke supports them, and gaskets seal them against the doors, between filters, and against the tube sheet. The tube sheet is vertical in the rear part of the collector.

In a vertical cartridge-type dust collector like the CMAXX, the tube sheet is above the filters. One gasket seals the filter to the tube sheet. With no gaskets between filters and no yokes to bend, vertical cartridge collectors maintain a better seal.

How Does a Cartridge Dust Collector Clean Filters?

Vertical and horizontal cartridge collector systems use the same method for cleaning cartridge filters. Pulses of compressed air travel through the filters in the opposite direction that the dirty air goes. These pulses blow dust and particles off the filters so it can fall into the collection container.

Compressed air pulse cleaning keeps cartridge filters working efficiently. Depending on the application, companies can expect several months to a year or more of filter life. Eventually, the filters have accumulated so much dust that they don’t let air flow through them anymore.

This slowed-down airflow is measured as differential pressure. This measures the change in pressure across the filters when the pulse cleaning operates. When the differential pressure gets too high, the filters have reached the end of their functional life.

Some systems operate the pulse cleaning on a timer. This may lead to filters being pulsed when they don’t need it. Since the compressed air blasts cause wear and tear on a filter over time, many systems try to minimize the number of pulses. Some systems only initiate pulse cleaning when the differential pressure reaches a certain point. As a result, filters are only pulsed clean when they need it.

What is a Cartridge Collector Used For?

Cartridge dust collection systems work for many applications. Because the filters can handle very small particles, cartridge filters work very well for applications like welding, laser, and plasma cutting fumes. They also excel in industries like grain and feed dust, fine wood dust, fiberglass, and shot blasting.

Companies increasingly choose cartridge collectors instead of baghouses when they need a smaller, more compact dust collector. In addition, maintenance on a cartridge-type dust collector is much easier. Instead of climbing inside the dirty baghouse and changing hundreds of bags, maintenance workers can pull cartridge filters out without ever getting inside the collector.

With proper venting and NFPA standard safety features, a cartridge-type dust collector can be located inside a building if necessary. Even a small baghouse will not usually fit indoors. For extreme or difficult applications, a cartridge collector can be fitted with special features to improve performance.

Cartridge Collector vs. Baghouse

If someone tells you they have THE answer to this question, don’t listen to them. Neither type of dust collector works for every application.

Cartridge collectors have the advantage of smaller size, increased filter surface area, and easy maintenance. They handle most applications, especially small particles, very efficiently.

Baghouses have an advantage in their ability to tolerate harsher applications. Sticky or abrasive materials, or dust contaminated with oil or moisture, may work better with a baghouse. Bags can also handle extreme high-temperature applications.

Best solution? Talk to a dust collection professional. Preferably, find a manufacturer that sells both types of dust collectors, so they won’t feel pressured into selling you one or the other. Ask about their experience with your application.

Cartridge dust and fume collectors continue to grow in popularity because of the benefits they offer. However, the baghouse continues to have its fans and its uses. Weigh your options before deciding.