Find out what our IDA has to offer your metalworking business.

If you are in the metalworking or manufacturing industries, safety is, by necessity, one of your highest priorities. From the good keeping and proper use of equipment to consistent use of personal safety gear, there are countless things you monitor each day to keep your employees and your workspace safe. But are you doing enough? Or are you at risk for potential combustion due to your dust and fume collection system?

Without IDA (In-line Deflagration Arrester) filters, you and your employees may be at risk. Discover how this proprietary technology from Imperial Systems could prevent disaster in your workshop while reducing your costs and improving your efficiency.

The Danger of Combustion

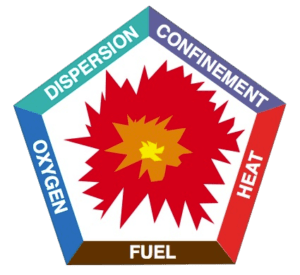

It’s no secret that dust explosions are a common risk in metalworking and manufacturing industries. Processes including welding, grinding, polishing, and more can create the perfect combination of dust and sparks in the air that can lead to serious consequences. For example, three workers were killed in 2010 in a titanium dust explosion in West Virginia. This incident is in addition to the 281 combustible dust incidents identified by the U.S. Chemical Safety and Hazard Investigation Board between 1980 and 2005. In those incidents, 119 workers were killed, 718 injured, and many industrial facilities sustained extensive damage.

It’s no secret that dust explosions are a common risk in metalworking and manufacturing industries. Processes including welding, grinding, polishing, and more can create the perfect combination of dust and sparks in the air that can lead to serious consequences. For example, three workers were killed in 2010 in a titanium dust explosion in West Virginia. This incident is in addition to the 281 combustible dust incidents identified by the U.S. Chemical Safety and Hazard Investigation Board between 1980 and 2005. In those incidents, 119 workers were killed, 718 injured, and many industrial facilities sustained extensive damage.

Recognizing these dangers, OSHA and the NFPA have created standards aimed at minimizing the risks to life and property that are posed by combustible dust. Important steps to reduce the danger of combustion include:

- Analyzing the hazards present in your facilities

- Utilizing an effective dust collection system

- Monitoring this system and others to ensure proper operation

- Limiting smoking, open flames, and sparks in work areas

- Installing spark arresters in dust collection ductwork

More important combustion prevention guidelines and recommendations can be found with the NFPA or OSHA.

The mistake made by many metalworking and manufacturing businesses is to some, but not all, of the recommended safety steps. A dust collection system without an IDA present can still combust, creating a deadly flame front.

Imperial Systems’ IDA Filter Technology

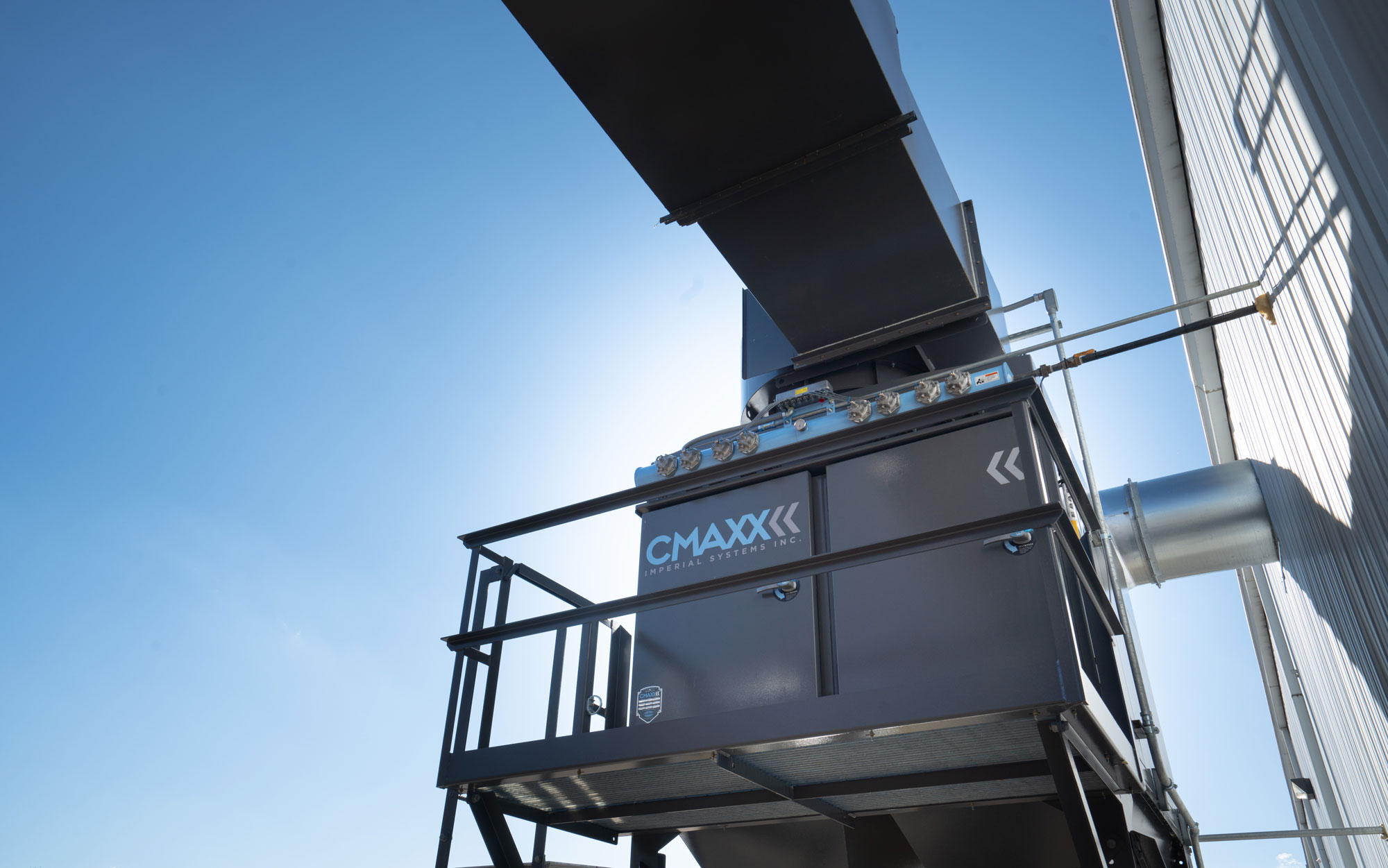

At Imperial Systems, we are proud to announce our proprietary IDA DeltaMAXX filters, which bring advanced safety features to our CMAXX Dust Collection System. Together, they offer excellent protection against combustion.

At Imperial Systems, we are proud to announce our proprietary IDA DeltaMAXX filters, which bring advanced safety features to our CMAXX Dust Collection System. Together, they offer excellent protection against combustion.

In a recent study of the CMAXX Dust Collector with IDA DeltaMAXX filters, backed by third party testing, we found that in all tests the filters were able to isolate a deflagration and stop a flame front. The results showed no trace of flame or spark transmission downstream from the filters or in the clean air plenum.

In fact, the body of the CMAXX Dust Collection System, without explosion venting, was also tested to withstand a deflagration of corn starch at 185 KST with pressures exceeding 4 PSI. In this case, the full explosion diverted through the IDA DeltaMAXX filters. Afterwards, the filters showed no sign of deformation; their internal cages maintained their shape perfectly, and the seals were not deformed or melted either.

Note: Although the test described above was performed without explosion vents, as a demonstration of the worst-case scenario, dust collectors should always be properly vented.“discharged into a safe, unrestricted, outdoor location, and the discharge shall not be obstructed” (See NFPA 69 Chapter 12). Where the CMAXX is vented through a pipe or duct, the duct must be designed to withstand the pressure of an explosion. These pressures can be provided at the time of engineering. Imperial Systems can have your dust tested prior to final engineering to determine the proper venting calculations.

Comprehensive Combustion Safety

In addition to their high performance in the above testing, the CMAXX Dust Collector with IDA DeltaMAXX cartridge filters also offers several advantages over similar systems that have been tested. These include:

- Elimination of the need for expensive after-filters that can prematurely blind, causing issues like high-pressure drops, increased filter expenses, additional labor, decreased headroom for indoor applications, and enlarged filter housing.

- Online filter cleaning using the same primary system that the CMAXX uses, ensuring consistent cleaning of the filters during operation

- Compatibility with inline HEPA filters or a remote HEPA filter system as required, unlike other systems which require such filters to be mounted on top of the collector, limiting its flexibility.

The combined features of the CMAXX and IDA DeltaMAXX filters offer metalworkers and manufacturers the quality, safety, and value that we are dedicated to providing here at Imperial Systems.

Of course, it’s no surprise that together our products demonstrate some of the highest performance on the market, especially when you consider the impressive advantages each has to offer on its own. For over a decade, Imperial Systems has offered manufacturers and metalworkers like you advanced, reliable dust and fume collection equipment. Just check out the numbers– they speak for themselves!

CMAXX Dust Collector Advantages

|

DeltaMAXX Cartridge Filter Advantages

DeltaMAXX cartridge filters are made to fit all makes and models of cartridge dust collection systems |

All of our products also come with the Imperial Systems’ guarantee of outstanding customer service. We are dedicated to engineering and providing the solutions that manufacturers can rely on for the highest levels of quality, safety, and value. Whether you talk with our sales engineers or our field crews, we are confident that you will be impressed by our dedication to your service and safety.

If you would like to learn more about any of our products and how they may be able to improve safety and reduce costs in your workplace, please contact us today! You can reach us at 800.918.3913.

We Want To Hear From You

The particular needs and safety strategies for dust and fume combustion will vary from one workshop to the next. So, we want to hear from you! What challenges does your business face when it comes to handling combustible dust and fumes? What are you currently doing to control the risks? What solutions are you still looking for?

Let us know in the comments section below; we can’t wait to hear from you!