GOOD LUCK WITH THAT – New Beginnings

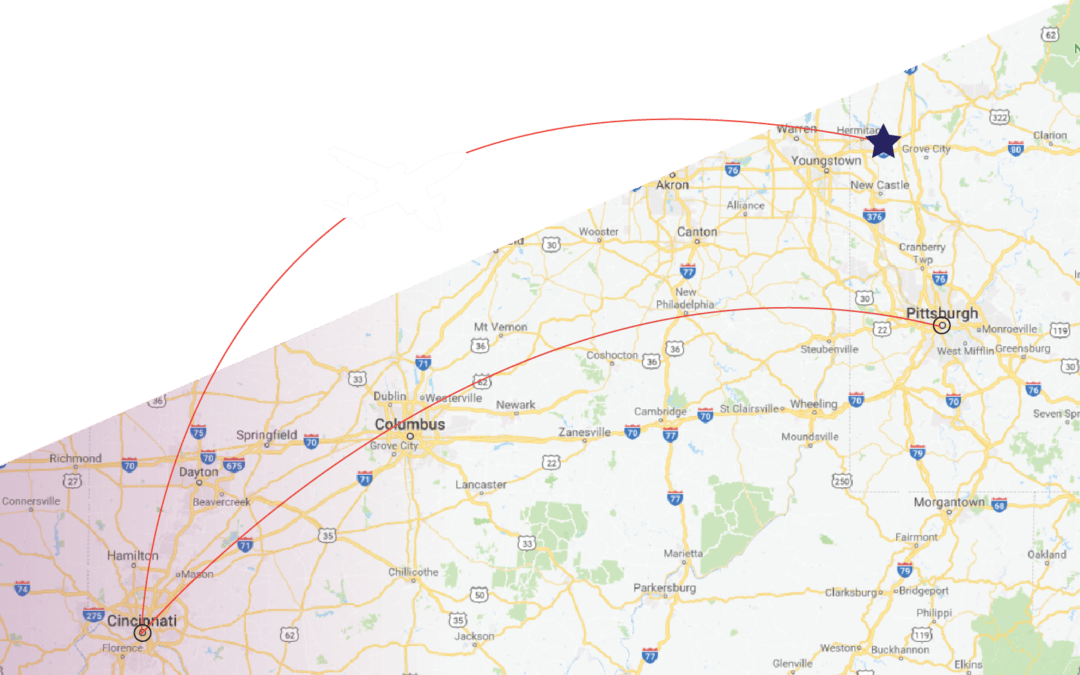

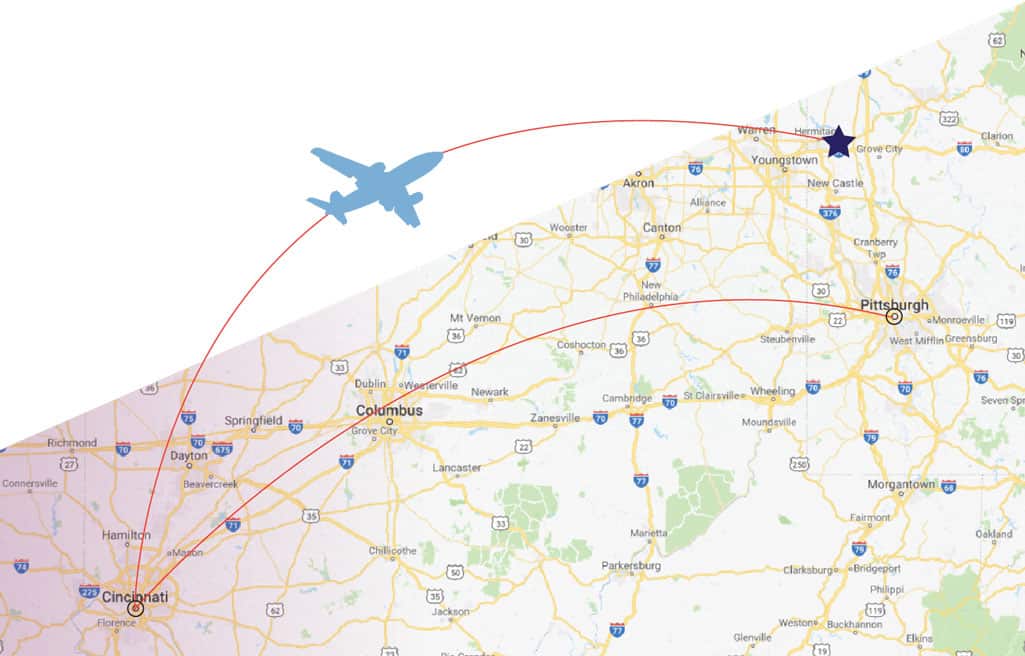

I began my professional journey in 1970, and over the past 48 years I’ve seen some changes. I’ve worked for three different companies over that time and have moved around a lot. I grew up in the Pittsburgh area. Right out of high school I began working for a century old, global company that was headquartered in Pittsburgh. They had several fabrication plants around the US and sales offices in England, Italy, Canada, Mexico, South Africa, and Brazil. I thought I struck gold to work for such a large, well established company. But when they hired me they had a different plan for me. They sent me to their relatively small, Air Systems Division, located in Cincinnati, Ohio. My first “New Beginning” uprooted me from my family, friends, and everything familiar, and moved me 300 miles away. This was a daunting experience for a 19-year-old. But my first employer was very good to me. They must have seen some potential because they encouraged me to continue my education under their tuition reimbursement program. So, I enrolled at the University of Cincinnati and eventually earned a B.S. degree (that’s Bachelor of Science, not the other BS). I spent most of my time with my first employer in Cincinnati, but moved back to Pittsburgh to work a few years for them there before moving again back to the Cincinnati plant. Unfortunately, even the largest and oldest companies can fail. After 9 ½, years I was let go along with many other employees company wide. Today, even though I see their building products everywhere, the company name has become almost nonexistent and their manufacturing plants have all been sold, shut down, or demolished. Today the trade name is owned by some Pacific Rim entity and that is about all that remains of them.

In 1981, I had another “New Beginning” with a Cincinnati based family owned company. I decided that a family owned business offered more security which was the most important aspect to me at the time. I now had a wife and two small daughters to support. My second employer was also good to me. They continued paying my college tuition until I graduated. If I got A’s, they paid 100% of all my college related expenses. That may be the main reason I have a special gold seal on my diploma that is embossed Summa Cum Laude. My second employer was also a very large company with manufacturing plants in 6 different states. They had annual sales in excess 100 million dollars, and at one time they were ranked the 3rd largest specialty sheet metal contactor in the United States. Everything was going great. I was taken out of engineering and promoted into engineering sales. I was placed under the guidance of a senior sales engineer and began making sales calls with him. As that was happening I didn’t realize I was being trained as his replacement. That gentleman retired a short time later and I was thrust into the world of engineering sales and yet another “New Beginning”. My second employer believed in moving us a lot by playing musical offices every few years. I believe they thought moving us around made us more productive. I was moved from offices on the first floor, to the basement, back to the first floor, up to the second floor, and so on. I worked for them for 29 years, so we moved around a lot. Alas, even large family owned companies have major changes. They were a third-generation company and over 100 years old. It was never destined to see a 4th generation of ownership, and the family sold the company to a publicly traded corporation. The change was not immediately apparent, but I soon came to realize I was not going to like working for a company listed on the stock exchange again. The “family feel” was gone and making money for the stock holders became the driving goal of the company. Since the family no longer owned the company, all my loyalties I felt were gone.

My last “New Beginning” began in 2010. I was out on a sales call, and when I returned to the office our receptionist handed me a phone memo that said Jeremiah Wong, of Imperial Systems, wanted me to return his call. I didn’t know any Amish-Oriental guys with an Asian trading company, so I called to see what he wanted. I found out that “Jeremiah Wann” was not Amish, or Oriental, and he had an offer for me. He wanted me to work for him. At first, I was skeptical. After all, I was now 59 years old and contemplating early retirement. Things were not going in any direction I cared for with my second employer. And there were my two daughters to consider. Although they were now grown young women and both employed, they still lived with me. But Jeremiah assured me my age was not an issue, and my daughters encouraged me to go for it. So, I took the next step. I pulled a Dunn and Bradstreet report on Imperial Systems. I found them to be a small, family owned business with a good credit rating. They paid their bills. That was important to me. I agreed to meet with Jeremiah to discuss details. Shortly after that, we came to an agreement. I again relocated 300 miles back to Pennsylvania, not too far from my birth city of Pittsburgh, and I found a home with Imperial. We are a small but growing company. Much different from the previous two larger companies I’ve worked for. Over my short seven years with Imperial Systems, I’ve seen two plant expansions. Our newest “New Beginning” is the beautiful new fabrication complex we moved into in January 2018. We now have better manufacturing capabilities and lots of space for expansion. We needed it. We are growing fast. I just turned 66 and obviously no longer contemplating early retirement. I’m thinking about hanging around for a few more years. A family will do that to you. But if you think I’m ready for any more “New Beginnings”, well good luck with that!

Read more