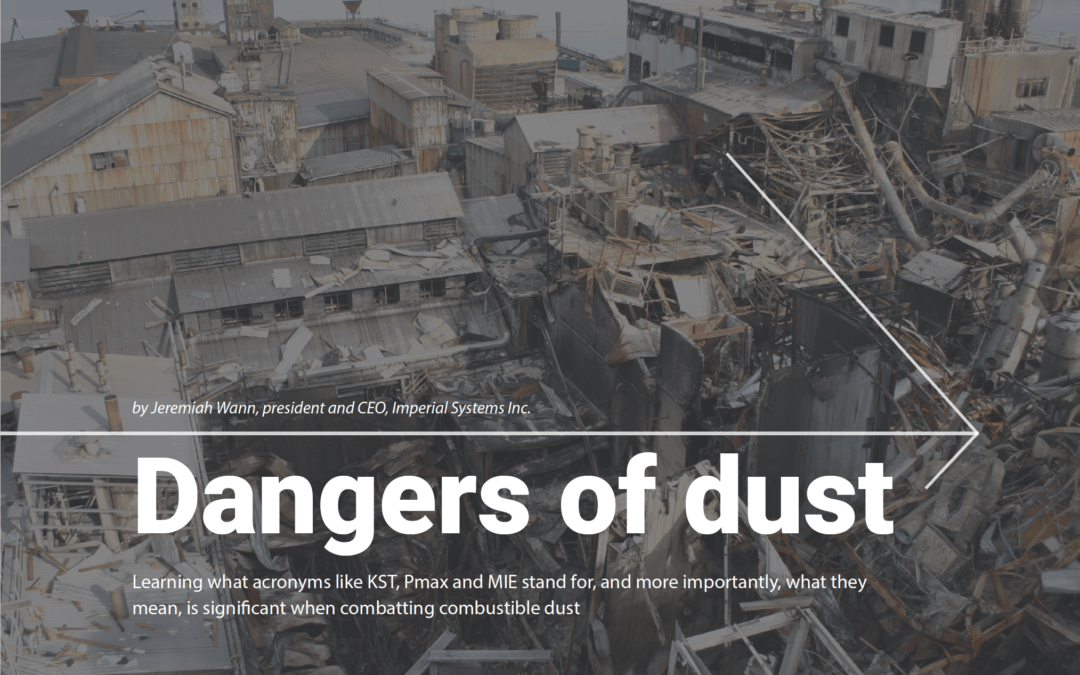

![Plasma Cutting & Hexavalent Chromium [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2018/12/white-paper-header-01-1080x675.jpg)

by Erin Long | Dec 19, 2018 | Uncategorized

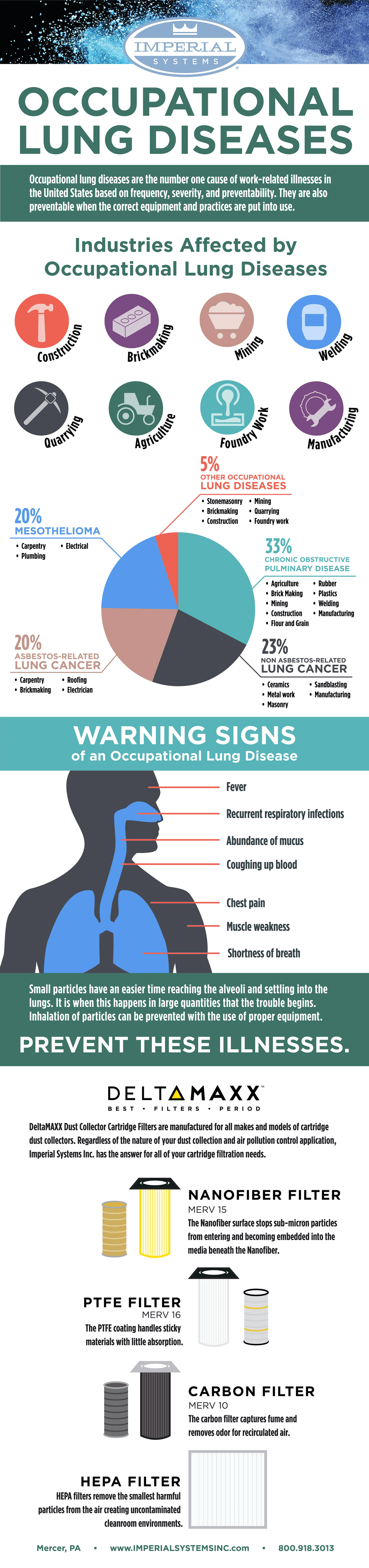

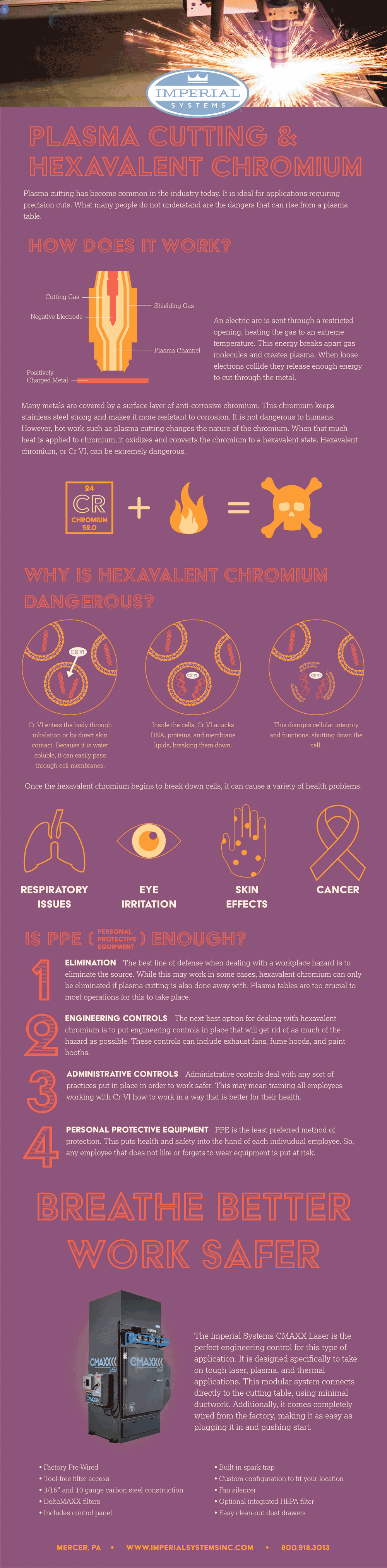

This infographic looks at the hidden dangers of plasma cutting and laser cutting. One of the biggest dangers associated with these is hexavalent chromium when cutting stainless steel. It can pose many health risks and proper precautions should be taken to avoid the risks associated with it.

Plasma cutting has become common in the industry today. It is ideal for applications requiring precision cuts. What many people do not understand are the dangers that can arise from a plasma table.

How Does It Work?

An electric arc is sent through a restricted opening, heating the gas to an extreme temperature. This energy breaks apart gas molecules and creates plasma. When loose electrons collide they release enough energy to cut through the metal. See more info on basic plasma cutting.

A surface layer of anti-corrosive chromium covers many metals. This chromium keeps stainless steel strong and makes it more resistant to corrosion. It is not dangerous to humans. However, hot work such as plasma cutting changes the nature of chromium. When that much heat is applied to chromium, it oxidizes and converts the chromium to a hexavalent state. Hexavalent chromium, or Cr VI, can be extremely dangerous.

Why Is Hexavalent Chromium Dangerous?

Cr VI enters the body through inhalation or direct skin contact. Because it is water-soluble, it can easily pass through cell membranes. Inside the cells, Cr VI attacks DNA, proteins, and membrane lipids, breaking them down. This disrupts cellular integrity and functions, shutting down the cell.

Once the hexavalent chromium begins to break down cells, it can cause various health problems. This includes respiratory issues, eye irritation, skin effects, and even cancer.

Is PPE Enough Protection from Hexavalent Chromium?

Elimination – The best line of defense when dealing with a workplace hazard is to eliminate the source. While this may work in some cases, hexavalent chromium can only be eliminated if plasma cutting is also done away with. Plasma tables are too crucial to most operations for this to take place.

Engineering Controls – The next best option for dealing with hexavalent chromium is to put engineering controls in place that will get rid of as much of the hazard as possible. These controls can include exhaust fans, fume hoods, and paint booths.

Administrative Controls – Administrative controls deal with any practices put in place to work safer. This may mean training all employees working with Cr VI how to work in a way that is better for their health.

Personal Protective Equipment – PPE is the least preferred method of protection. This puts health and safety into the hands of individual employees. So, any employee that does not like or forgets to wear equipment is put at risk.

Breathe Better, Work Safer

The Imperial Systems CMAXX Laser is the perfect engineering control for this type of application. It is designed specifically to take on tough laser, plasma, and thermal applications. This modular system connects directly to the cutting table, using minimal ductwork. Additionally, it comes completely wired from the factory, making it as easy as plugging it in and pushing Start.

Features:

- Factory pre-wired

- Tool-free filter access

- 3/16” and 10 gauge carbon steel construction

- DeltaMAXX filters

- Includes control panel

- Built-in spark trap

- Custom configuration to fit your location

- Fan silencer

- Optional integrated HEPA filter

- Easy clean-out dust drawers

Read more about this issue and about how the CMAXX Laser can help you in the white paper.

Read more

by Scott Stearns | Nov 26, 2018 | Uncategorized

Dusty Jobs Issue 7 is the third quarter of the year. Check out the articles! Charlie is back with an article about food, and we interview one of our welders, Richard Matters. If you would like a printed hard copy of this issue of the quarterly newsletter, contact your Imperial System Sales Rep.

Click the cover to download and print the newsletter.

CLICK THE ARTICLE TO READ.

Read more

by Scott Stearns | Nov 26, 2018 | Hidden from Archive

Richard has been welding at Imperial Systems for twelve years, and in various other jobs for eighteen years before that. He is a graduate of Jamestown High School. Outside of work he enjoys relaxing with his wife and spending time with his three kids and eight grandkids.

Q: What date did you start working at Imperial Systems?

Q: What date did you start working at Imperial Systems?

A: September 17, 2006

You said it was only that first bay?

A: Yeah. It was probably ten or so guys working. The road crew was there.

Q: That would be pretty tight.

A: Yeah it was for everything we build, like us with the big BRFs. You see how much room the fourteen footers take up here. It was tight, but we did it.

Q: How long have you been welding?

A: Oh jeez. Twenty-five or thirty years. I had thirteen years in at Trinity Industries, twelve here, and five at Tri‑County. I was welding dumpsters and stuff, rebuilding them. Then I worked a couple other places. There was a rail division down in New Castle. I didn’t work there very long because it was too far of a drive from my house. It was an hour and a half each way.

Q: Did you go to trade school?

A: No. When Trinity shut down we did get to go to school. You could keep your unemployment because they moved out of the country and went to Mexico. So they put up a school and you could draw your unemployment while you were in school. Even when I started at Trinity they put me through weld school at Mercer Vo-Tech. It wasn’t a long class, thirty days or something like that. It was heavier. Rail cars. It was big.

Q: How many kids do you have?

A: Three. Two girls and a boy. I’ve got eight grandkids. Two are twin boys.

Q: Do you like any sports?

A: I watch a lot of football. I’m a big Steelers fan.

Q: You got that question correct.

A: I’m a little unhappy with them right now.

Q: What do you do for fun?

A: We usually sit down back. We built a big pavilion and we usually sit down there, me and the wife, drink beer and listen to the radio, build a fire.

Q: What kind of music do you like?

Q: What kind of music do you like?

A: Country. Willie 95. They’ve changed country so much. Its more getting into pop or something.

Q: Do you ever go to concerts?

A: Nah. Once I went up to Crawford County and George Jones was there. It was a pretty good concert. Loretta Lynn was there too that night, but she wasn’t feeling good. She had laryngitis and was having trouble singing.

Q: Do you have any projects at home that you do?

A: All the time. It seems like the wife always has something for me to do!

Q: You ever go to any football games or anything?

A: No, I always wanted to, but usually I say “Why would I want to go watch that live when I could sit at home and watch it with no crowd?” And usually its too cold, too. I don’t want to be out there in the freezing weather. Then, when you drink like I do you can’t afford to go there with the price of their beer, jeez.

Q: You’re just a good country guy, huh?

A: That’s pretty much it. I don’t bother no one, no one bothers me. That’s what I like. We have a lot of parties though. We have a big Fourth of July party every year. We’ve been doing that for about twenty years now. We invite a bunch of people and get fireworks. Seems like it keeps getting bigger every year. More and more people come, and more fireworks we have to buy. But its fun. We have a lot of fun. We’re out in the country enough that no one bothers you either, thats whats nice.

Q: What do you think about being in the magazine?

A: It’s good. It gets it out.

Q: We’re showing off our employees. We’re proud of you guys. We want you to be known for the work you’ve done. It’s because of you guys that this place…

A: It goes! And that’s good. We need it to keep going for a long time, hopefully.

Q: Do you have anything else you want to say?

A: I do appreciate having the opportunity to work here. I appreciate that. And Jeremiah’s real fair about everything, as far as I’m concerned. He’s a good guy, and good to his people too. There ain’t too many places where on holidays you leave early and they pay you for the rest of the day and stuff like that. I’ve never heard of any companies doing that, not that I worked for.

Read more

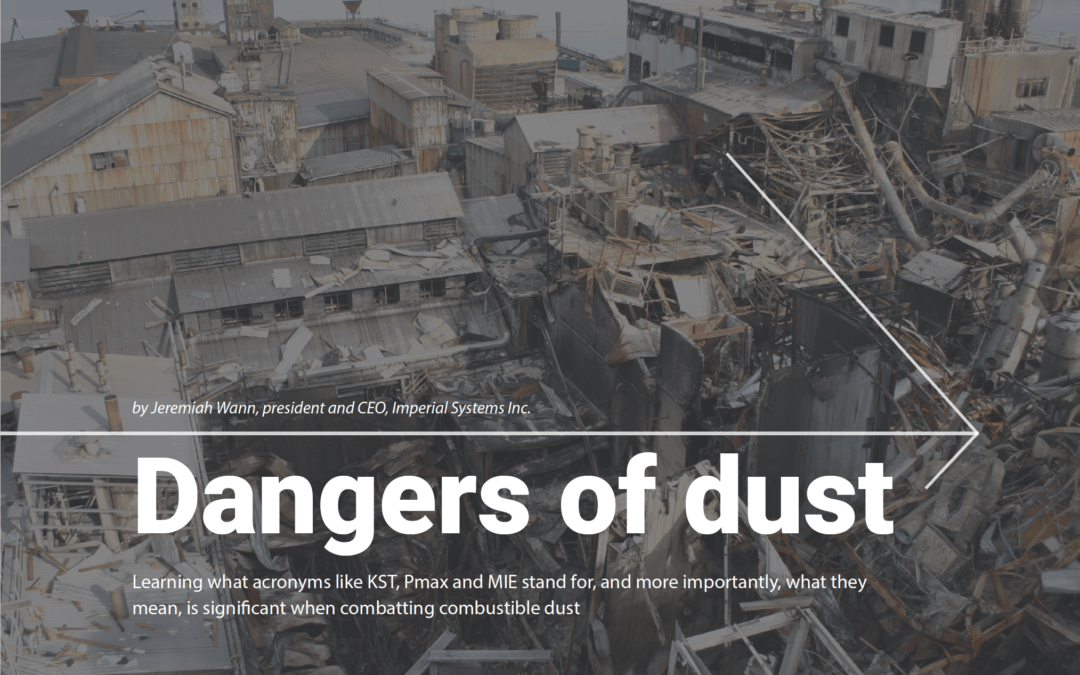

by Scott Stearns | Aug 22, 2018 | Uncategorized

There are many things that can affect the hazard that your combustible dust presents. It’s possible for dust that is very safe under most circumstances to cause a dangerous explosion if something goes wrong. Here we’ll talk about some of the kinds of information that you may need to know about your dust to make sure you are protected.

Many engineers will recommend that you test your dust professionally before finalizing your system design. There are a variety of companies that do this; check with your systems engineer to find out who they prefer to work with. This will require you to send in a sample of your dust. If you have more than one type of dust (for example, fine dust from welding and heavier rough dust from grinding), you will want to send samples of all of them to make sure your system can be designed for maximum safety. Combustible dust explosions kill people every year and cause massive damage to property, and it’s worth controlling the problem safely in your facility.

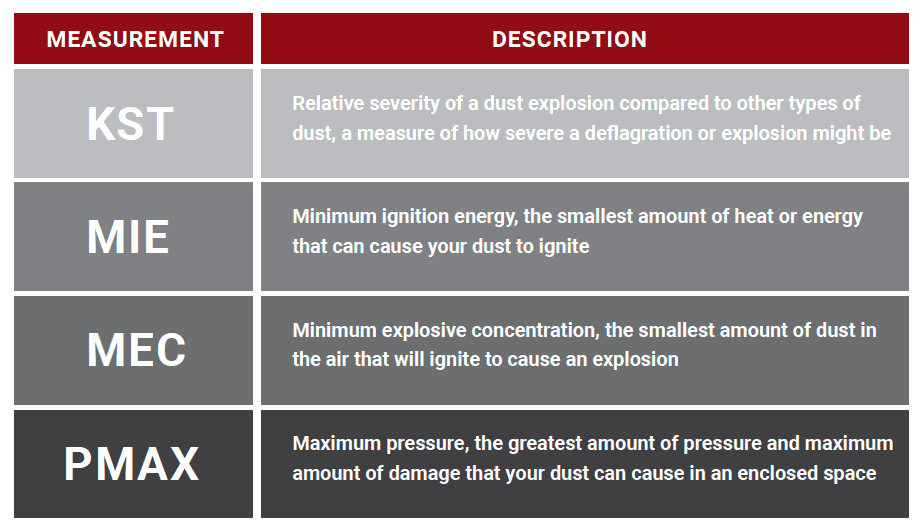

Dust Test Measurements

PARTICLE SIZE (microns):

Some materials are very inert as large pieces, but will burn rapidly in small particulate. Particle size measurement is usually in microns. This is also important for filter efficiency. Particle size is also very important for health purposes: larger particles may be trapped in the nose and throat where they are easy for the body to get rid of, while fine particles (under 30 microns) travel deep into the lungs.

MINIMUM IGNITION ENERGY (MIE):

This is a measurement of how much energy your dust requires to ignite. Some dust requires a lot of energy to ignite (in some explosions, the source of ignition has been an overheating bearing or an open flame). Other dust can ignite with much less energy. Static charges can ignite many types of dust. MIE is how much energy the dust needs to make it ignite.

MINIMUM EXPLOSIVE CONCENTRATION (MEC):

This measures how much dust must be present to cause an explosion. This measurement is usually with airborne dust. It tells you how much dust in the air will ignite if there is a heat source around. This is important because it explains how much dust needs to be floating around in the air to cause an explosion. A secondary explosion, which happens when dust that accumulates in the area lofts into the air by the first explosion, can involve a lot more dust and be a lot more dangerous.

MINIMUM AND MAXIMUM EXPLOSION PRESSURE (PMINand PMAX):

The minimum and maximum explosion pressure. Personnel conduct tests on dust inside a container that can measure pressure. Pminis the smallest amount of pressure that ignition of the dust can produce. Then there’s Pmax, which is more important. It is the maximum amount of pressure that explosive ignition can produce.

Pmax is measured by increasing the concentration of dust inside the closed chamber and measuring the pressure of the explosion until the maximum is reached (until the greatest possible amount of damage has been determined). This is an important calculation because it allows you to calculate how much damage your dust is capable of doing inside a closed container (like ductwork or a dust collector).

MAXIMUM RATE OF PRESSURE RISE/DEFLAGRATION INDEX ( KST):

MAXIMUM RATE OF PRESSURE RISE/DEFLAGRATION INDEX ( KST):

This measurement is done in a similar way to Pmax. A mathematical formula converts Pmax to KST, taking the volume (size of the chamber) out of the measurement.

KST is an extremely important test! The Pmaxmeasures the maximum pressure that the dust could exert exploding in a closed space, but KST is a general measurement of explosiveness. It is a standard measurement for dust collection system design purposes.

The Importance of KST

KST is a measurement of explosion pressure, NOT of combustibility. A low KST does NOT mean that your dust cannot burn and cause catastrophic damage. KST only tells you how strong the potential explosive force, not how flammable the dust is.

A KST of 0 means that dust is not combustible; its Pmin and Pmax are 0 and in a testing chamber it cannot produce any explosion.

A KST of greater than 0 means the dust is combustible; testing Pmax can create an explosion in the testing chamber. From 0 to 200 (which includes many metal dusts) the explosion class is 1; a weak explosion. NOTE: a “weak explosion” does not mean “no damage”! The catastrophic Imperial Sugar explosion that destroyed a building and killed over a dozen people was caused by sugar with a KST of 1.

A KST from 200 to 300 is a strong explosion (Class 2), and could include things like cellulose dust, other organic fine dust, and some metals and plastics.

A KST over 300 is a very strong explosion (Class 3). Aluminum and magnesium dust are in this category.

Any dust with any Kst above zero is potentially combustible and can cause an explosion. Your system will require appropriate fire and explosion prevention. Fire prevention is key to keep ignition sources out of the dust collector, including spark traps, abort gates, and water or chemical suppression systems. Explosion vent panels are also critical to make sure that an explosion does not cause serious damage if it does occur.

Dust Testing: Putting the Pieces Together

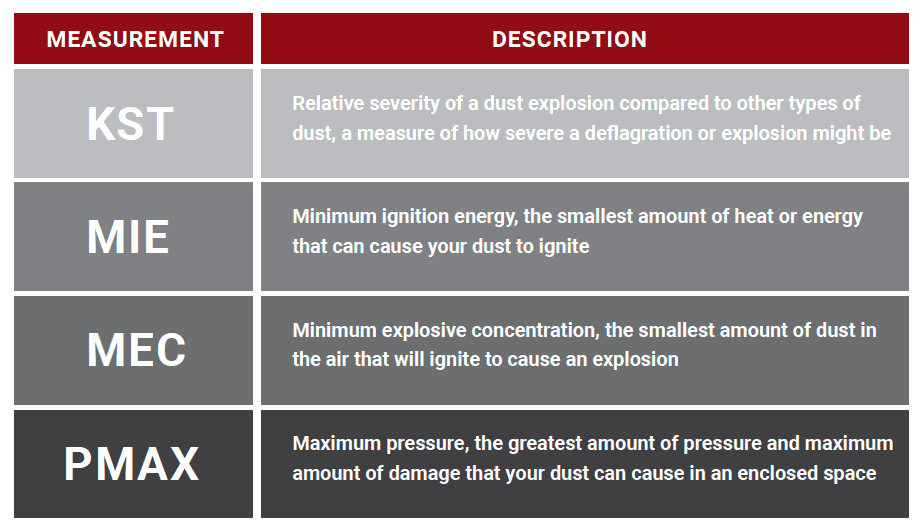

As you can see, all of these pieces of information are important when testing your dust.

– The KST (which is calculated from PMax) tells you how strong an explosion is likely to be.

– The size of the dust is important in determining whether it is combustible.

– The MIE tells you how much or how little energy it will take to ignite your dust

– The MEC tells you how much dust in the air will risk an explosion

A dust with a low KST (sugar, as an example, but also many metals) has a low but not zero KST. It is not going to cause a strong explosion. However, in one facility that had a lot of accumulated sugar dust, an overheating piece of equipment exceeded the dust’s MIE value and ignited it. With so much sugar in the air, the MEC was also exceeded and the dust in the air ignited explosively.

To review: in this instance, a dust with a LOW KST (sugar) was in contact with a heat source that exceeded the MIE and ignited the dust. Because there was a large amount of dust in the air, the MEC was too high and the dust exploded. Secondary explosions caused even more damage because the explosions blew dust into the air and raised the MEC even more. For more information on this incident, see the Chemical Safety Board’s report of the Imperial Sugar Explosions.

While this explosion did not have a high pressure, it did create multiple large low-pressure explosions that blew apart the building and caused numerous deaths. A low KST does not mean your facility is safe from combustible dust explosions.

Table 1: Key Terms and Definitions

OSHA on Combustible Dust

Article featured in the July/August Issue of Shop Floor Lasers. Go here to see the digital issue. SHOP FLOOR LASERS

Read our white paper on combustible dust.

Read more

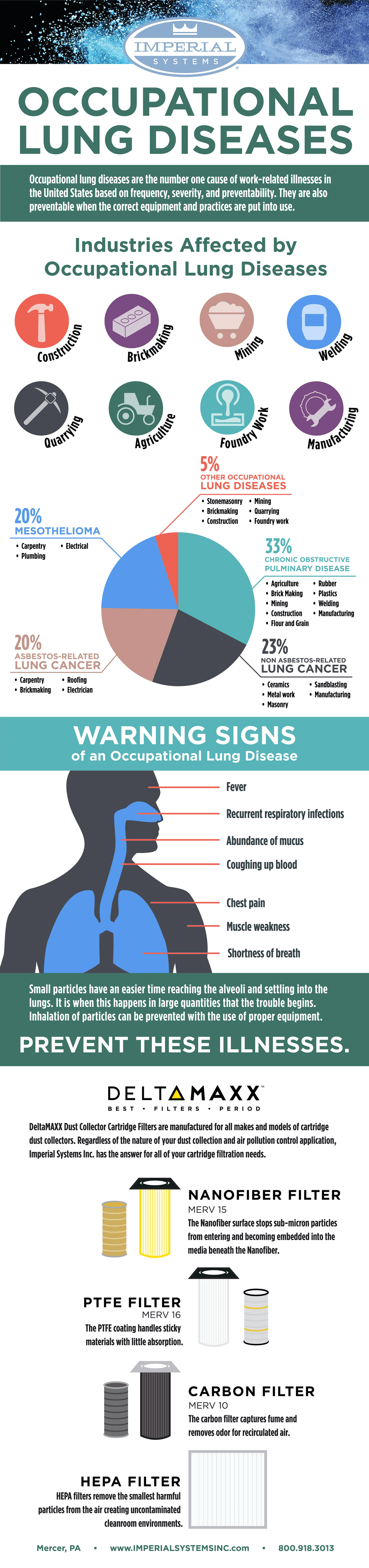

![Occupational Lung Diseases From Dust & Fumes [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2018/08/health-risk-infographic1-1080x675.jpg)

by Scott Stearns | Aug 14, 2018 | Uncategorized

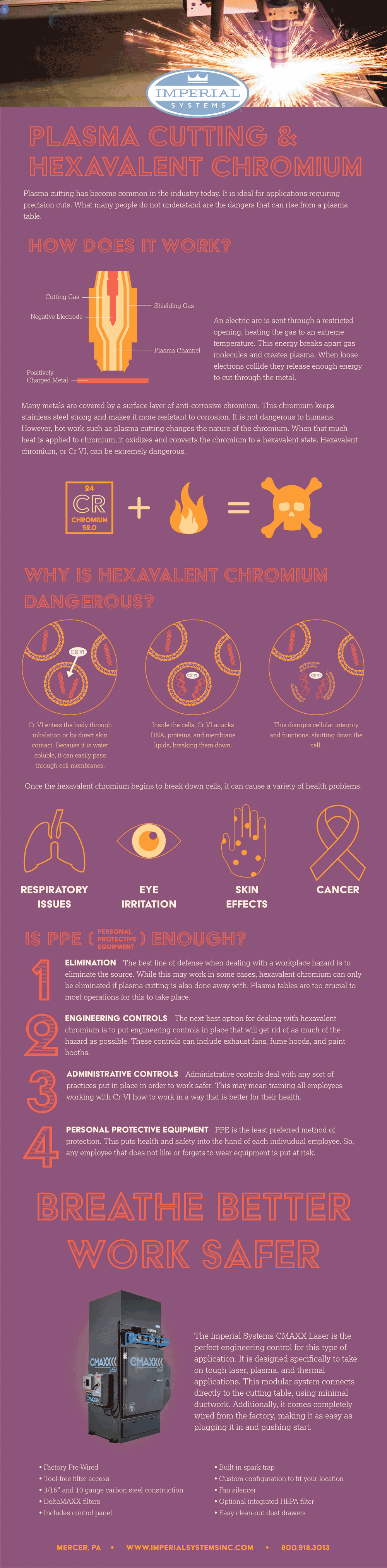

Industries Affected by Occupational Lung Diseases

There are many trades and business operations associated with respiratory illnesses. For example, construction workers are a high-risk group for occupational lung diseases, a study by the National Library of Medicine concluded. There is exposure to high concentrations of dusts in closed spaces and they breathe high levels of crystalline silica. Inhaling free crystalline silica causes a lung disease named Silicosis. Processes like brickmaking, quarrying, and foundry work for making building materials are also high risk to workers. Lung function impairment is the most common respiratory problem among workers with exposure to dusts.

Occupational lung diseases also affect the mining, agriculture, and manufacturing industries. Johns Hopkins Medicine reports that crystalline silica is found in the air of mines, foundries, blasting operations, and stone, clay, and glass manufacturing facilities. Further, people at higher risk for occupational asthma often work in manufacturing and processing operations, farming, animal care, food processing, cotton and textile industries, and refining operations.

Warning Signs and Best Prevention

Common symptoms include fever, recurrent respiratory infections, an abundance of mucus, coughing up blood, chest pain, muscle weakness, and shortness of breath. However, occupational lung diseases can be prevented. Avoiding the inhalation of dust and fumes that cause lung diseases is the best thing you can do. Small particles have an easier time reaching the alveoli and settling into the lungs. Trouble begins when this happens in large quantities.

The infographic below illustrates the lung diseases found in various industries and denotes their warning signs in the body. It also presents how an Imperial Systems CMAXX dust and fume collector with DeltaMAXX filters can help save your life.

Contact Imperial Systems today for a review of your dust and fume collection challenges. We will design a system to help keep your employees safe from occupational lung diseases.

Read more

![Plasma Cutting & Hexavalent Chromium [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2018/12/white-paper-header-01-1080x675.jpg)

Q: What date did you start working at

Q: What date did you start working at Q: What kind of music do you like?

Q: What kind of music do you like?

![Occupational Lung Diseases From Dust & Fumes [Infographic]](https://www.isystemsweb.com/wp-content/uploads/2018/08/health-risk-infographic1-1080x675.jpg)