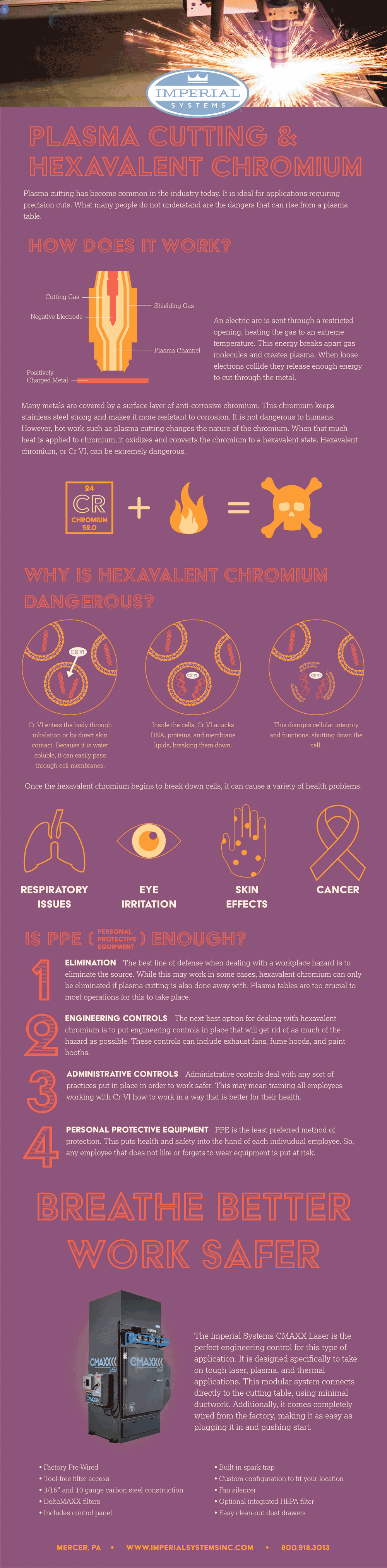

This infographic looks at the hidden dangers of plasma cutting and laser cutting. One of the biggest dangers associated with these is hexavalent chromium when cutting stainless steel. It can pose many health risks and proper precautions should be taken to avoid the risks associated with it.

Plasma cutting has become common in the industry today. It is ideal for applications requiring precision cuts. What many people do not understand are the dangers that can arise from a plasma table.

How Does It Work?

An electric arc is sent through a restricted opening, heating the gas to an extreme temperature. This energy breaks apart gas molecules and creates plasma. When loose electrons collide they release enough energy to cut through the metal. See more info on basic plasma cutting.

A surface layer of anti-corrosive chromium covers many metals. This chromium keeps stainless steel strong and makes it more resistant to corrosion. It is not dangerous to humans. However, hot work such as plasma cutting changes the nature of chromium. When that much heat is applied to chromium, it oxidizes and converts the chromium to a hexavalent state. Hexavalent chromium, or Cr VI, can be extremely dangerous.

Why Is Hexavalent Chromium Dangerous?

Cr VI enters the body through inhalation or direct skin contact. Because it is water-soluble, it can easily pass through cell membranes. Inside the cells, Cr VI attacks DNA, proteins, and membrane lipids, breaking them down. This disrupts cellular integrity and functions, shutting down the cell.

Once the hexavalent chromium begins to break down cells, it can cause various health problems. This includes respiratory issues, eye irritation, skin effects, and even cancer.

Is PPE Enough Protection from Hexavalent Chromium?

Elimination – The best line of defense when dealing with a workplace hazard is to eliminate the source. While this may work in some cases, hexavalent chromium can only be eliminated if plasma cutting is also done away with. Plasma tables are too crucial to most operations for this to take place.

Engineering Controls – The next best option for dealing with hexavalent chromium is to put engineering controls in place that will get rid of as much of the hazard as possible. These controls can include exhaust fans, fume hoods, and paint booths.

Administrative Controls – Administrative controls deal with any practices put in place to work safer. This may mean training all employees working with Cr VI how to work in a way that is better for their health.

Personal Protective Equipment – PPE is the least preferred method of protection. This puts health and safety into the hands of individual employees. So, any employee that does not like or forgets to wear equipment is put at risk.

Breathe Better, Work Safer

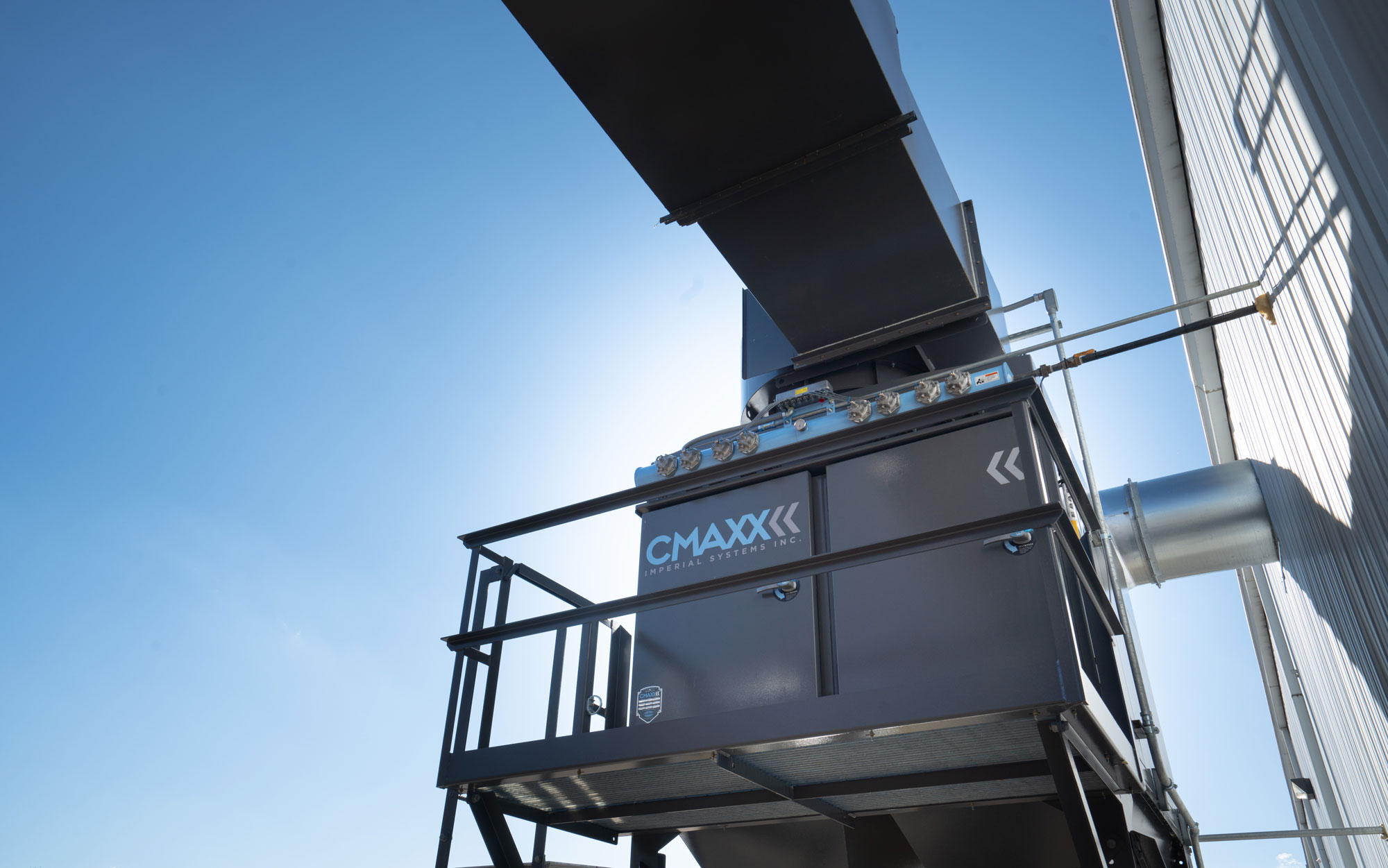

The Imperial Systems CMAXX Laser is the perfect engineering control for this type of application. It is designed specifically to take on tough laser, plasma, and thermal applications. This modular system connects directly to the cutting table, using minimal ductwork. Additionally, it comes completely wired from the factory, making it as easy as plugging it in and pushing Start.

Features:

- Factory pre-wired

- Tool-free filter access

- 3/16” and 10 gauge carbon steel construction

- DeltaMAXX filters

- Includes control panel

- Built-in spark trap

- Custom configuration to fit your location

- Fan silencer

- Optional integrated HEPA filter

- Easy clean-out dust drawers

Read more about this issue and about how the CMAXX Laser can help you in the white paper.