Cartridge filter replacement is an essential part of preventing accidents in your manufacturing plant.

Cartridge filter replacement is an important step in eliminating potential causes of ignition if you are in metalworking, manufacturing, or woodwork.

What are cartridge filters?

What are cartridge filters?

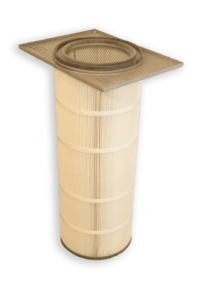

Cartridge filters are applied in a variety of contexts as a tool to filter water, chemicals, hydraulic fluid, and other types. They include the media for filtration, the receptacle, and the liquid filter. Since cartridges are porous, they can be made from many types of media such as carbon, polythermoplastics, metal mesh, nylon, and even paper.

If you require a cartridge filter replacement that will filter media of large sizes, this type will have a faster rate of flow than those that filter only small impurities. Filters’ very disposability is one of their benefits in metalworking and other industrial manufacturing. They can be removed with ease and replaced with an exact replica.

For this reason, a disposable cartridge filter replacement will come to you pre-filled with the required filter media and have a set duration. Then the cartridge should be thrown away and replaced with a new cartridge. There are also refillable cartridges which can be re-used a number of times. In the case of refillable cartridges, only the filter media needs to be replaced while the actual filter can be washed out.

Why it’s important

-

- 1. Safety

Everyone agrees that prevention is the key to ensuring that serious hazards are eliminated, but oftentimes, industrial dust collection may be a subject that just…slips through the cracks for many manufacturing managers. The dust collector or cartridge filter may not be used on a regular day-to-day basis by the person deciding when to have it checked or replaced, so the subject is easily forgotten or, relegated to the bottom of the priority list because it seems like an extra cost. But forgetting about dust collection until it is too late is not an option when the health and livelihood of your employees is at stake. As an employer, you can encounter serious problems with the law if you allow an accident of this sort to occur on your watch.

- 1. Safety

-

- 2. Equipment life

The life of your equipment, whether that’s a welding table, CNC cutting table, laser/plasma cutting table, etc., will be extended through your good care of it. Using proper filtration media in your industrial plant to ensure that all impurities are blocked during production will ensure longer life. Don’t forget to check your cartridge filter and research whether you are using the right type of media for your needs. You can talk to us at Imperial Systems at 724-662-2801 for advice pertaining to your particular industry.

- 2. Equipment life

- 3. Save Money

If ensuring proper filtration extends the life of your equipment, you can be sure that taking this step will also help save your company money in the long haul. If you bought a $60,000 car, you’d be sure to buy the correct parts and maintenance tools. Why not take care of your $60,000 machine that produces your revenue? A cartridge filter replacement is an investment that will help you avoid future costs and problems.

For more information on cartridge filter replacements, our professionals are glad to assist you with the needs pertaining to your particular industry and business. Visit the Imperial Systems website or call us at 724-662-2801 to get started.

Cartridge filter replacement | filter cartridges relevant