A career center in West Virginia needed efficient ventilation to create a weld school in their existing facility. While many companies had suggested installing snorkel arms, this would rely on students to move and properly use the arms. The school needed a better solution. They wanted to effectively remove weld fume without extra effort from the students or administration.

The Situation with Fumes in a Weld School

A school district in West Virginia was preparing to convert a childcare training area into a weld school. This was happening at their Career and Technical Center to fill the local demand for trained fabricators and welders. Imperial Systems’ territory manager Mitch Augustine was tapped by a sales partner in the weld gas supply industry to meet with the school’s team looking for ventilation systems.

A school district in West Virginia was preparing to convert a childcare training area into a weld school. This was happening at their Career and Technical Center to fill the local demand for trained fabricators and welders. Imperial Systems’ territory manager Mitch Augustine was tapped by a sales partner in the weld gas supply industry to meet with the school’s team looking for ventilation systems.

The Evaluation

During initial discussions, Mitch quickly identified the team’s desire to capture the smoke and fume effectively at the source. They intended on relying on the snorkel arms that Lincoln Electric, Miller Electric, and others had proposed. However, there’s an issue with using extraction arms. Because the effective capture area is limited, students must keep the arms in the capture zone. This creates a reliance on the students to consistently maneuver the flexible arms as they focus on their tasks. It was important for the administration to keep the space clean and clear of smoke and haze. But they didn’t want to rely on their instructor to “police” the students’ proper use of the extraction arms.

Mitch took this into consideration and suggested that the school consider weld fume hoods instead of fume arms. These hoods allow the students to focus on their tasks without the worry and burden of adjusting fume arms. Weld fume hoods are oftentimes the solution for a more immediate capture than an ambient collection system provides.

The Solution

The Solution

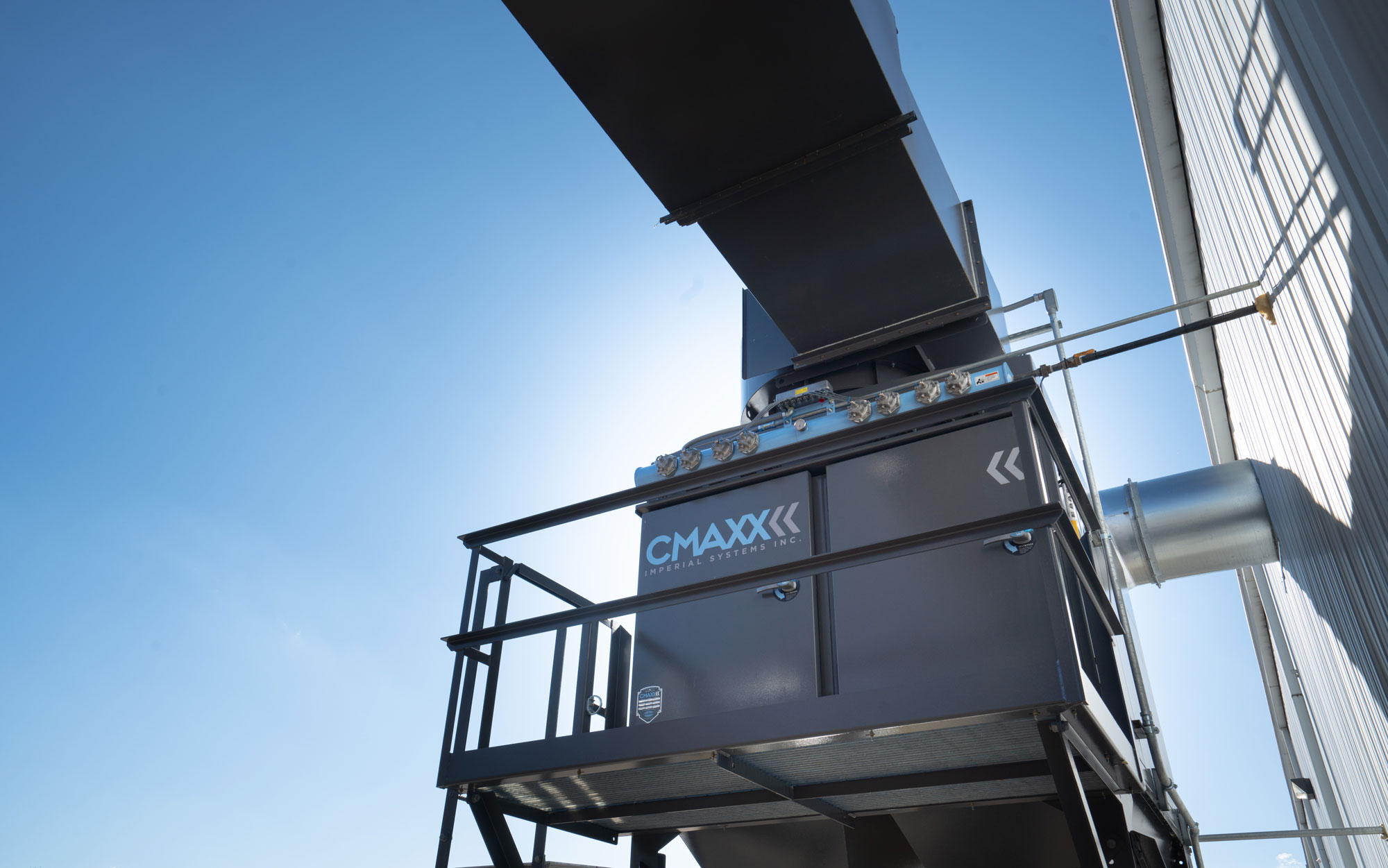

Imperial was awarded the project and fabricated custom hoods with LED lighting and offset overhead fume extraction. This keeps the smoke and fume out of the operator’s breathing zone. Most importantly, It requires no adjustments or action from either the student or instructor at the weld school. Ultimately, 24 hoods, a Spark Trap, and a 16-filter cartridge CMAXX Dust & Fume Collector were supplied. Professional installation was done by Imperial’s own OSHA-trained field crew. The Spark Trap ensures that any sparks collected by the hoods are eliminated before reaching the dust collector and filter media.

Weld School Success in Extracting Manual Weld Fume

After several months of active training in the weld school, the space remains clean and smoke-free. The instructor reported that the installed system is both effective and easy to use. “Simply turn the thing on when we get started and the room stays clear and smoke-free. This system is so much easier to use than any of the other portable-type units with the flex arms that I have always used in the past. I guess it is best to leave the fume extraction to the real experts and let the welding guys supply the welders!”