1. What do the different types of pressure measurements mean for airflow in ductwork?

- The basic behavior of airflow: it always travels through the past of least resistance, from higher pressures to lower pressures.

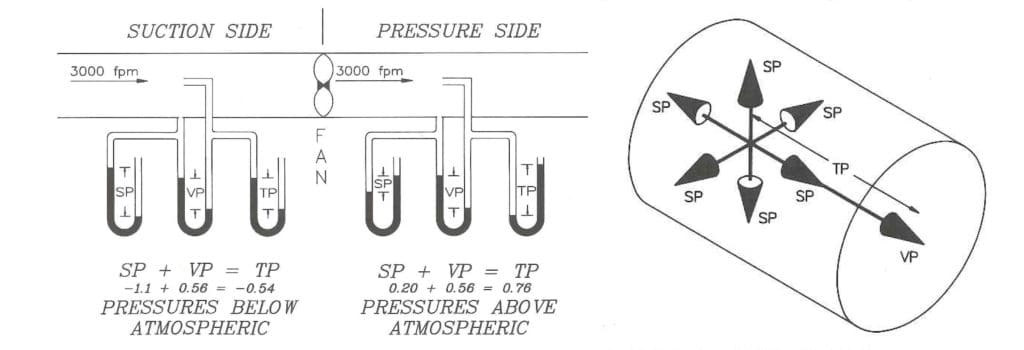

- STATIC PRESSURE: potential pressure exerted in all directions in the ductwork with no airflow, measured with a manometer. It can also be positive (pressure outward on the duct) or negative (pressure pulling inward on the duct)

- VELOCITY PRESSURE: pressure necessary to move air through the ductwork at a certain velocity. Further, this is kinetic energy, and the pressure is in the direction of the airflow.

- TOTAL PRESSURE: a calculation of system static pressure and velocity pressure (the formula is TP=SP+VP). It can be positive or negative. It is the overall energy content of the air stream.

2. When we do our airflow calculations to determine our fan size, what’s the difference between SCFM and ACFM?

- SCFM is Standard Cubic Feet per Minute. This is a measurement based on a standard temperature and air pressure.

- Temperature and air pressure can be significantly different in different areas (e.g. higher altitude, cold or hot climate, high humidity). Then can also vary in different applications (high/low temperature or humidity applications).

- ACFM is Actual Cubic Feet per Minute. This is a measurement of the actual airflow conditions that your system will be operating under.

- Fan manufacturers are able to make these airflow calculations. However, they need to be provided with accurate data about temperature and humidity conditions in your application.

3. What is conveying velocity and why is it important?

- The unit of measurement for conveying velocity is feet per minute (FPM). It is the required velocity to pick up dust in the air stream and move it through the ductwork.

- It is calculated by the CFM at the point of capture and the square foot cross-section of the ductwork.

- This is extremely important because if the conveying velocity drops too low at any point in the dust transport, the dust will drop out of the airflow.

- There are a variety of tables to help engineers calculate the minimum conveying velocity for different kinds of dust.

- Combustible materials might need a higher minimum conveying velocity. This is because an accumulation of this material in the ductwork could cause a deflagration or dust explosion.