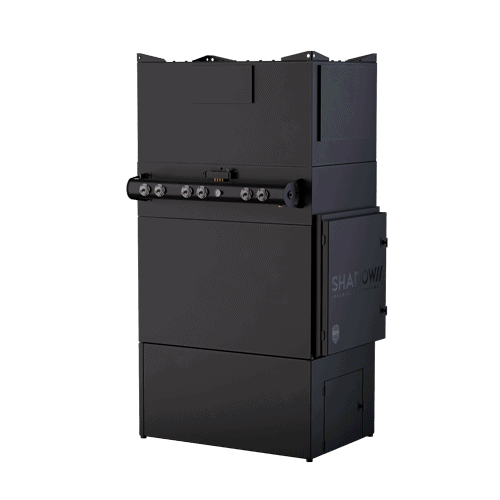

Shadow Compact Fume Extractor

Compact Footprint, Big Performance

The Shadow Compact Fume Extractor fills the need for a basic fume extractor system. It offers a cost effective option for managing manual weld fume, robotic weld fume, and laser cutting fume. The Shadow offers the same air quality control as a premium dust and fume extractor at a lower price point.

What makes the Shadow Compact Fume Extractor right for you?

- Compact footprint for easy placement in tight spaces

- Fully assembled housing for quick installation

- No costly explosion controls needed for non-combustible dusts

- Built for safe indoor operation

- Remote-start capable for simple, convenient monitoring

- Integrated HEPA filtration for superior air quality and fine particulate capture

Continuous Pulse Cleaning

A continuous pulse cleaning system removes dust buildup from the filters, keeping airflow consistent. This self-cleaning feature reduces maintenance needs and helps the fume extractor operate at peak efficiency for longer.

Accessible Collection Bucket

The easily accessible material collection bucket allows for quick and hassle-free emptying of captured dust and debris. It’s convenient design simplifies routine maintenance.

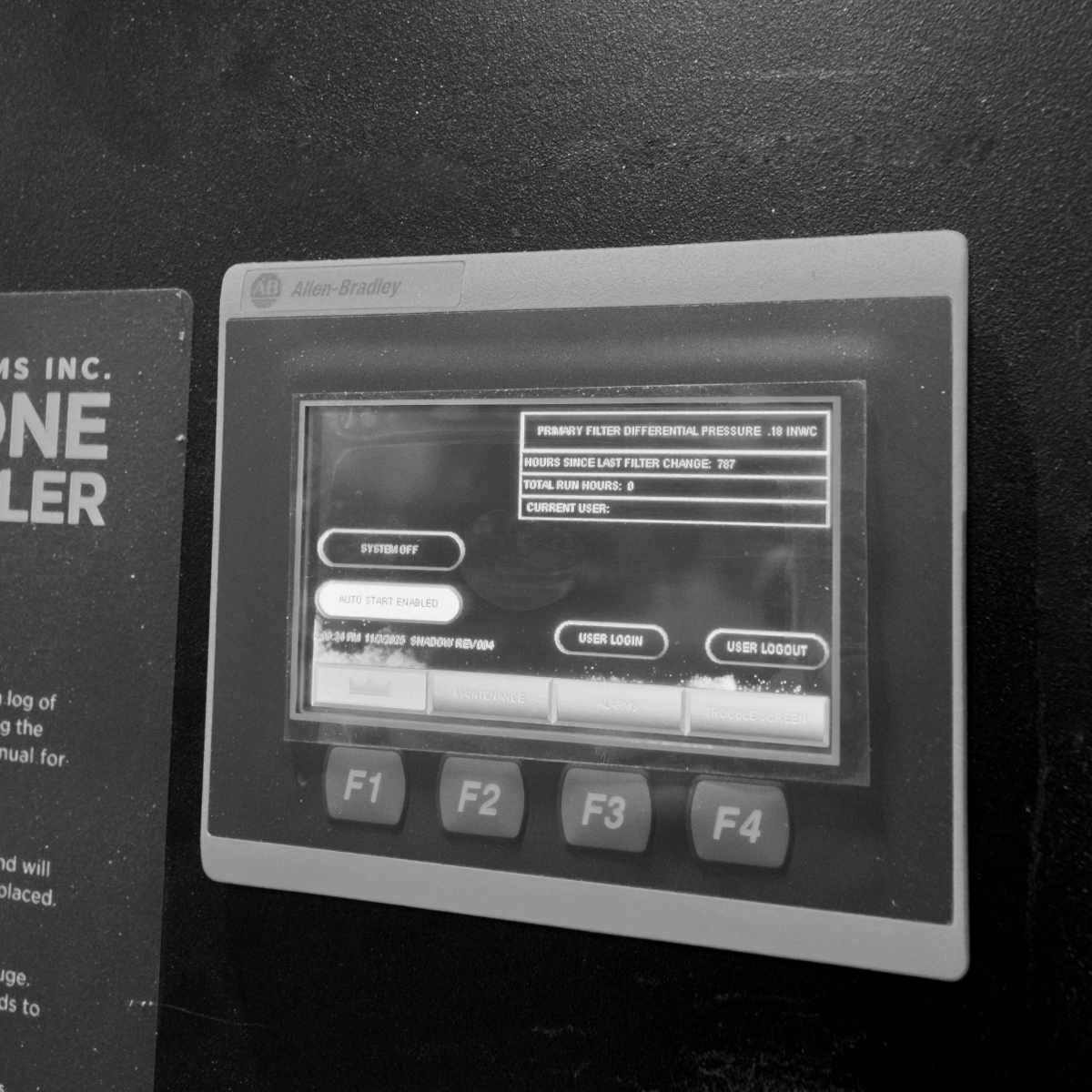

Differential Pressure Monitoring

Differential pressure monitoring continuously tracks filter performance, alerting you when cleaning or replacement is needed. This ensures optimal airflow and maintains the fume extractor’s efficiency at all times.

Optional Features for the Shadow Compact Fume Extractor

Sprinklers

The sprinkler head provides an added layer of fire protection for environments where sparks or hot particles are common. If a thermal event occurs, sprinklers help suppress flames quickly, reducing the risk of damage to the fume extractor or surrounding equipment.

Inlet & Outlet Dampers

Inlet and outlet dampers allow for precise control of airflow through the fume extractor. They help balance system performance and prevent backflow, maintaining consistent suction at the capture points. Adjusting dampers can also improve energy efficiency and reduce wear on the fan and filters.

Smoke Detector

An integrated smoke detector provides early warning if smoke is detected in the air stream or unit, enhancing safety in high-risk environments. It can trigger alarms or shut down the system automatically to prevent damage or escalation.

Multi-Directional Inlet

The Shadow’s inlet provides flexibility in ducting and connection orientation, allowing the unit to fit seamlessly into tight or complex shop layouts. It makes installation easier and reduces the need for additional ductwork modifications. This feature also supports multiple capture points or different equipment configurations.

Spark Resistant Inlet

A spark resistant inlet protects the fume extractor from potential damage caused by flying sparks or hot particulate. It helps prevent fires and prolongs the life of the unit. It is recommended for high sparking applications.

Sound Control Insulation

Sound control insulation reduces operational noise, creating a quieter work encironment. It is especially valuable in indoor installations where prolonged exposure to fan noise could affect worker comfort or communication. The insulation helps maintain productivity while keeping air extraction performance high.

Hover or tap the letters to learn more.

A. Header Tank

The header tank includes a pressure gauge, pressure relief valve, diaphragm valves, and is connected to the solenoid valve. The header tank supplies compressed air to the body of the unit to pulse clean the fume extractor filters.

B. Primary Filter Door

This provides access to the body of the collector for easy change out of DeltaMAXX Prime fume extractor filters and includes a serial tag for quick reference.

C. Fork Pockets

Small footprint model compact dust collectors come with fork pockets, allowing for easy unloading and placement within any facility.

D. Discharge Access Door

The discharge access door allows for quick access to the material collection bucket to easily dispose of welding fume or laser cutter fumes.

E. Filter Gauges

These gauges help determine when it is time to change the fume extractor filters as well as the HEPA filter.

F. Control Panel

The Shadow's control panel is prewired for easy installation and has the capability to be run remotely when used as a laser fume extraction system.

G. Smoke Detector

A built in smoke detector is optional with the Shadow and will monitor the amount of smoke present inside the body of your collector.

I. HEPA Access Panel

This tool free access panel makes changing your industrial fume extractor unit's HEPA filter easy.

J. Multi-Directional Inlet

A multi-directional inlet provides up to five different options to connect for laser cutter extraction or welding fume extraction. Easily connect your Air-Port Fume Exhaust Hood for robotic and manual welding.

K. Floor Anchors

The Small Footprint model of the Shadow Compact Fume Extractor must be anchored to the floor for safety.

Four and six cartridge models standard. Custom sizes available upon request.

Just place, connect, and start.

The Shadow arrives fully assembled, eliminating the need for complex, on-site installation or special tools.

The fully integrated control panel makes the system plug-and-play with all wiring completed at the factory.

Safety Pentagon

Hover and click to learn more about the five features of the Safety Pentagon.

Double Gasket Pan

The double gasket feature simply ensures that there is a good seal between the cartridge top pan and the tube sheet, and that good seal is redundant by having two gaskets. If one gasket should happen to get damaged for any reason, the second gasket is there to achieve the seal.

Most cartridges in the industry rely on only one gasket to make this important seal. Without a good seal, there is risk of dust passing through the gasket, leading to leaking back into the facility or outdoor environment. The double gasket adds insurance that at least one gasket is there to reduce or eliminate this risk.

Completely Grounded

Bonding is the connection of non-current carrying conductive elements like enclosures and structures. Grounding is the attachment of bonded systems to the earth. Both are necessary to safeguard people and property from electrical hazards.

When dealing with combustible dusts, it is imperative that static electricity is addressed. If not properly addressed, a high risk deflagration could potentially be created. A simple design feature in the CMAXX and the Shadow is a bonding tab that makes contact with the cartridge top pan indexing channel. This bonds the cartridge pan to the collector once the collector's grounding lug is connected to the customer supplied grounding rod.

Anti-Ramp Lift Rails

The Anti-Ramp Rails are a simple design but vitally important. The rails accomplish what the name implies - keeping one cartridge top pan from ramping on to another cartridge top pan. Other vertical cartridge collectors available on the market risk top pans ramping on to one another if maintenance personnel do not carefully install replacement cartridges.

If even one cartridge happens to ramp up onto another cartridge, it voids the seal where the top pan gasket meets the tube sheet, allowing air and dust to pass through that space and exiting into the manufacturing facility or outside environment. Anti-Ramp Rails eliminate this risk, allowing maintenance personnel to replace cartridges confidently knowing that there is no risk of cartridges ramping.

Sure Stop System

The Sure Stop System design feature adds redundancy to cartridge replacement safety. This design feature ensures that the cartridges are completely and properly seated in order for the collector door to close. By combining a cartridge top pan indexing channel along with a door mounted indexing bar, the door cannot close unless the cartridges are installed properly.

If the cartridges are not fully pushed back, the bar will hit the channel and keep the door from closing. This ensures that mistakes can't be made when replacing cartridges. Between the Anti-Ramp Rails, the Lift Rail Door Stop, and the Sure Stop System there is built in redundancy ensuring cartridge replacements are done safely and without error

Lift Rail Door Stop

Another simple and effective design feature of the Safety Pentagon is the Lift Rail Door Stop. All vertical cartridges have a lifting mechanism that raise the cartridges to meet the tube sheet in order to obtain a seal between the dirty side and clean side of a dust collector. History has shown that maintenance personnell don't always remember to put the lift rail back into the seal position and it's not noticed until dust is blowing in to the facility or outside. The Lift Rail Door Stop eliminates this from occuring simply by not allowing the dust collector door to close if the lift rail is not in the proper raised position.

All it takes is for a lift rail to be left down one time to understand the huge benefits of having the Lift Rail Door Stop including saving on cleanup time, money, and operational downtime costs.

Anti-Ramp Life Rails

Double Gasketed Filters

Completely Grounded

Lift Rail Door Stop

Sure-Stop System

Robotic Welding

While robotic welders don’t have to be concerned with inhaling weld fume, it is still important to keep robots clean to keep them in good working order. Additionally, collecting fume produced by robotic welders keeps general air quality in the shop better as well. The Shadow is the perfect robotic welding fume extraction solution, and can be tucked away easily and kept out of the way of the robot. The Shadow is easily paired with these brands and many more:

|

• Kawasaki Robotics • Yaskawa • Motoman Robotics • Fanuc |

• Kuka Robotics • Mitsubishi Robotics • ABB Robotic

|

Plasma & Laser Cutting

The Shadow Compact Fume Extractor is the perfect solution for plasma and laser cutter fumes. This laser fume extractor’s multi-directional inlet allows for easy duct connection from your laser table. Our laser fume extraction system is designed to fade into the shadows and allow the laser table to be the focus. The Shadow is easily paired with these brands and many more:

|

• Mazak •Trumpf •Torchmate • Multicam |

• Messer • Piranha • Hypotherm • AKS |

• Koike • MC Machinery • ESAB • Hornet |

Manual Welding

Weld fume is very fine and easily breathable. It is crucial that any facility that welds in their shop also has a welding fume extractor system. The Shadow is easily connected to a fume extractor unit like the Air-Port Fume Exhaust Hood. With these two products, Imperial Systems can offer a complete system to capture and remove harmful weld fume from a welder’s breathing zone.

Check out our work with ReIgnite Hope, a non-profit organization teaching the trades and changing lives for struggling and unhoused persons in Los Angeles.

SERVICEMAXX SUPPORT FOR YOUR FUME EXTRACTOR

All our compact fume extractors are made in the USA. You’ll always have the full support of our dust and fume collection experts here in our Pennsylvania facility. Each Shadow Compact Fume Extractor is designed by our team of engineers.

Our professional ServiceMAXX teams can travel almost anywhere. They’ll make sure your Shadow is working as it should be. No other dust and fume extractor company offers better, more personal support.

The Shadow Compact Fume Extractor is designed for DeltaMAXX™ Prime Replacement Cartridge Filters. The DeltaMAXX™ Prime High Efficiency Replacement Cartridge Filter delivers the longest filter life, cleanest air and greatest cost savings.

With DeltaMAXX Prime nanofiber filters, the Shadow controls harmful metal fumes, such as laser cutter fumes and welding fumes. With an optional HEPA after-filter, it handles even strictly regulated materials like hexavalent chromium. A continuous pulse cleaning system keeps the fume extractor filters operating efficiently.

- 400 square feet of filter media for significantly more surface area

- Unique grounding for safety from static buildup

- Oval cartridge shape for more effective pulse cleaning

- Double gaskets prevent air leaks

- Low initial pressure drop for increased filter life

- Nanofiber material efficient down to 0.3 micron particle size

- Increased filter media improves air to cloth ratio

Frequently Asked Questions

Is the Shadow made for dust or fumes?

The Shadow uses standard DeltaMAXX Prime filters, which can filter dust or fumes. Because it is designed for noncombustible dust, the Shadow cannot be used for all applications. The Shadow is most appropriate for laser cutting, plasma cutting, light welding, and light noncombustible dust applications.

What size Shadow do I need?

The Shadow comes in several sizes. The size of your system depends on the size of your facility, the amount of airflow required, and how many points of capture you need. An undersized system will not move enough air to remove fumes properly. We can help design a system sized to your needs.

Will the Shadow be compliant with emissions standards?

The Shadow is designed to be installed indoors only. As a result, most Shadow systems will clean the air and return it to the facility, so no air is vented outside. An optional HEPA filter can make sure the air returning to the facility is a clean as possible.

Do I need a Shadow or a CMAXX?

The Shadow is appropriate if you 1) have noncombustible dust, 2) don’t need a large collector, and 3) plan to locate your collector inside. You may need to upgrade to a CMAXX if you 1) need combustible dust protection, 2) need to handle large volumes of dust, or 3) need to locate the collector outdoors.

How are filters cleaned in the Shadow?

The Shadow uses pulses of compressed air to blow particles off the filters. The Shadow has a differential pressure gauge that will let you check how well your filters are working and when to change them.

Filters should only be cleaned with this pulse cleaning system. Washing filters or taking them out to blow off dust will cause damage to the filters and create air leaks. Imperial Systems cannot be responsible for mishandled or inappropriately cleaned filters.

Why does the Shadow use vertical instead of horizontal filters?

With DeltaMAXX Prime filters, the Shadow packs a large filter surface area into a small footprint. The Shadow is designed for a low profile for indoor use. Vertical filters are easier to change, especially with the Shadow’s specially designed lift rails. They also pulse clean more efficiently, giving them a longer filter life. Learn more about vertical versus horizontal filters.

What's the best location for the placement of a Shadow?

The Shadow is designed as an indoor collector. For a collector that must be placed outside, see the CMAXX with weather protection features. Since the Shadow is only rated for use with noncombustible dust, it is safe to locate inside the building. Do not place the Shadow outside.

Is the Shadow rated for combustible dust?

The Shadow is NOT rated for combustible dust. It is designed as a lower cost option for facilities with noncombustible dust or fumes. For combustible dust, see the CMAXX dust and fume collector with optional IDA, as well as other fire and explosion safety features.

For noncombustible dust, the Shadow is safe and practical. A sprinkler system may be used for processes that create a lot of sparks.

How do I know if my material is combustible?

Dust testing is available to determine whether your dust or fumes are combustible. Generally, all organic dusts (sugar, grain, animal or plant materials) are combustible. Some plastics, resins, and metals are also combustible. Learn more about combustible dust here.

The Shadow is designed for laser cutting, plasma cutting, and light welding applications because testing has indicated that the fumes produced are not combustible. If there are questions, a dust test may be recommended to decide whether the Shadow is appropriate for you.

How do I calculate my air to cloth ratio?

The correct ratio of air to cloth (measured in cubic feet per minute of airflow and square feet of filter media) will depend on the type of dust and how your system is collecting it. For an ambient system the ratio may be about 4 CFM/1 square foot of media, while for a source capture system it may be closer to 1.5 CFM/1 square foot of media.

How do I calculate CFM (airflow)?

The easiest way to calculate CFM for an ambient system is to stop by our website and use our helpful airflow calculator. CFM (cubic feet per minute) is a measurement of duct area (in square feet) multiplied by the velocity of the air. If you are planning to use your Shadow as an ambient system, try our airflow calculator.

What is the correct airflow for my system?

Airflow calculations will include many factors, including the type of dust or fumes, the size of ductwork, and the number of sources where dust is being collected. Our Imperial Systems staff will custom design a system for your individual needs.

How long will my filters last?

Filter life will vary for every application. The DeltaMAXX Prime offers a very long filter life versus competitors, but results depend on type of material being collected, how many hours out of the day the system runs, and contaminants or larger particles in the material.

What is differential pressure and what does it tell you?

Differential pressure is the amount of resistance to airflow through the filters. It is the difference in pressure between the dirty and clean air plenums. A gauge measures pressure on both sides of the filter, and the reading tells you how much resistance there is across the filters.

Tracking differential pressure will allow you to tell when the filters have accumulated too much dust and need to be changed. If the differential pressure is too high, air is not flowing properly through the filters. See your owner’s manual for specific measurements.

When should I change my filters?

You should change your filters when the differential pressure reading is too high. Check your owner’s manual for specific measurements. There will be one differential pressure reading for the cartridge filters. If you are using the optional HEPA filter, it will have a separate reading.

What type of filter do I need?

Most Shadow collectors will use DeltaMAXX Prime nanofiber filters. These are only available from Imperial Systems, due to the proprietary pan and lift rails. For unusual applications, these filters are available in special materials such as moisture-resistant or nonstick PTFE. Our team has experience with many different applications and will help you choose the right filter.

How do I know if I need dust or fume collection?

Even noncombustible dust can be a safety and health hazard. Fumes from metal cutting and welding can have harmful effects, including lung damage and risk of cancer. The Shadow removes fumes from your cutting table or welding area. Without this, fumes can fill the work area, causing irritation to people’s eyes, noses, and throats.

What applications can the Shadow be used for?

The Shadow has been designed for specific applications. It is only for noncombustible dust, and only for installation indoors. If the dust or fumes are combustible, or if the collector must be put outside, the CMAXX is an appropriate choice. The CMAXX can handle heavier dust loads. Contact Imperial Systems to find out which collector is the best option for your dust and fumes.