Dust collector filter cartridges are a critical component of industrial dust collection systems. They help capture and remove harmful dust and fume from the air. Over time, the filters in these air filtration units become clogged with dust and debris. This reduces their efficiency and potentially compromises the air quality in your facility. It is important to know when to change your dust collector cartridge filters to ensure that your dust collection system is operating effectively and efficiently.

1. Monitor Differential Pressure

One of the most common ways to determine when it’s time to change your dust collector filter cartridges is to monitor the differential pressure across the filters. As dust and debris accumulate on the surface of the filters, it becomes harder for air to pass through them. This increases the differential pressure. When the differential pressure reaches the measurement specified by the machine manufacturer, it is time to change the filters. 5 – 6” w.g. is a common pressure threshold that the industry observes.

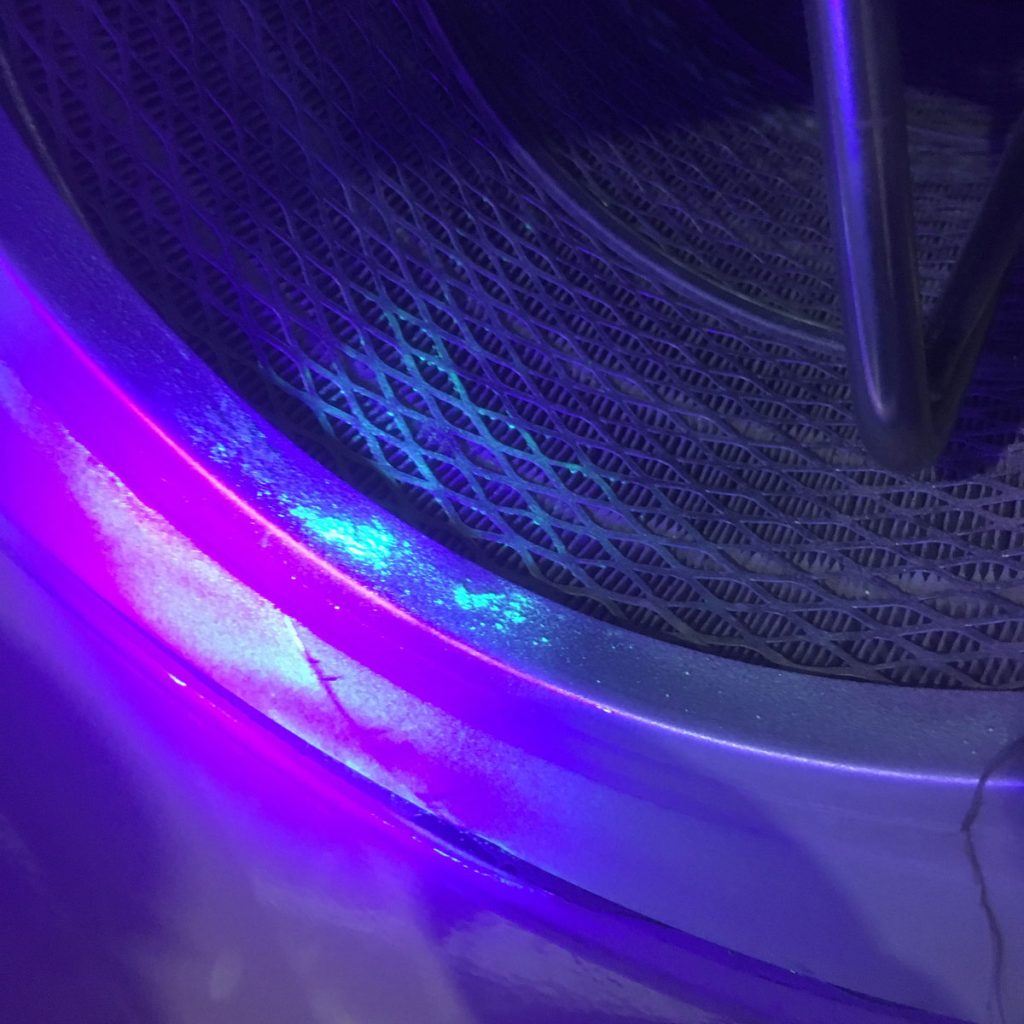

These filters are being tested with a UV light for leaks and holes.

2. Inspect the Filters for Visible Damage

In addition to monitoring the differential pressure, it is also important to visually inspect the filters for signs of damage or wear. If the filter media appears to be torn, ripped, or otherwise damaged, it is time to replace the filters. Similarly, if the seals appear to be worn or show signs of damage, replace the filters at that time. One indication that a hole or leak may be present would be a sudden drop in differential pressure or particulate blowing out of the dust collector.

3. Consider the Type of Dust and Application

The type of collected dust and the specific application can also impact how often to change the filters. Dusts that are particularly abrasive or corrosive, for example, may require more frequent filter changes than less abrasive dusts. Similarly, applications with high dust volumes may require more frequent filter changes than applications with lower dust volumes. Facilities that run multiple shifts may require more frequent filter changes than those that just run one shift.

Why Replace Your Dust Collector Filter Cartridges

Depending on what type of filters you need, how many filters you require, and how many dust collectors you have, doing a complete change-out can be costly. While it may be tempting to clean your dust collector filter cartridges to extend their service life and save on replacement costs, there are several reasons why replacing the filters is often a better option:

1. Reduced Filter Efficiency

Cleaning dust collector filter cartridges can be a messy and time-consuming process. It can also reduce the efficiency of the filters. When cleaning filters, some of the dust and debris can embed in the filter media, reducing the overall filtration efficiency. Over time, this can lead to increased emissions and decreased air quality in your facility.

2. Potential Health Risks

Cleaning dust collector filter cartridges can also pose potential health risks for workers. As dust and debris dislodge from the filters, they can become airborne and workers can potentially inhale them. This can lead to respiratory issues and other health problems.

3. Increased Maintenance and Downtime

Cleaning dust collector filter cartridges can also increase maintenance and downtime for your dust collection system. The cleaning process can be time-consuming and labor-intensive, and it may require specialized equipment or cleaning agents. In addition, cleaning the filters may not always be effective in removing all of the dust and debris, which can lead to more frequent filter changes and increased downtime for your dust collection system.

4. Damaged Filters

Cleaning your dust collector filter cartridges may cause potential damage to the media or structure of the filter. Many filter cartridges are designed receive an even distribution of compressed air during cleaning inside the filter housing. A concentrated blast of compressed air to a specific area, such as during a manual clean, may create tears or introduce small holes in the media, rendering the filters useless.

Conclusion

Overall, it is important to monitor the differential pressure and condition of your dust collector filter cartridges regularly and to replace them when necessary to ensure that your dust collection system is operating effectively and efficiently. While cleaning filters may seem like a cost-effective solution, replacing them can help to ensure that your facility is maintaining the highest level of air quality and worker safety. If you’re uncertain whether or not you need to replace your dust collector filters, contact the filter team at Imperial Systems for more information.