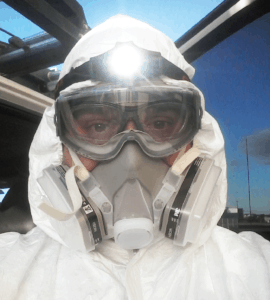

Correctly using PPE (personal protective equipment) can be very effective. So why does OSHA consider it a “last resort” for health and safety? Let’s take a look at PPE and engineering controls and explore what is practical for certain situations.

Viable Risk Protection

While PPE is often essential, it should only be used to protect people from risks that cannot be controlled in any other reasonable way. For example, a helmet with a face shield is often the only reasonable way to protect a welder’s face and eyes because they are often very close to the welded metal. On the other hand, a respirator is much more difficult to wear and use correctly than a welding helmet, so welding fumes are better handled by engineering controls.

Engineering controls, such as dust and fume collection, and safe work practices are more effective and protect everyone, not just the people wearing PPE.

There are a lot of reasons why PPE shouldn’t be the first line of defense in keeping people safe. Some of them are listed here:

- instructions for use not given or not followed

- not fitted correctly

- appropriate PPE not provided

- is uncomfortable, hot, blocks vision, or other problems

- faces must be clean-shaven for respirators to fit properly

- makes moving around and doing job difficult

- takes too long to put on and take off

- is dirty, worn out, or otherwise not functioning as it should

- only protects the person using the PPE, not people around them

- loses, breaks, or damages the PPE

Realistically, people often don’t like PPE. It can be awkward and uncomfortable (especially in the heat) and can restrict vision and movement, make tasks more difficult, and take up a lot of time. Problems like this may keep people from using PPE, or keep them from using it as much as they should. And that’s assuming that proper PPE is always available… which it isn’t.

Engineering Controls Considered Best Workplace Strategy

Engineering controls are often the first line of defense that OSHA recommends for many exposures and other safety hazards. Basically, engineering controls modify the workplace to reduce or eliminate health and safety risks. This may include adding safety devices, enclosing equipment, source capture of dust and fumes, switching to a less dangerous chemical or process, or changing the layout of a facility. OSHA considers these to be “the first and best strategy” for health and safety in the workplace.

Dust collectors are a good example. If a process is creating dust or fumes that could harm employees, a dust collection system can remove those materials from the air completely. This reduces or eliminates the need for respirators, and the dust never has an opportunity to spread through the workplace and affect people in other areas. Dust collection systems can provide source capture at specific work areas. They can also filter the air throughout the facility, depending on the type of required system to capture the dust or fumes. Dust and fume collectors can serve an important role in overall engineering controls for safety.

References:

https://www.linkedin.com/pulse/your-ppe-last-resort-has-real-limitations-terry-penney

http://www.healthyworkinglives.com/advice/work-equipment/ppe

https://www.newpig.com/expertadvice/why-osha-demands-engineering-control-first-ppe-last/