Learn how to avoid dust combustion at your metalworking facility.

The metalworking industry is familiar with the perils of having polluted, particulate-ridden air. According to the Occupational Safety and Health Administration the following 5 elements can cause a devastating blow to any manufacturing plant:

- Fuel – Combustible Dust

- Ignition Source – Sparks

- Oxygen

- Dispersion of Dust Particles

- Confinement

So what is the solution to preventing an instantaneous combustion from dust along with the other threatening elements to your facility? The right answer is to install one of North America’s top quality laser and fume extraction systems. The better answer is to install the top quality CMAXX™ Dust Collection System with an in-line spark trap from Imperial Systems.

So what is the solution to preventing an instantaneous combustion from dust along with the other threatening elements to your facility? The right answer is to install one of North America’s top quality laser and fume extraction systems. The better answer is to install the top quality CMAXX™ Dust Collection System with an in-line spark trap from Imperial Systems.

The Benefits of An In-Line Spark Trap

What’s the purpose of an in-line spark arrestor?

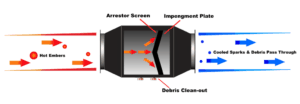

Imperial Systems in-line spark traps are meant to be the first line of defense in preventing potential dust explosions. An in-line spark trap prevents potential fire hazards by containing the spark before it finds its way to the combustible dust or any other potential fire hazard in the main unit of your dust collection system.

Take into account these number when considering the purchase of an in-line spark trap:

- Metal dust accounts for 20% of the explosions that occur nationwide

- 7% of ignitions sources are caused by fabricated metal

- 8% of ignition sources are caused by Primary Metal

When going over the pros and cons of purchasing the CMAXX™ system there really are no cons. Your fume extraction system is a preventative measure to ensure the safety of your metalworkers. The in-line spark trap is just another form of insurance that will neutralize the threat of a fatal explosion.

What Else Does the CMAXX™ Dust Collection System Offer?

The CMAXX™ Dust Collection System has 10% more filter media than other same-sized vertical cartridge collectors. The internal area of the CMAXX dust collector system offers 20% more area around the cartridge filters causing more dust to drop in the hopper before attaching to the filters.

- Space Saving – Low Profile Design, Small Footprint

- Vertical Cartrige Design – Longer Filter Life

- Best in Class – Internal Velocities are 20% Lower

- Military Grade Door Latches. No Truck Trailer Hardware.

- 15 Year Manufacturer’s Warranty

- Lowest Internal Velocities from a Larger Housing – Longest Filter Life

- Graphite Industrial Enamel: Corrosive Resistant Paint; Inside and Outside

- Energy Efficient, High-Performance Manifold Mounted Pulse Valves – Increased Cleaning Power

- Tool-free, Heavy Duty Filter Door – Less Service Time

- Modular Design – No External Bolts on Dirty Air Plenum – Less Chance for Water and Air Leaks

- Heavy Duty 7 & 10 Gauge Construction; Nickel Plated Hardware

- Air Pressure Gauge on Compressed Air Manifold

- High Efficiency – Cleaner Plant Air

- PD Technology – Up to Twice the Filter Life

- Factory Assembled Air Header and Top Section – In Most Cases, Hopper and Legs Ship Disassembled

- No Internal Frame on Dirty Air Plenum – Fewer Internal Ledges for Material to Build Up

For more information on our in-line spark arrestors or our CMAXX™ Dust Collection System contact Imperial Systems today!