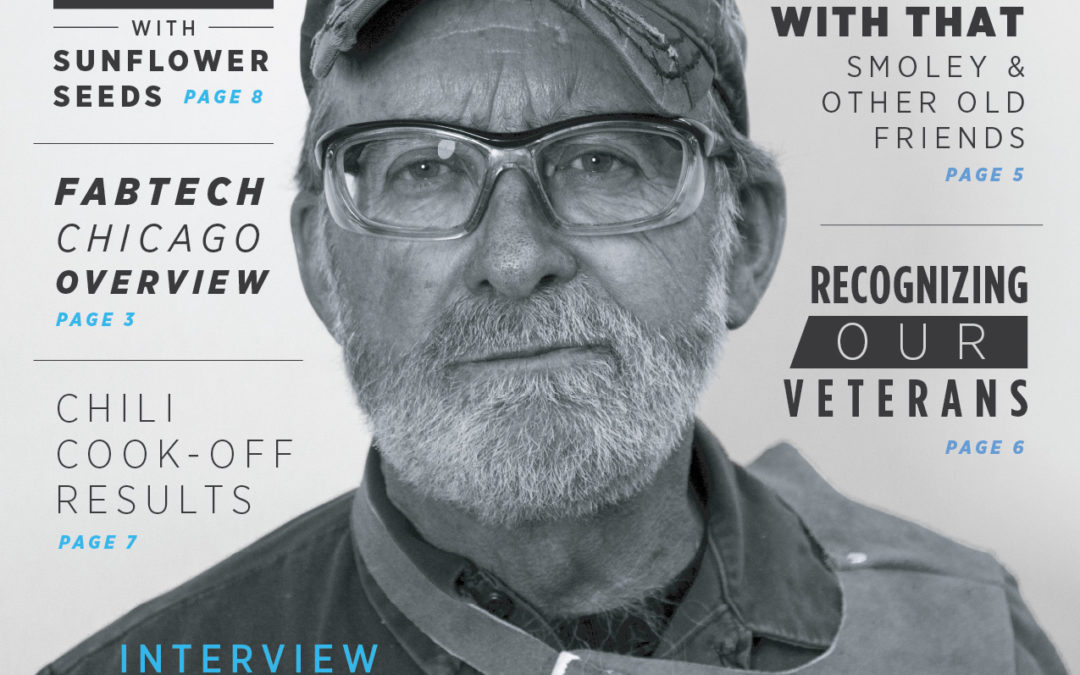

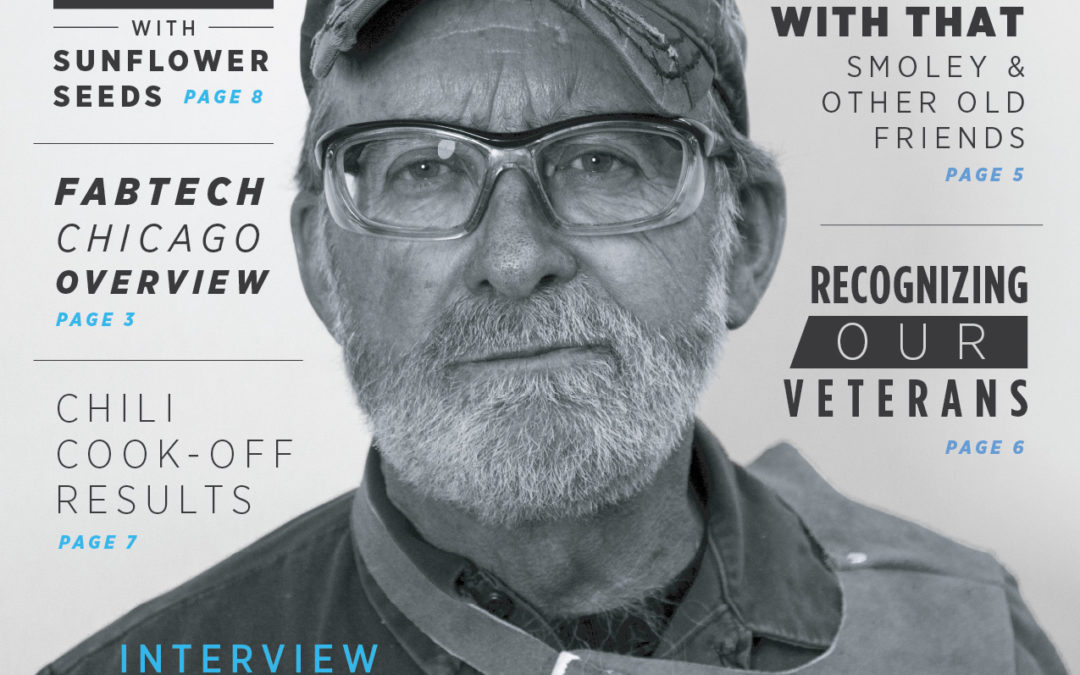

by Scott Stearns | Dec 20, 2017 | Hidden from Archive

Steve has been welding for just about 44 years, with ten of those years being here at Imperial Systems. He enjoys hunting and will watch a Steelers game if it’s on, but his medical treatment doesn’t leave much time for other hobbies. He lives in the small town of Stoneboro with his wife and their three dogs, with his daughter living nearby.

Q: You’ve been here ten years. What was it like when you started?

A: It was definitely different. There were only about eight of us at the beginning, and then we just kept getting more people. Pretty soon we were stepping all over each other, till they added the expansion.

Q: So what did you get during hunting season this year?

A: Got a buck during archery and then a doe. You gonna put that in there too?

Q: All right, then… tell me about your dogs.

A: You just want to talk about everything, don’t you. We’ve got three dogs. One’s a collie and the other two are yorkie-poos.

Q: Wait… yorkie-poos?

A: (with a look daring me to say something about it). Yeah. Yorkie-poos. Half yorkie and half poodle.

Q: So tell me how you ended up here.

A: I needed a job. I was working at another company, doing fabrication, and they pissed me off. They wanted me to use inferior material, and I wasn’t going to do it. They told me I didn’t have a choice, so I gave them my two weeks’ notice. Nobody tells me I don’t have a choice.

Q: So what’s kept you here for ten years?

A: They haven’t pissed me off enough to leave yet. No it’s not a bad place to work. Jeremiah is a good guy to work for.

Q: How long have you been doing metalworking?

A: Since I was nineteen years old.

Q: Where did you learn to weld?

A: On the job. Had three weeks of training, and then I was out learning from experience. Working on railroad cars.

Q: Favorite kind of equipment?

A: I’ve used pretty much all of it. Miller, Lincoln, Hobart… I don’t really have a preference.

Q: What’s the one piece of equipment that helps you the most doing your job?

A: It’s gotta be the hoist. The doors, once you’ve got them assembled, they’re so heavy you can’t move them. I couldn’t do my job without that.

Q: What would you tell somebody who was interested in getting into it as a career?

A: I’d tell them to go into healthcare. But if it’s what someone wants to do, I’d tell them to go for it. If it’s what you love, you’ll be happy doing it.

Q: You’ve had some experience with the healthcare thing. I know your daughter is a nurse, because she was yelling at you one day about taking care of yourself.

A: Yeah, she does get on me about that.

Q: Can we talk about the dialysis and being on the donor list for a kidney?

A: Sure. It’s not a secret. Everyone around here knows about it. There have been two people who volunteered to be donors, but they didn’t qualify.

Q: You leave here after work and go straight to dialysis, right?

A: I spend a lot of time there.

Q: I heard you’re pretty popular there.

A: Well, that’s because I don’t walk in there like I’m half dead. First time I went in there it was like walking into a morgue. I bring some life into the place.

Q: You definitely aren’t half dead.

A: (grinning). No, I’m not!

Read more

by Imperial Systems | Dec 14, 2017 | Uncategorized

Managing weld smoke risks means dealing with very small particle size, toxic metals, and the combustibility of metal dust. Weld smoke and fumes are different from other types of dust, and a system needs to be designed to deal with it. A CMAXXTM dust and fume collection system will meet any metalworking or weld smoke control needs.

WELD SMOKE RISK: HEALTH

One of the risks of weld smoke is hexavalent chromium. This compound can cause skin sores and lung damage, and cancer of the lungs, kidneys, and other organs. Many metals are alloyed with chromium to make them corrosion-resistant.

Most of the particles in welding fumes come from the welding wire, but some of them come from the material being welded. Some of them can cause allergic reactions and an immune response called “metal fume fever”. Lead and manganese can damage the brain. Others, like hexavalent chromium and nickel, are known carcinogens and increase your risk of cancer. Learn more about welding fumes and cancer.

The particles that are put into the air as fumes from welding are extremely small. Most are smaller than one micron. This means they are small enough to get inside human cells and cause damage. This also means that welding fumes are lighter than air, especially when heated. A system for collecting these fumes must be designed to handle very small particles.

MANAGING WELD SMOKE RISK: FIRE AND EXPLOSION

Welding produces metal dust and gases that may be combustible. Some metals, such as aluminum, are very explosive as a dust. Almost all metal dusts have the potential to explode. Handling welding fumes means using appropriate fire suppression and prevention measures.

Suppressing sparks to keep them from getting into the collector can help prevent explosions from welding smoke dust. Spark Arrestors are important in keeping most sparks from getting to the collector. An explosion isolation valve can prevent a fire from traveling back through the ductwork. Chemical control systems can suppress or extinguish a flame, but only certain chemicals are approved for fires involving metal dust.

Filters can also be important for fire suppression in a welding smoke system. Filters with a fire-retardant coating they will resist burning and help control a deflagration. Some collectors are designed with filters that help isolate an explosion and keep it from causing damage inside the workplace. DeltaMAXXTM filters with fire-retardant coating will prevent a fire from occurring inside a dust collector.

HANDLING WELD SMOKE

Figuring out what type of fume extraction system to use in your facility is an important decision for managing the risks from weld smoke. Our systems engineers will consult with you to help you determine the best way to manage your weld smoke risk.

If there are not very many welders and they don’t always work at the same place, portable collectors can be a solution. They can be useful for handling point of source capture. An ambient system is designed to move a volume of air out of a large area and through filters.

For managing weld smoke, portable collectors can be easily moved around, but they are not as powerful as a larger collector. Central collectors are the most efficient for large areas, but if they are inside they take up floor space. Locating the collector outside is usually recommended for safe explosion venting.

One of the biggest advantages with an ambient system that recirculates the air back into the facility is energy cost savings. When heated or air-conditioned air is vented outside, the energy used is lost. Many businesses find that a fume collection system can pay for itself within two years with the money saved in energy costs.

CMAXXTM dust and fume collectors have proven themselves in the welding and metalworking fields. Our newest product, the SHADOWTM portable collector, gives you even more options for managing weld smoke . DeltaMAXXTM nanofiber filters are the best available material for capturing metal fumes. At Imperial Systems Inc., we are committed to helping you control your weld smoke risks.

(as seen in The Fabricator Magazine)

Read more

by Imperial Systems | Dec 6, 2017 | Uncategorized

An explosion inside a dust collector can be a disaster if there is no explosion venting (also called deflagration venting). Obviously, the first priority is to make sure that no sparks or heat sources have a chance to get inside the collector. However, even the best safety precautions aren’t 100% foolproof. If a dust explosion occurs in your dust collector, how will explosion relief be handled safely?

Explosion Venting Considerations

The method you choose for venting an explosion will be based on several factors:

- Location of the dust collector inside or outside the building

- Distance of the dust collector from roof or walls

- Proximity of the dust collector or vent to other structures

- Cost efficiency

Outside Installation

The first and safest method of venting a dust explosion is to have the collector located outside the building. In this case, any explosion that occurs will be vented safely with appropriate venting.

The issue with this method has to do with safety distance. Specifically, explosion relief vents must be located far enough away from anything that the energy vented might damage. Space around the dust collector, especially near the explosion vents, must be clear of anything that could be damaged or ignited.

Many areas have state and/or local regulations for fire safety and explosion venting. Locating the collector outside when possible is usually the easiest way to meet these standards.

Inside Installation

What if your dust collector must be inside the building? There are various reasons for this, depending on your system setup. For example, it’s possible that the collector must be centrally located. Also, it might need to be close to or attached to a certain piece of equipment.

If you can’t put the collector outside, you will have to divert the energy of an explosion. The most common way to do that is to vent the explosion to the outside, either through a wall or through the ceiling. The area outside needs to be safe just like it would need to be around a dust collector, free of anything that could be damaged by the explosion. A deflector shield can redirect the explosive force in a safe direction.

If you can’t put the collector outside, you will have to divert the energy of an explosion. The most common way to do that is to vent the explosion to the outside, either through a wall or through the ceiling. The area outside needs to be safe just like it would need to be around a dust collector, free of anything that could be damaged by the explosion. A deflector shield can redirect the explosive force in a safe direction.

What happens if your dust collector is inside the building and you’re not close enough to a wall or ceiling to vent that way? This could be a very dangerous situation, with a collector inside your building and no way to get an explosion safely outside.

In this case, a flameless dust collector explosion vent may be the only safe option. While these safety devices are not cheap, they are essential for venting an explosion safely inside a facility or anywhere else that flame from the venting could be dangerous.

A flameless explosion vent design is made of a tightly wound metal mesh. It’s designed to extinguish the flame and dissipate the heat from an explosion. It takes up less space and is less expensive than other explosion protection systems. It is ATEX certified and NFPA 68 and 61 compliant.

Venting Solution Priorities

We recommend looking at explosion venting solutions in the following order, based on cost and safety:

- Locating the collector outside

- Venting the collector through a wall or ceiling

- Installing flameless venting

We also recommend always consulting your local building codes and regulations. Some areas have very specific regulations for fire safety and environmental safety.

Read more