by Imperial Systems | Mar 8, 2016 | Uncategorized

The DeltaMAXX™ advantage gives you results your desire!

A metalworking plant requires the use of quality dust collector systems, and efficient industrial dust collector filters to protect metal fabricators from the dangers that face daily. What are your essential needs when looking for replacement filters for your dust collector? As a metalworking business owner your needs are simple. You want industrial dust collector filters that will give you the security you need while providing you with the savings you want.

In the last 30 years, there have been over 700 injured and 119 deaths due to combustible dust incidents in all forms of manufacturing according to the U.S. Chemical Safety Board. In order to combat such tragedies, Imperial Systems goes above and beyond the safety guidelines established by the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA). We’ve spent over a decade of our business innovating dust collector industrial filters, and we continue to improve in order to stay one step ahead of your needs.

The DeltaMAXX™ Advantage of our Industrial Dust Collector Filters

Up to Twice the Filter Life

Up to Twice the Filter Life- Advanced NanoFiber Technology

- A Superior MERV 15 Filtration Efficiency

- Lower Operational Mass Emissions

- Less Pulse Cleaning

- Highest Quality Pleated Media – 99.9% Efficiency .3 to .5 Micron

- Best Surfacing Loading Performance

While these advantages of the DeltaMAXX™ industrial dust collector filters are certainly impressive, how does it translate into the safety and savings you need for your metalworking business?

The nanofiber technology that is used in our filters stops submicron particles from entering and becoming embedded into the media beneath the nanofiber. Giving our filters a higher efficiency rating due to the nanofiber technology being 50% smaller than competitive fibers improving our DeltaMAXX™ filters filtration by of 50% (.3-.5 Microns). This allows for a lower resistance to airflow due to our impressive surface loading technology and enhanced dust cake release.

Metalworkers benefit from the added safety of our surface loading technology by reducing their exposure to toxins. The best surface loading technology has less dust build up. Less buildup of dust requires fewer pulses, and fewer pulses means reduced emissions and fewer safety hazards.

With our filters requiring fewer pulses this decreases the stress they are under and increases the life of the filter. In fact, our DeltaMAXX™ industrial dust collector filters pulses up to 94% less often than our competitors. The advantages of our DeltaMAXX™ filters give you longer filter life, increases efficiency, reduced emissions, fewer safety hazards, and increases savings.

When you need a company that goes above and beyond the standards of metalworking industry contact Imperial Systems!

Read more

by Imperial Systems | Mar 8, 2016 | Uncategorized

Don’t let any more lives hang in the balance! Call Imperial Systems for your baghouse filter changeout.

In the food processing industry, your objective is to maintain a safe and sanitary food processing environment. The clean processing environment is critical to avoid cross-contamination of food and the safety of the employees. When you think of the food processing industry your initial thought might not be one of danger. However, the dangers that lurk in the food industry is that of combustible dust.

Within the food processing industry is grain handling where oats, wheat, corn, sunflower seeds, and barley are processed. The Occupational Safety and Health Administration says that grain handling has some of the most dangerous hazards within the industry. So how do you keep the dust and particulates under control? With Imperial Systems high-quality Bag House Dust Collector Systems, and the DeltaMAXX™ Bag House Filter Changeout.

The BRF Bag House Dust Collection System is made for dependable functioning with a seven and ten gauge construction and accurate welds. We have designed it to be reliable and convenient with easy access to maintenance features and an ability to be adaptable to any workspace. The other benefits and advantages are:

- Explosion venting that meets NFPA guidelines

- Minimal wear on parts

- Cleaning system comes with an 8-year warranty

- Explosion-proof electric motors within the clean air plenum

- Accommodates higher dust loads

- Superior cleaning system

- Strong and Precise welds

- Sprinkler System in the clean air plenum

- Minimum wear on parts

When You Need A Bag House Filter Changeout, Think DeltaMAXX™ Bag House Filters

Our DeltaMAXX™ Bag House Filters deliver the longest filter life providing your food processing plant with the cleanest air, and giving you the greatest cost savings. The Welded Seamed replacement bag filter offers the advantage of reducing the risk of fine particles leaking through the needle holes and eliminates the possibility of damage to the filter bag due to the abrasive dust that can tear apart the sewing thread at the seam.

Our welded seam replacement filter bags are produced in a more cost-effective way providing you with the savings and safety you desire. If you’re in need a sewn seamed replacement filter bags we can provide those for you as well. Need us to do your bag filter calculation? We’ll take care of it.

Imperial Systems is your baghouse filter supplier, dust collection, and air pollution control expert. We design and install dust collection systems to all manufacturing industries. If your grain handling plant is in need of an upgraded baghouse dust collection system or you’re needing to find a better quality baghouse filter changeout, contact us today.

Read more

by Imperial Systems | Mar 3, 2016 | Uncategorized

Imperial Systems is your go-to resource for safe, effective industrial dust collector systems, filters, and ductwork.

As metalworking processes and technologies have developed over time, so have the innovations in efficient dust collection equipment and design. Imperial Systems is consistently on the cutting edge of these growing needs and continues to design and manufacture products that preserve the industry’s safety and efficiency standards – including baghouse systems. Whether you are updating an older facility or investing in a new one, we have the best baghouse collector filters and systems to keep your facility safe and efficient for a long time to come.

How Baghouses Work

Baghouses are air quality control devices with fabric filters that capture or separate dust and other particulate matter. Baghouses are incredibly versatile and can be adapted for almost any dust-generating application. Their applications range from small household workspaces to large industrial facilities.

Baghouses are air quality control devices with fabric filters that capture or separate dust and other particulate matter. Baghouses are incredibly versatile and can be adapted for almost any dust-generating application. Their applications range from small household workspaces to large industrial facilities.

A filter bag house consists of filter media (bags) suspended inside a casing. A fan on the outside sucks in the contaminated air from the factory which flows into the baghouse and through the filters. While filtering, the bag develops a layer of particulate matter on its surface called a dust cake. This dust cake continues to build until its thickness sufficiently restricts the airflow. At this point, the bags must be replaced.

The Imperial Systems Advantage

To help meet the needs of metalworking, food and grain processing, and other applicable industries, Imperial Systems has created the BRF Baghouse Dust Collector with the following highly competitive features:

- 8-year warranty on the cleaning mechanism

- Explosion-proof electric motors in the clean air plenum

- NFPA approved explosion venting

- Sprinkler system in the clean air plenum

- 60° hopper with access door

- Top access, tool-free bag and cage removal

- Factory assembled ladders and platforms

- Large access platform

- Standard design for 25” negative pressure

- And much more!

Imperial Systems also offers DeltaMAXX welded seam replacement filter bags, the best baghouse collector filters on the market. These filters are heat sealed – reducing the risk of fine particles leaking through the needle holes and eliminating the risk of abrasive dust tearing apart the sewing thread at the seam. Their production process is also less costly than sewn seam filter bags, reducing your business expenses.

Selecting the best baghouse collector filters when replacing baghouse filter bags will increase filter life, maximize your system’s performance, and reduce downtime…all of which boosts your business’s health and bottom line. A proper bag filter calculation will ensure that the baghouse will function correctly. Regardless of the nature of your dust collection and air pollution control application, Imperial Systems, Inc. has the answer for all of your filtration needs.

If you are ready to see the difference best baghouse collector filters and collectors can make for your facility, contact Imperial Systems today. Our customer service representatives pride themselves in providing the most accurate and up-to-date information, optimal dust control solutions, and outstanding service for our clients. Give the experts at Imperial Systems a call at (800) 918-3013.

Read more

by Imperial Systems | Mar 1, 2016 | Uncategorized

Find out how metalworkers like you can address the need of a top-quality spark

It’s no secret that the materials you work with everyday in the metalworking industry can create a serious risk for combustion. In fact, metals make up 20% of the materials involved in combustible dust incidents. And between 2008 and 2012, the United States Chemical Safety Board documented 50 combustible dust accidents, which led to a total of 29 fatalities and 161 injuries.

The spark trap is the solution to a very dangerous problem and the need to invest in the most advanced spark trap is clearly an essential safety decision that we at Imperial Systems take very seriously.

In fact, continuing customers rely on Imperial Systems when quality is of the utmost importance because they know Imperial engineers outstanding, high quality products to keep buyer’s employees and businesses safe from dust collection and the risks of combustion in the metalworking industry.

At Imperial Systems, we are dedicated to to helping metalworkers like you ensure the safety of your employees and efficiency of your workplace. We’ll discuss:

- Why a cutting-edge spark trap is of the utmost importance.

- The risks of an inefficient spark trap.

- Why the Imperial Systems spark trap keeps your employees safe from combustion hazards.

Why Invest in a Quality Spark Trap?

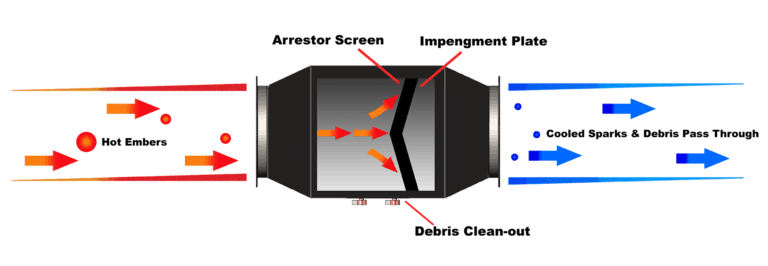

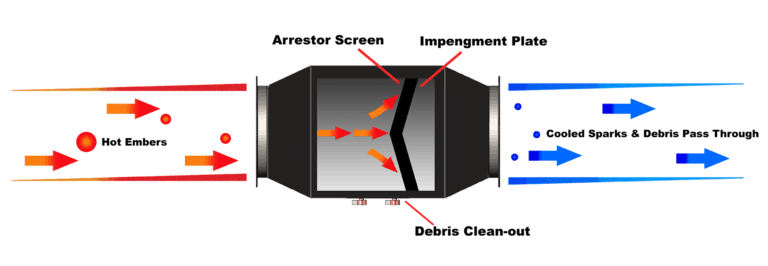

Designed primarily as a first line of defense to prevent ignition within a dust collection system, spark traps reduce the potential for fire hazard by capturing sparks before they reach the main containment unit, where dust or other flammable materials may be present.

The risk associated with a spark trap that functions inefficiently to achieve the above scenario every time is that it only takes one small failure of the system to put your employees in a deadly situation.

Companies in the metalworking industry should consider implementing ways to control the elements of a combustible dust explosion. The NFPA recommends several practices and policies to prevent combustible dust explosions, including:

- use of dust collection systems and filters and surfaces that minimize dust collection

- use appropriate electric equipment and wiring methods

- controlling static electricity, smoking, open flames, sparks, and friction

- install and use spark/ember detection, extinguishing, sprinkling, and explosion protection systems

A spark trap, or spark arrestor, is an instrumental part of these methods, working to minimize risk by cooling and thus extinguishing sparks before they reach the filter surface. In the diagram above that shows the process of an Imperial Systems spark trap, note how the hot spark enters the arrestor which both cools and collects debris, before allowing the cooled ember to pass through.

The Cost of Procrastination: Why an Imperial Systems Spark Trap is Essential to Safety

An ineffective or entire lack of a proficient spark trap leads to an increased risk in danger associated with the metalworking industry. Without it, sparks can reach the main component, where dust and flammable materials fill the air, causing an explosion.

- A simple installation: Our unique spark trap system does not require upkeep from their providers, meaning they are hassle-free in addition to being simple to install and pre-wired. With tool-free filter access and change out, they do not require any moving parts or additional welding.

- Optional sizes and features: You can choose between a carbon and stainless steel finish. In addition, you can choose to include raw inlets, outlet edges, an integrated HEPA after filter, and more to your spark traps.

- Customized fit: With both horizontal and vertical configuration options, an Imperial Systems arrestor can be aligned to your collector without fail.

Your metalworking company is not like other businesses where the environment is at increased risk with the potentially explosive combination of combustible dust and sparks flying. It is vital that you act immediately to implement all of the required and recommended OSHA and NEPA safety equipment, including dust collection systems with sealed ductwork and an effective spark trap.

Choose Imperial Systems Today

https://www.isystemsweb.com/

If you haven’t yet decided on a spark extinguisher for your metalworking business, what is that procrastination costing you?

From 1996-2005, 106 explosions resulted in 16 fatalities, 126 injuries, and an estimated cost of $162.8 million in damages to the facilities.

As we know, sparks are a major cause of such explosions and an Imperial Systems spark trap is an essential piece of equipment that can mitigate the fears and risk of an explosion.

Contact Imperial Systems today at 800.918.3013 or learn more by emailing us at info@isystemsweb.com.

Read more

Up to Twice the Filter Life

Up to Twice the Filter Life

Baghouses are air quality control devices with fabric filters that capture or separate dust and other particulate matter. Baghouses are incredibly versatile and can be adapted for almost any dust-generating application. Their applications range from small household workspaces to large industrial facilities.

Baghouses are air quality control devices with fabric filters that capture or separate dust and other particulate matter. Baghouses are incredibly versatile and can be adapted for almost any dust-generating application. Their applications range from small household workspaces to large industrial facilities.