by Imperial Systems | Jul 26, 2017 | Uncategorized

Part of the Trump administration’s push to support American manufacturers has involved cutting back on regulations. Several OSHA regulations in progress, including the new silica and beryllium exposure limits, have had their start dates pushed back so they can be reviewed. For industries that deal with the risk of combustible dust, one of the biggest changes may be that the administration has removed the proposed combustible dust regulations from OSHA’s agenda.

What was the plan for combustible dust regulations?

The delayed silica and beryllium regulations had already been put in place before the Trump administration requested review of them, and you can expect that they will still be implemented at some point. The combustible dust regulations, though, had been discussed, debated, and delayed for a long time before the current president took office.

The Chemical Safety Board (CSB) is an independent federal agency that investigates industrial accidents, including dust explosions. They have been pushing for combustible dust regulations for years, with one major push coming after the disastrous Imperial Sugar dust explosion in 2008, where one smaller explosion ignited sugar dust that had accumulated all over the building, killing 14 people and completely destroying the facility.

Another incident that prompted the CSB to push for combustible dust regulations was a titanium dust explosion in West Virginia that killed three workers in 2010. Throughout the next several years, the CSB kept combustible dust regulations on its “most wanted list” of new rules it considered necessary to prevent industrial accidents and deaths.

There are already combustible dust regulations for the grain industry, where explosions from dust in silos, elevators, conveyors, and mills is a constant hazard. The CSB and other safety organizations hoped to push this type of regulation to cover all types of combustible dust.

What kept the combustible dust regulations from happening?

Every year OSHA reviews laws and regulations they want to work on. Combustible dust regulations have been on that list for several years, but have been delayed or not decided on. The main problem is that such a regulation would affect nearly any industry that produces dust, since almost all dust is potentially explosive, and every process that causes dust to be produced.

With uncountable numbers of different types of dust and different processes, making combustible dust regulations that could cover all of these was a very difficult task from the beginning. This kind of regulation would have to cover industries from food to metalworking to plastics to pharmaceuticals. It would be a huge job to figure it all out and make it enforceable.

Does that mean OSHA can’t fine you for combustible dust problems?

Except for the grain industry, OSHA does not have combustible dust regulations that they can use to fine violators. However, they have issued many guidelines and recommendations for combustible dust safety. These are not enforceable. However, that does not mean combustible dust can be ignored. OSHA does have enforceable regulations for fire protection, ventilation, general environmental controls, and hazardous materials. Uncontrolled dust in your facility may be a violation of any of these.

In addition to these rules, OSHA can enforce serious fines in situations where workers are injured or killed on the job because employers did not correct a dangerous situation. In the event of a combustible dust explosion with injuries or deaths, serious penalties could be enforced for letting a hazardous situation occur.

Even without concern for combustible dust regulations, lawsuits against a company for injuries or deaths in a dust explosion are quite likely, and they could cost much more than any OSHA fine.

What guidelines should you follow to prevent combustible dust hazards?

The National Fire Protection Association (NFPA) does not make combustible dust regulations. However, they do set standards for managing combustible dust and preventing dust fires and explosions. NFPA standards are often considered the industry standard, and many local and state building codes require that facilities meet NFPA standards. NFPA 652 and 645 deal specifically with combustible dust.

Even though OSHA does not have combustible dust regulations, state and local safety administrations or building codes may have regulations that are much stricter than OSHA’s. NFPA standards are the gold standard by which many state and local governments set their safety regulations.

Why are engineering controls such as dust collectors so important?

The only good way to keep combustible dust from creating an explosion hazard is to get it out of your facility. Since blowing industrial waste into the surrounding atmosphere tends to be frowned upon, a dust collection system that filters the combustible particles out of the air can be the best solution.

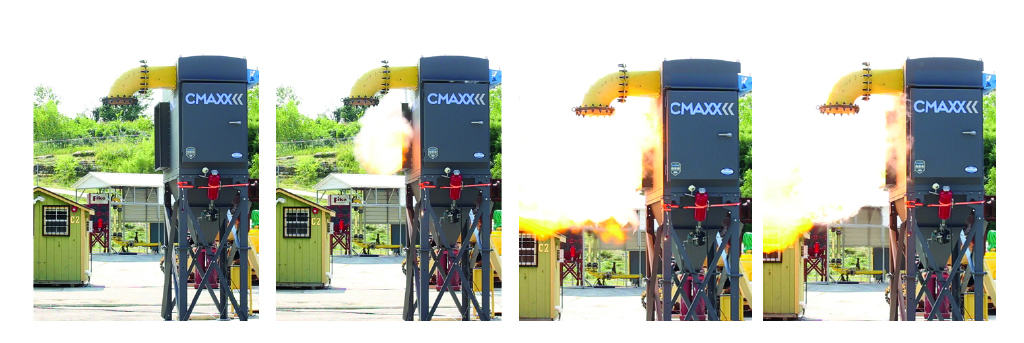

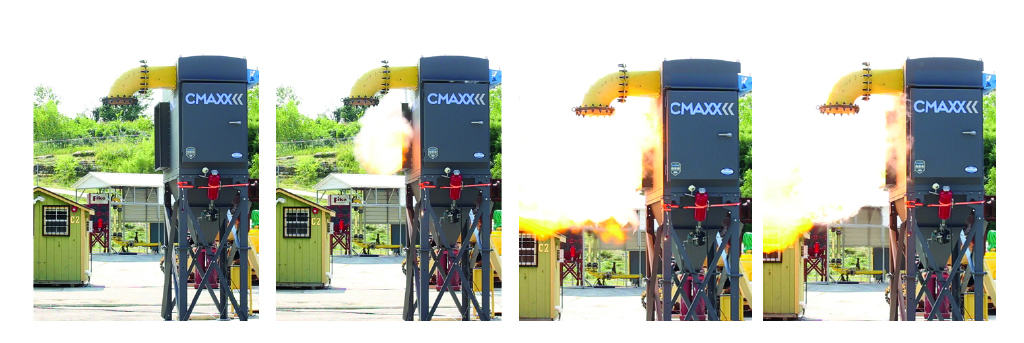

Even if a fire does occur in a dust collector, properly designed systems will have safety features such as fire suppression, explosion venting, and abort gates to safely control or divert a combustible dust explosion. While OSHA does not have a regulation to enforce dust collectors for combustible dust, they do strongly recommend them, and the NFPA also strongly recommends a well-designed dust control system as a key safety feature.

Read more

by Imperial Systems | Jul 5, 2017 | Uncategorized

If your company is following the principles of lean manufacturing, is your dust collection system keeping up? Lean is everywhere, eliminating waste and improving processes. However, many companies trying to find lean solutions haven’t taken a look at that ancient baghouse rusting away behind the building. Can you apply any of these lean solutions for dust collection?

In our last post we talked about an efficiently running dust collection system, and how this reduces waste and saves time and money. This time, we’re going to look at the system design and see whether yours is as lean as it could be.

SITUATION 1:

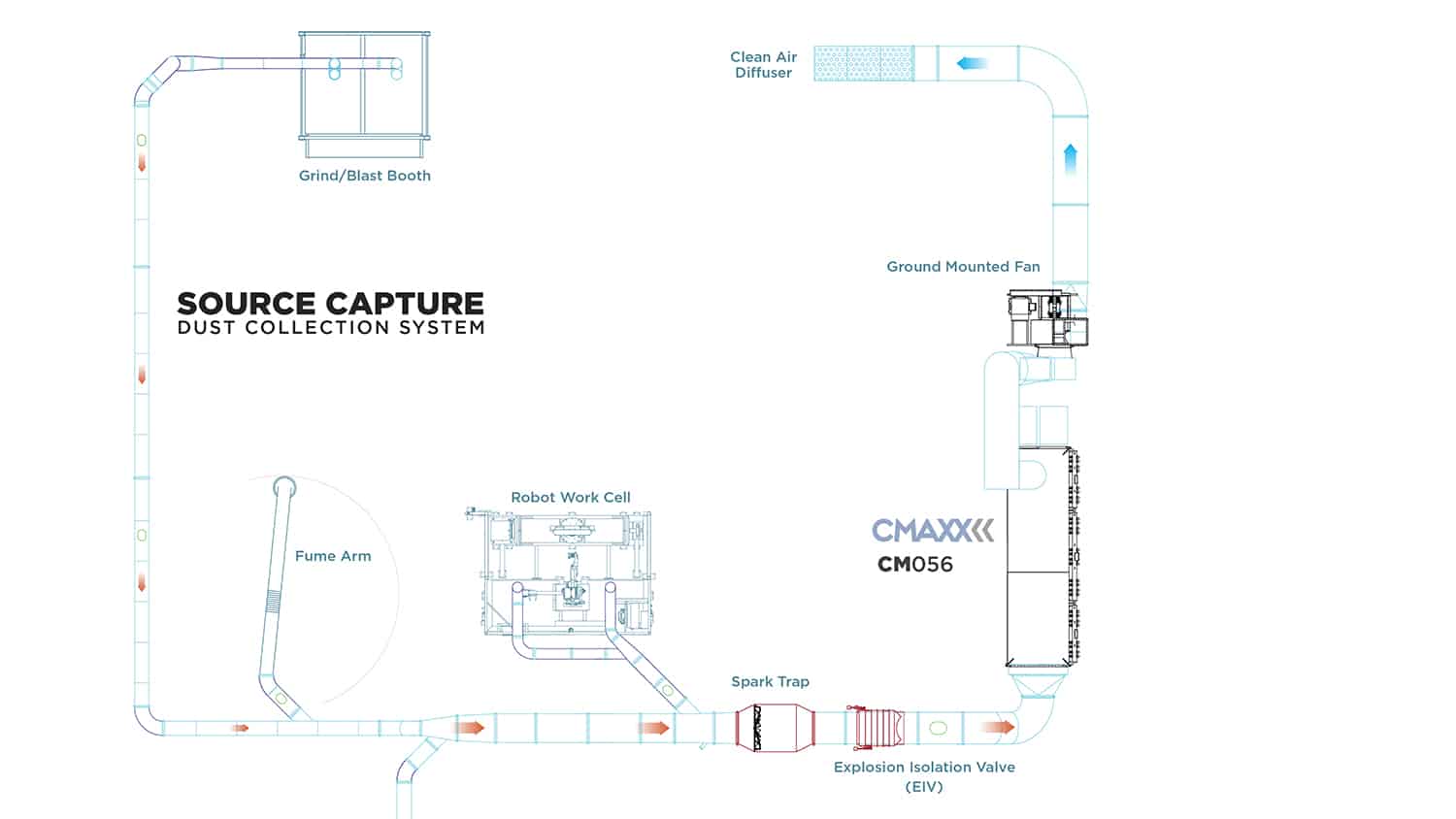

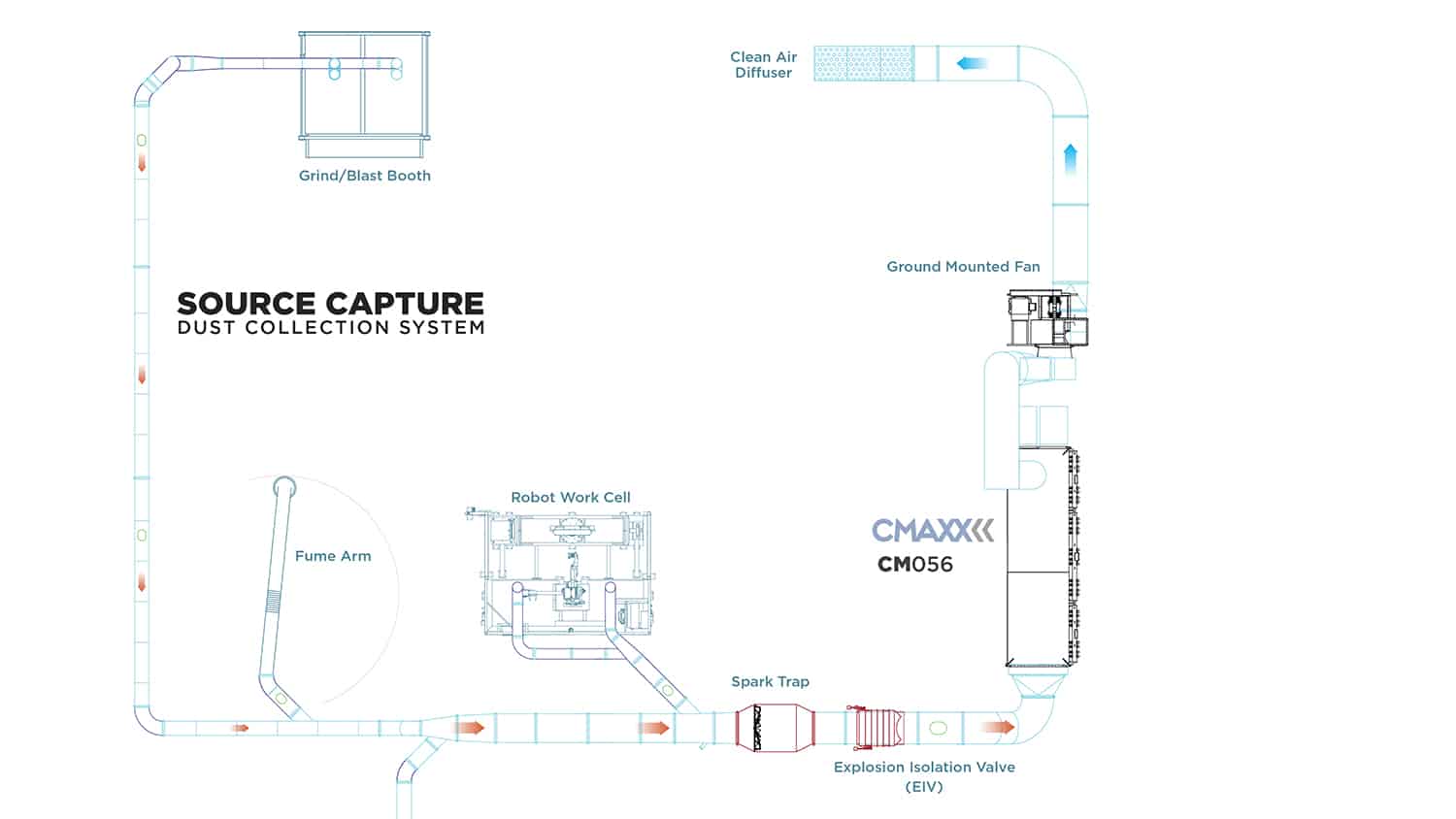

You have several pieces of equipment in your building that generate dust. The equipment doesn’t move around, and most of the dust or fume is generated at a particular point. Examples can be a plasma or laser cutting table, a blast booth, a mixing machine, or many others.

The leanest solution for this situation would usually be source capture. Hoods can be located directly over the equipment, or the equipment can be designed with dust collection built in. An example of this is a downdraft system on a plasma cutting table. These lean solutions for dust collection make sure the dust generated at certain spots doesn’t get out into the rest of the area.

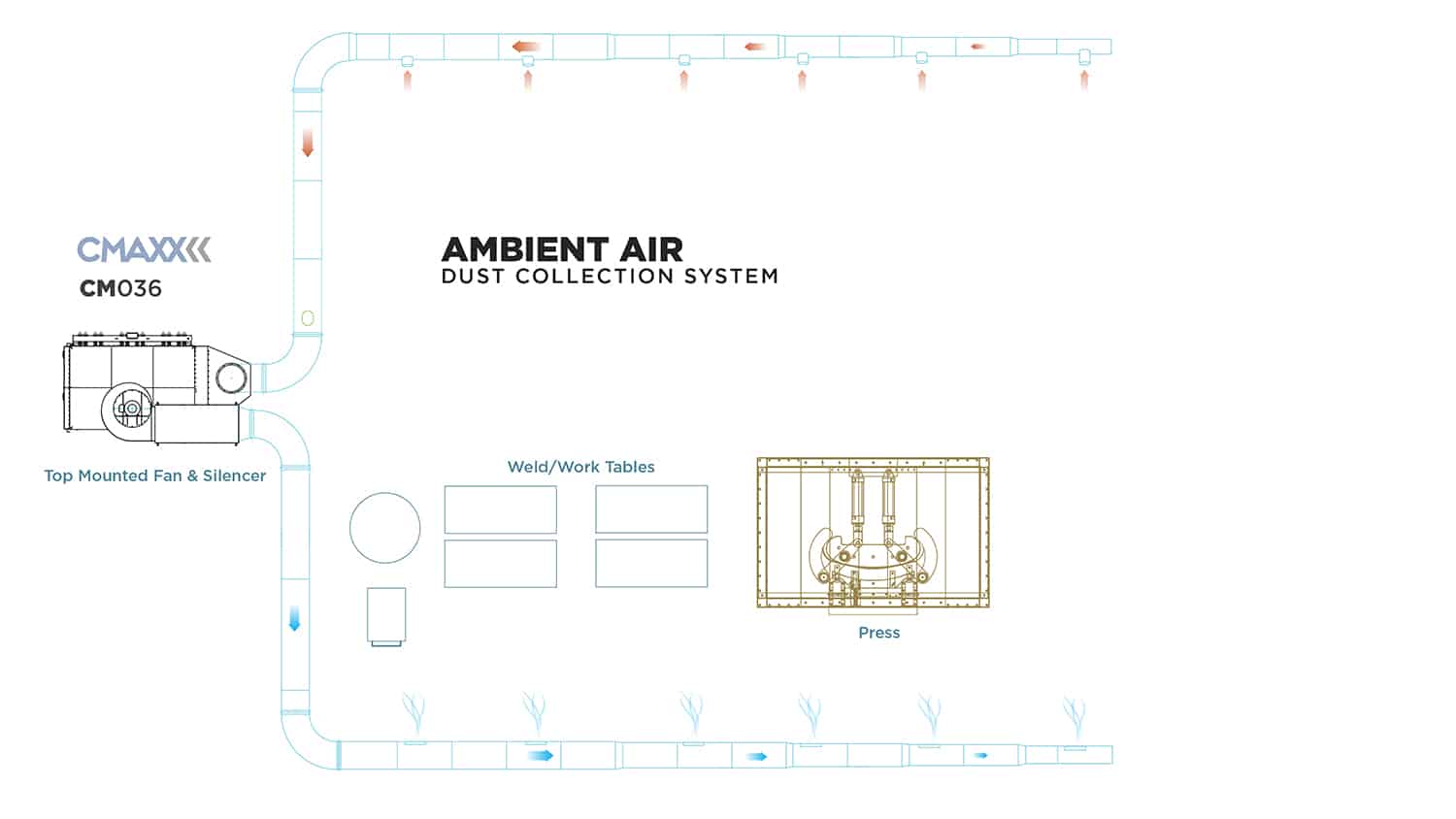

SITUATION 2:

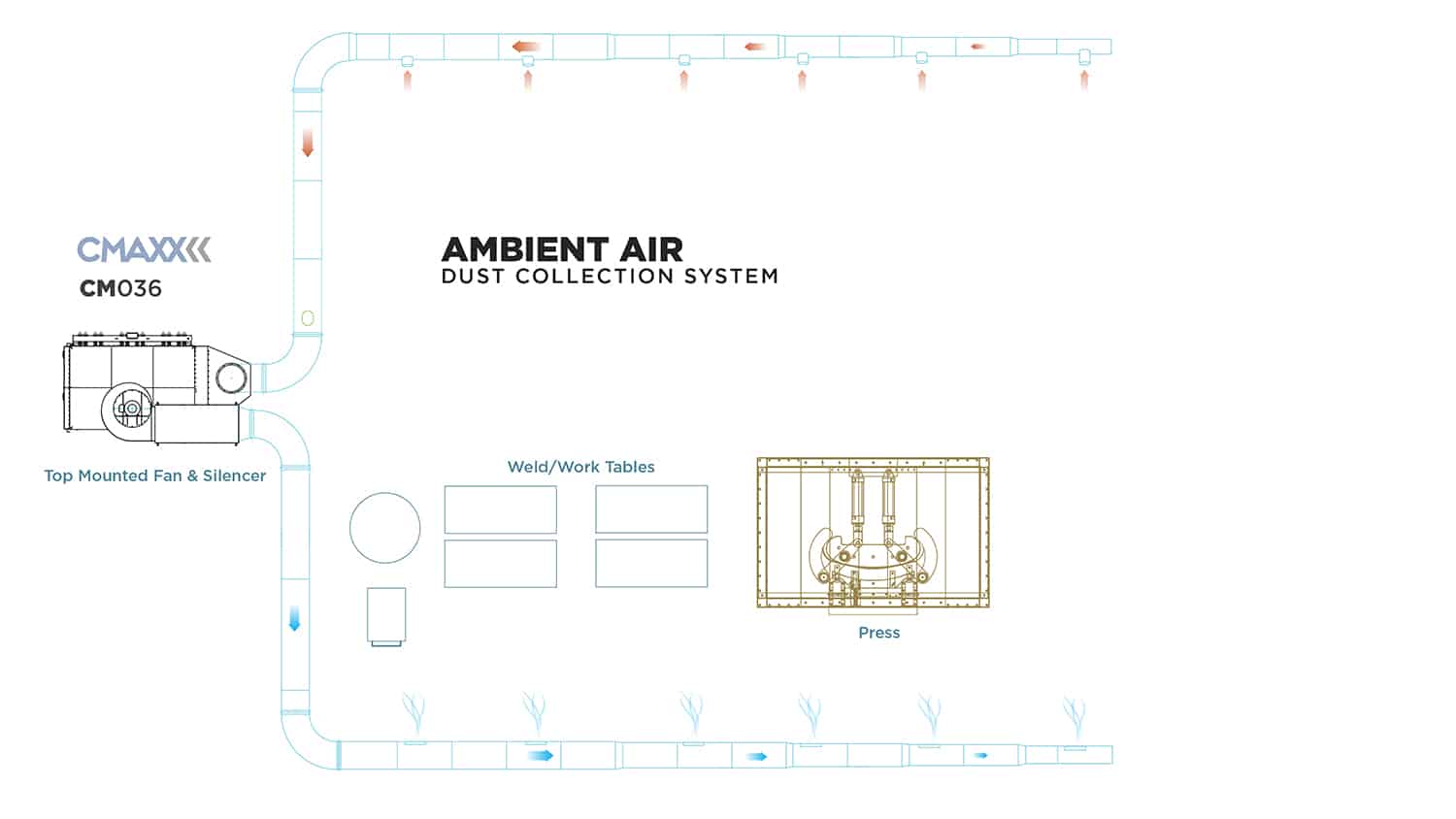

In your facility, welders and fabricators work on assembly of large steel items. The workers usually move around the piece they’re working on. It’s not practical to put hoods over the entire area: the sources of the dust and fumes are moving around, and you would need too many hoods. This would require a huge amount of air flow and huge fans, which is not efficient.

In this situation, the best lean solution for dust collection might be an ambient system. This type of system filters the air in the entire area. It is designed to change over all of the air inside that space within a certain period of time. As it does this, it removes dust and fumes, even if the sources are moving around and can’t be put under a hood. It will keep all the air clean, not just the air around particular machines or work areas.

SITUATION 3:

You have a machine shop with welders and fabricators working on different equipment at different times. Some of the machines might have hoods over them, and the cutting table might have a downdraft system on it. These are examples of source capture.

Another type of source capture often used in these situations is a fume arm. This flexible arm is situated near the welder, and he adjusts it as he works to capture the fumes. He needs to keep the hood of the arm positioned correctly so it’s catching the plume coming from the welding.

While in theory this is an effective method of source capture, it is not a lean solution for dust collection. Time is spent repositioning the hood. Welders deal with the issue of having the hood in the way of the work area, slowing down the process. It is difficult to position the hood correctly for maximum efficiency. These all create wasted time, worker frustration, and inefficient fume collection. The end result: the fume arms don’t get used, and your system is wasting airflow because it’s not collecting anything at those points. Check out the article where Imperial Systems Inc. President Jeremiah Wann tackles this issue directly. Click Here.

In this situation, your system may be able to do double duty as an ambient and source capture system. You can still have the dust collector attached to the cutting table for downdraft fume collection, and hoods over stationary work areas. However, you need a lean solution for dust collection from your welding or similar work areas.

Having ambient dust collection makes sure that the air in the entire facility is clean. It’s often said in lean manufacturing that the best solution is the one people will actually use. Considering that fume arms are often used wrong or not used at all, they’re not the best lean solution.

For each company or workplace, there are lean solutions for dust collection, but they are different for each situation. Contact us to talk to one of our systems specialists and figure out the leanest way to handle your dust collection.

Read more

by Imperial Systems | Jun 22, 2017 | Uncategorized

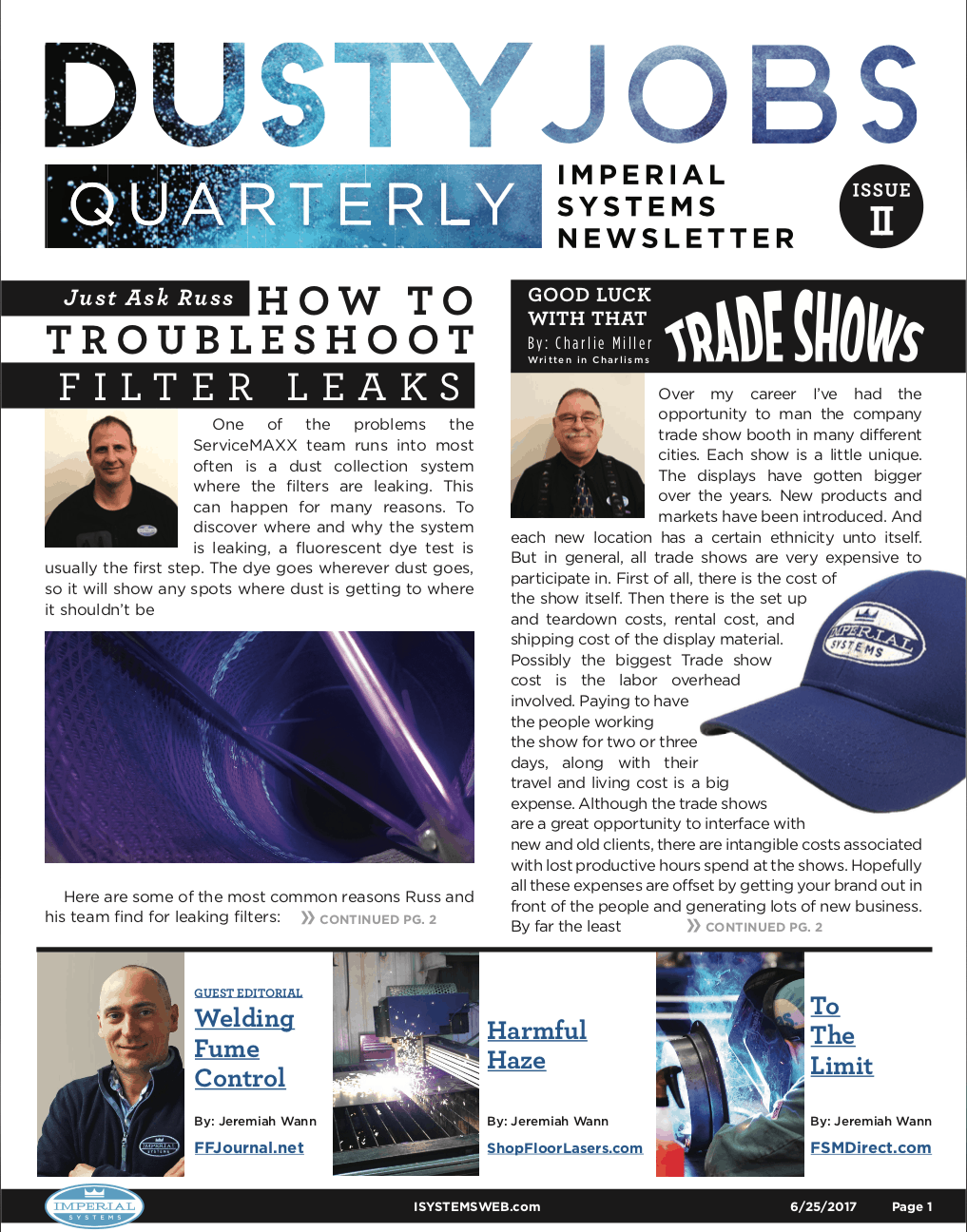

The Second Issue of Dusty Jobs Newsletter. Articles include How to Troubleshoot a defective filter and a story about the different people at Trade Shows and how they score free gear.Dusty Jobs Newsletter Issue 2-1

Download DUSTY JOBS | Issue 2 PDF

Read more

by Imperial Systems | Jun 6, 2017 | Uncategorized

Your dust collector is supposed to keep dust or fumes from getting back into your facility. That means that the last thing you want to see is what we found when our ServiceMAXX technicians went on a service call to this facility: badly leaking filters in their horizontal dust collector.

How do you know you have leaking filters? Obviously, you might see dust in places it shouldn’t be, like coming out clean air vents. You might also see dust in the clean air plenum of the collector, but this isn’t exactly a place that’s easy to get to, especially in a horizontal collector.

The best way to find out if you have dust getting through a leaking filter is to have a professional conduct a dye test. Not only will this show you whether there are holes in your filters, but it will also show you any other places that dust is getting where it shouldn’t be.

DYE TESTING

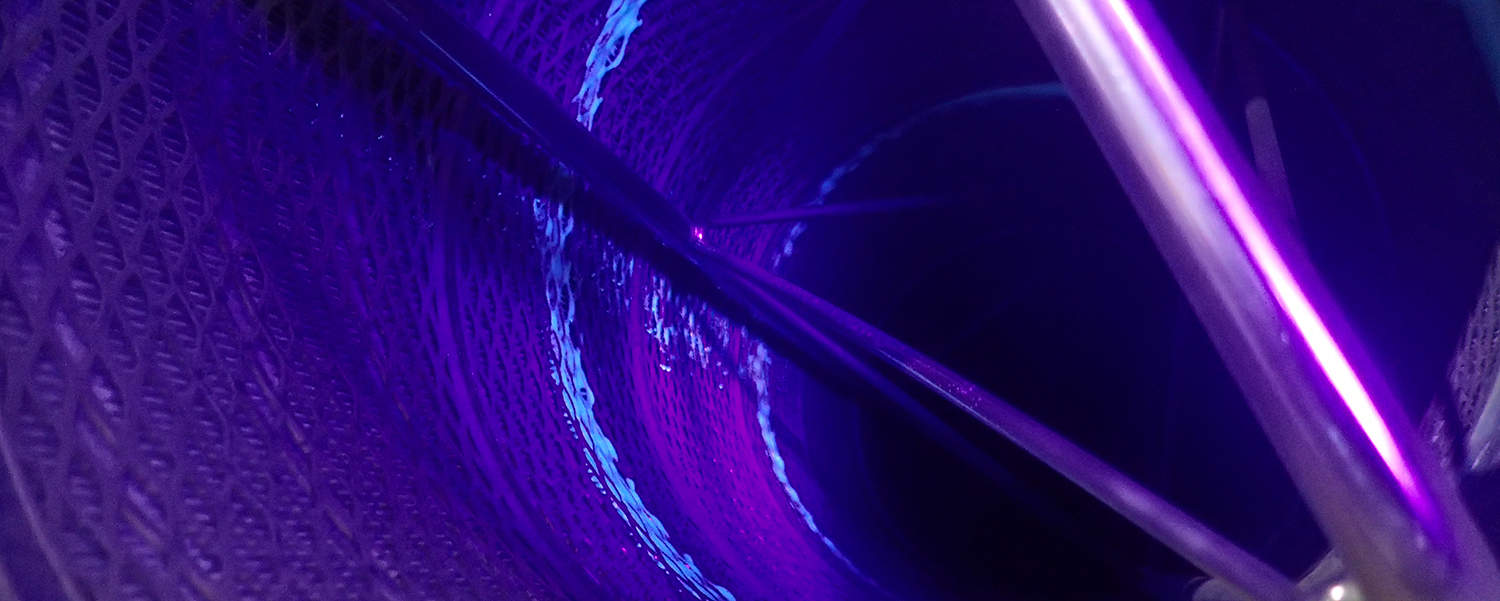

In a dye test, a dye that fluoresces under ultraviolet light is run through the collector just like regular dust. After this has been allowed to go through the collector, everything is inspected with the UV light.

If there are no problems, the dye should only appear on the outside of the filter: the side that is supposed to be in contact with dust.

When spots on the inside of the filter start to light up, you have a problem. Dust isn’t supposed to be on the clean air side of a filter, and if the dye is getting through, dust is too.

WHAT WE FOUND

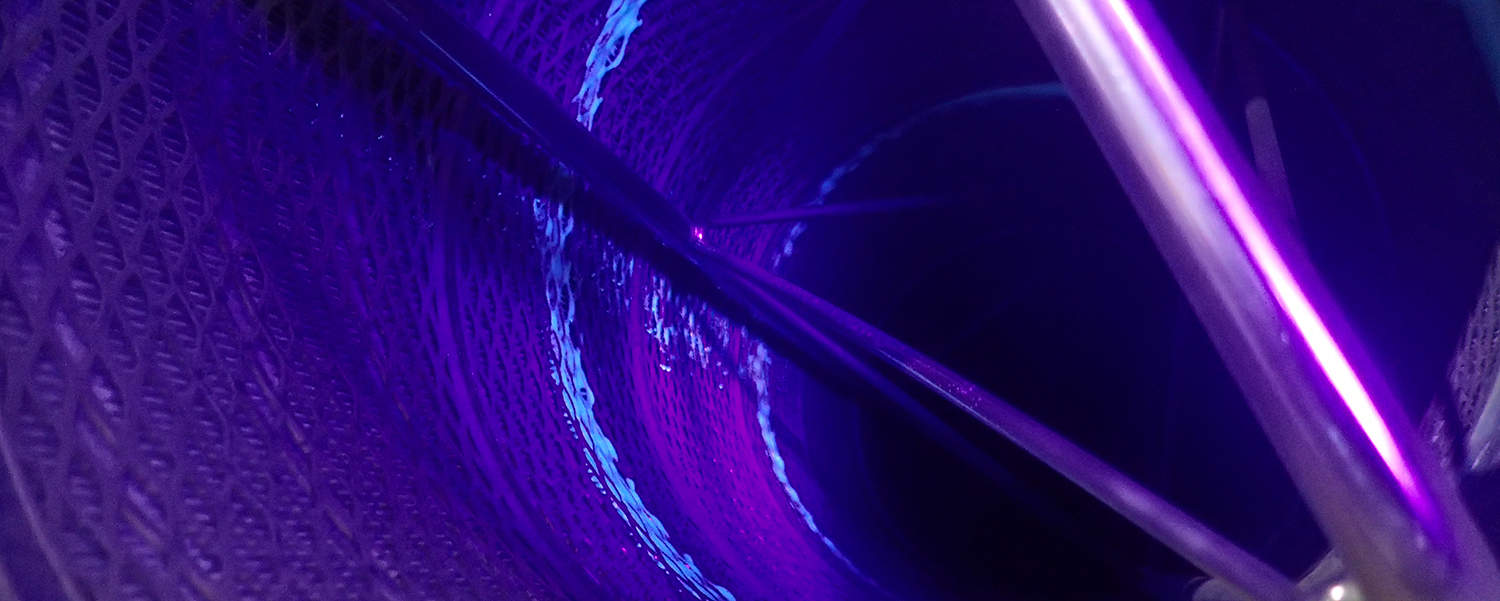

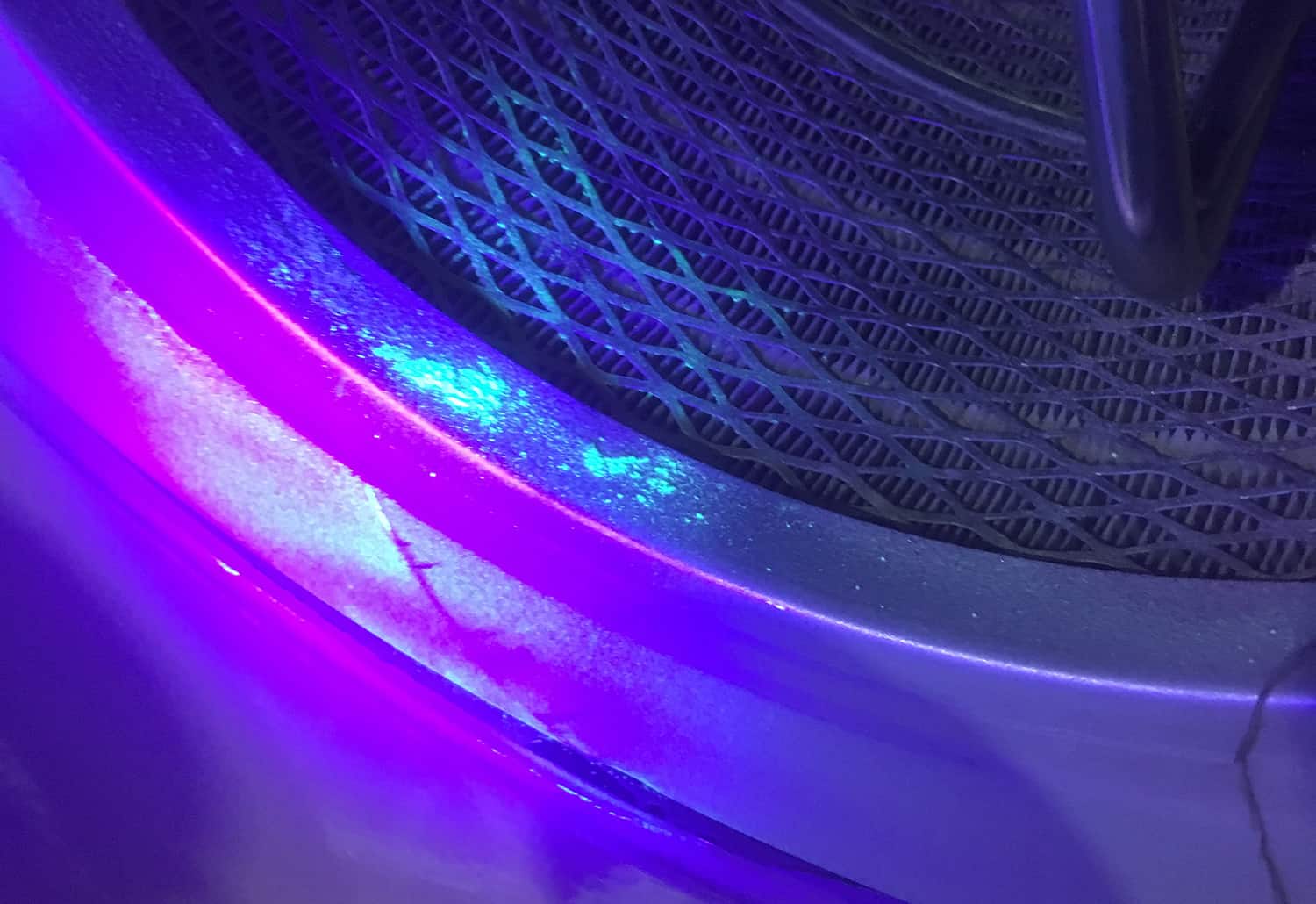

When our service technician visited this company, he found filters that looked like this:

The blue marks show where the dye accumulated after running through the system. This allowed the service technician to discover the locations of several problems. Some of the filters had holes in the filter media, which was probably caused by large particles hitting the filters and damaging them.

Some of them also appeared to be leaking around the gaskets. This is a common problem in horizontal collectors because of the yokes that support the filters, which are easily bent. This can pull the filter away from the tube sheet or the door and cause leaking filters.

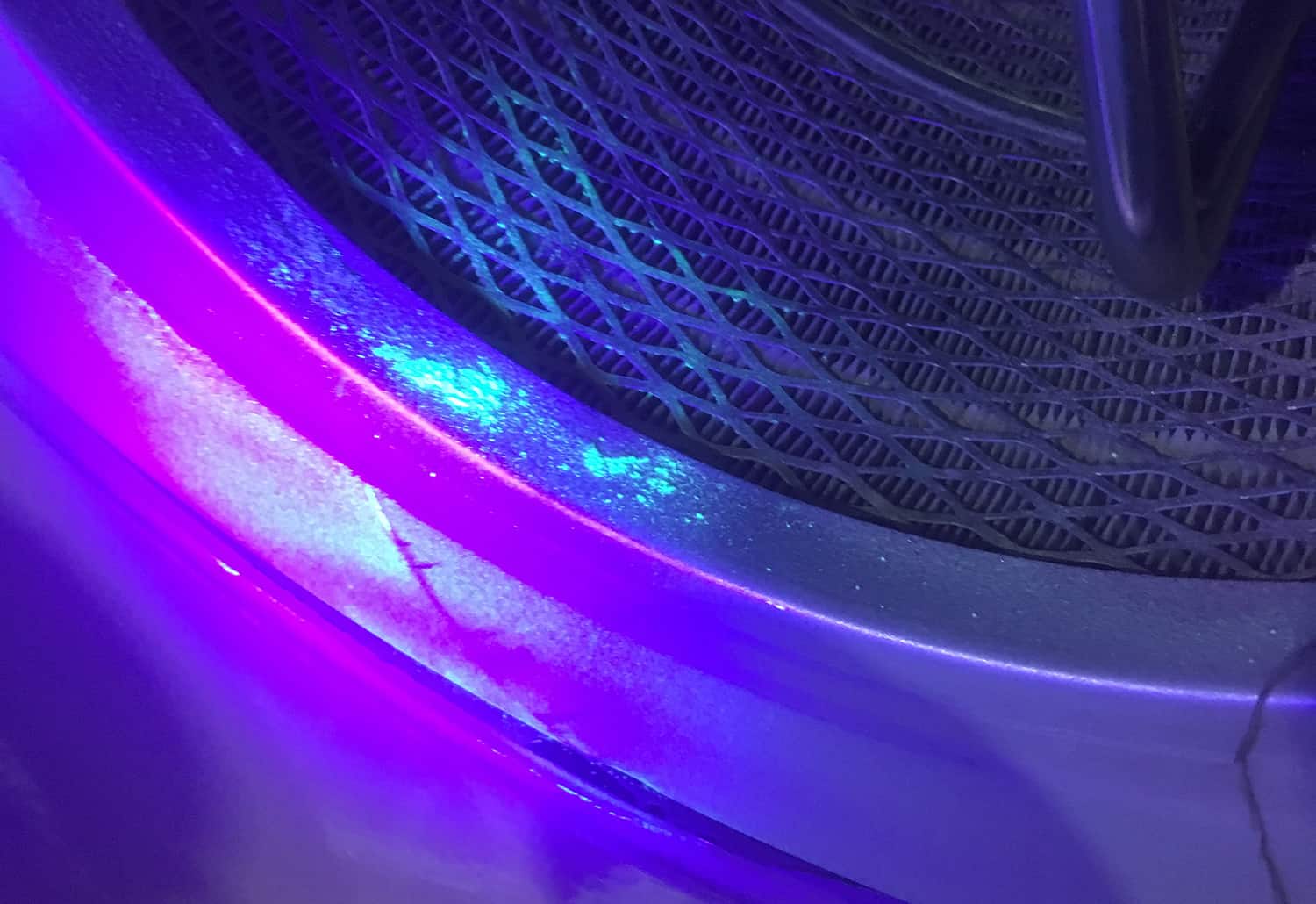

This photo shows how much dust was sitting on the yokes. These are inside the filters and should never have any dust on them unless you have leaking filters.

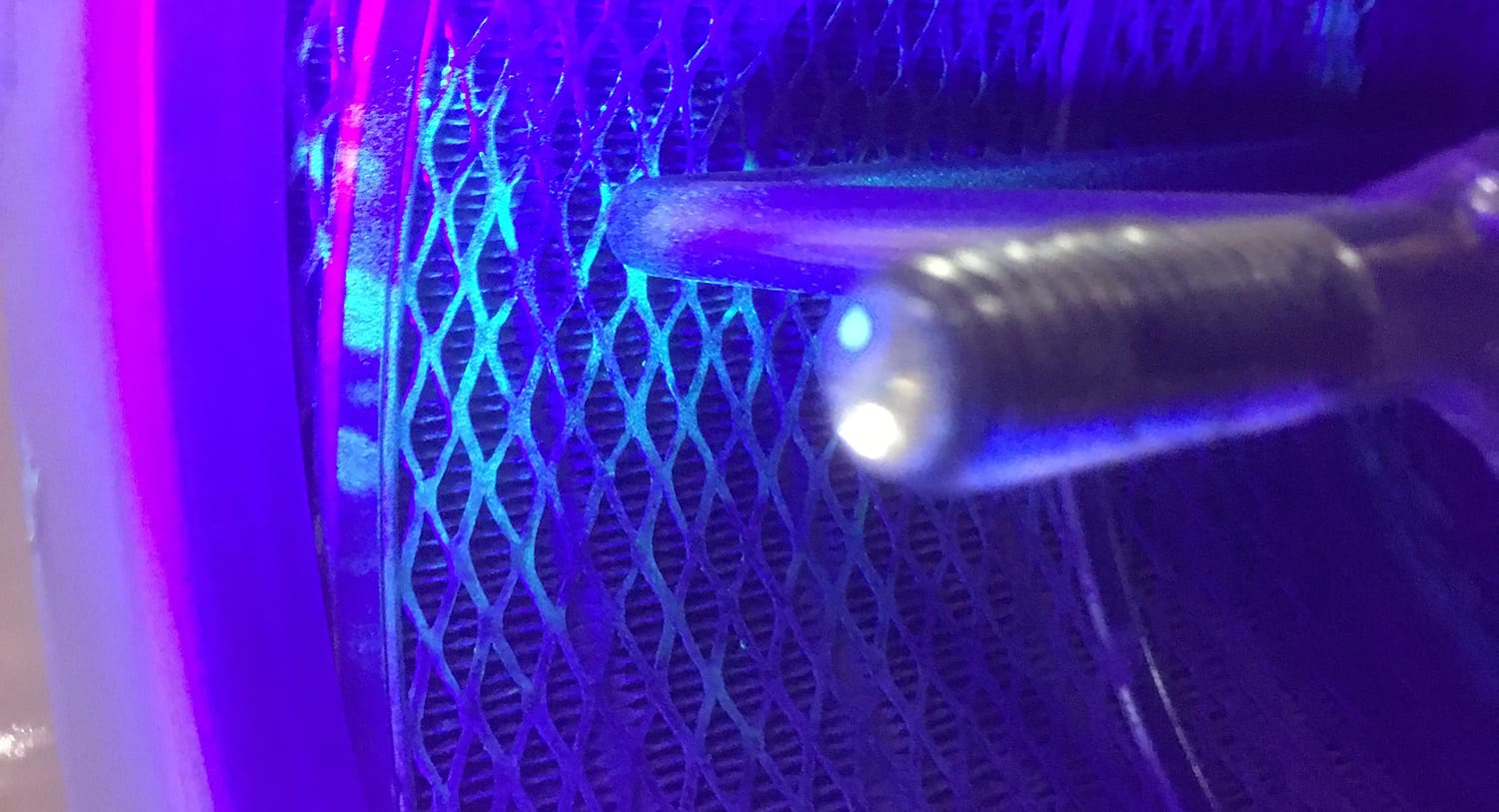

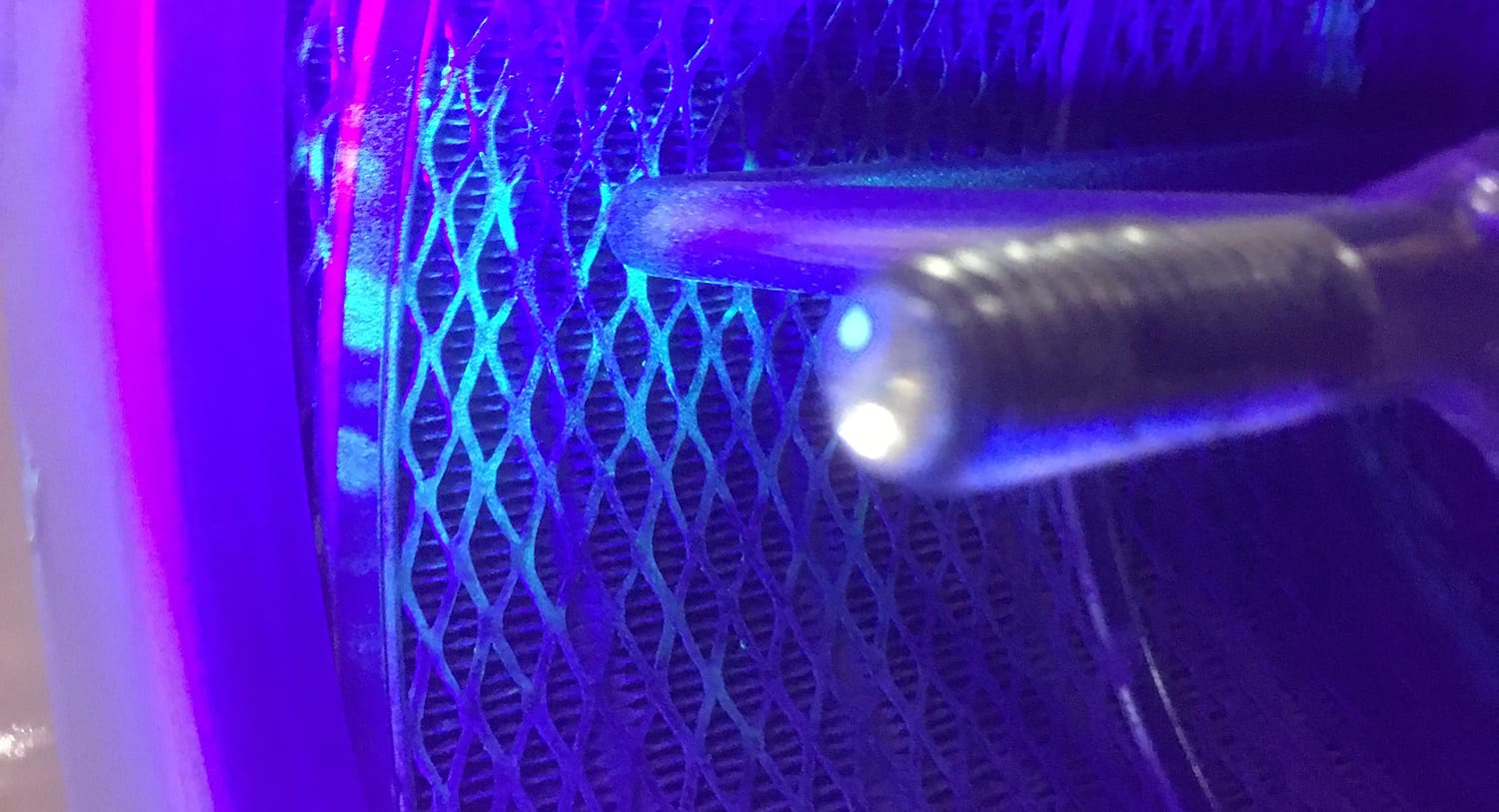

Our technician then took a look inside the clean air plenum to see how much dust had been getting past the filters. The results weren’t good:

This valve in the clean air plenum should have no dust on it or in it. The dye test showed a large amount of dust accumulating inside the clean air plenum. This dust can be very difficult to clean out, even after leaking filters have been replaced. If there is dust in the clean air side of the collector, it will continue to get into your clean air stream even after the filter issue is fixed.

REASONS FOR A DYE TEST

Any system can benefit from inspection by a trained technician. This can find problems you didn’t know were there, or things that can be fixed to prevent a problem.

Some problems that may be identified by a dye test:

- Defective filters with manufacturing flaws

- Failure of gasket seals

- Damage to filters due to large particles hitting them (or being handled incorrectly)

- Filter material damaged by high differential pressure

- A bent or warped tube sheet (usually a problem in horizontal collectors)

- Other areas where dust is getting through

- Dust in the clean air plenum from past leaks that needs to be cleaned up

One frequent cause of filter failure is using the wrong filter media for your dust. DeltaMAXX nanofiber filters are highly recommended over cheaper and less efficient material, and for special applications media like spunbond PTFE can be used. The wrong filter media can cause filters to fail very quickly.

As another good reason to have a technician pay a ServiceMAXX visit to your facility, the inspection and dye test results can be presented in a report to prove that your facility is in compliance and everything is up to standards.

Read more

by Imperial Systems | May 30, 2017 | Uncategorized

To see the article and the rest of Fab Shop Magazine Direct go here: http://magazine.fsmdirect.com/2017/may/d/#page32 or visit their website here: http://www.fsmdirect.com/safety/433-to-the-limit

Read more