by Imperial Systems | Oct 17, 2016 | Uncategorized

As of 2016, the Department of Justice (DOJ) and the Department of Labor (which includes OSHA) partnered to bring federal charges against companies who expose workers to dangerous materials and carcinogens. Hazardous fume and dust exposure in the workplace is indeed a serious offense.

Environmental Protection Laws Facilitate Prosecution

This partnership is to enable prosecutors to use powerful environmental protection laws. With these laws, they can prosecute companies for worker safety violations involving exposure to dangerous substances. This will allow prosecutors working on OSHA worker exposure cases to work with the Environmental Crimes Section of the DOJ to maximize penalties and criminal charges.

In many cases, environmental protection laws are stricter and have stronger punishments than OSHA regulations. Environmental protection has wide public support and considerably more funding than occupational health and safety. There is an entire division of the DOJ that handles environmental crimes. More effectively, these crimes may carry a much heavier fine or more serious criminal charges.

OSHA’s ability to level criminal charges is usually limited to certain situations. This is where an employer willfully and knowingly violates safety standards which cause the death of a worker. These cases can be difficult to prove and even more difficult to prosecute. Under laws regulating environmental crimes, releasing or failing to control any workplace hazard exposure to dangerous substances is a crime. This applies even if the exposure does not result in death or serious injury.

Just like with OSHA fines, the most serious criminal charges will go to employers who repeatedly violate the rules or who fail to correct problems even when they know about them. Bringing in the DOJ and their regulation of environmental laws is likely to affect companies who aren’t following the rules for controlling or cleaning up their hazardous materials.

Identifying Hazardous Fume and Dust in the Workplace

Workplace hazard exposure includes materials such as fumes and dust from many types of industrial processes. Some examples are welding, plasma or laser cutting, manufacturing of plastics and resins, printing inks and pigments, as well as production of chemicals or fertilizers.

OSHA usually sets exposure limits for employees. Environmental regulations set limits for material release into the environment, regardless of the exposure to individual employees. Under the DOJ, environmental laws can handle hazardous material release amounts inside a facility.

For metalworking facilities, hexavalent chromium, manganese, and other components of cutting and welding fumes are heavily regulated as environmental toxins. Exposing people to these materials, inside or outside, can be an environmental crime. Hexavalent chromium often contaminates drinking water, and it’s a major environmental concern.

For companies that use or produce hazardous dust or fumes, a dust collection system is very important for limiting exposure. The system will not only keep the materials away from workers but also collects them safely and allows you to dispose of them properly. A dust and fume collection system that’s maintained and used correctly is a necessary tool for controlling hazardous airborne particles or fumes. Contact us for more information.

References:

www.justice.gov

www.justive.gov

www.justice.gov

Read more

by Imperial Systems | Aug 29, 2016 | Uncategorized

Read these 5 odd metal facts about Tin that you never thought about…and will always remember:

- TIN PEST: At around -20 degrees F, tin will transform itself from a shiny, flexible metal to a dull, brittle powder. This is called “tin pest” and can cause things made of tin to crumble to dust when the weather gets very cold.

- WHISKERS: Pure tin used in electronics is known to grow “whiskers”. These whiskers, which form for unknown reasons, cause havoc in systems where they can act like a tiny antenna, damage delicate parts, or cause short circuits.

- TIN CANS: Tin cans aren’t made of tin. They are made of steel. The steel is sometimes coated with tin to improve corrosion resistance, but cans made out of tin were not only more expensive but also subject to “tin pest”, which made the cans brittle and breakable.

- TIN CRY: There’s a distinctive whining cry that is heard when a piece of tin is bent. This “tin cry” happens because the metal is made up of very tiny crystals, and bending the metal causes the crystals to scrape against each other.

- THE BRONZE AGE: Two thousand years before iron came into common use, bronze was the metal that revolutionized weapons, art, and civilization. This alloy of copper and tin was so superior to any other metal in use at the time that its discovery ushered in the Bronze Age.

http://periodic.lanl.gov/50.shtml

http://www.lenntech.com/periodic/elements/sn.htm

Read more

by Imperial Systems | May 25, 2016 | Uncategorized

Ever wonder how much facilities like yours might be paying when they don’t have proper dust control?

When a facility doesn’t have proper dust control equipment installed, or when they fail to protect their workers from welding fumes or combustible dust, fines from OSHA may be in your future. Since March of 2016, numerous fines OSHA have been handed out for respiratory hazard violations:

- A cement company in Ohio is looking at a $92,000 fine for violations that include silica dust exposure

- A company’s abrasive blasting process without proper air filtration resulted in a $121,000 fine for exposing workers to airborne lead

- Fines for a power equipment manufacturer may total $77,000 for violations including failure to evaluate dust hazards

- A pallet manufacturer is facing $152,000 in fines for safety hazards including combustible dust build-up

- Exposing workers to lead and cadmium dust at seven times the permissible limit will cost a Pennsylvania foundry $42,000

- A minerals company that failed to provide proper air quality and dust control exposed workers to lead and arsenic, which may cost them $106,000

Is your dust collection system ensuring you don’t face these kinds of fines? Imperial Systems can help! Our custom-designed dust control systems will help keep your facility and your employees safe. Call one of our knowledgeable team members today to learn more! 800-918-3013.

Read more

by Imperial Systems | Oct 7, 2014 | Uncategorized

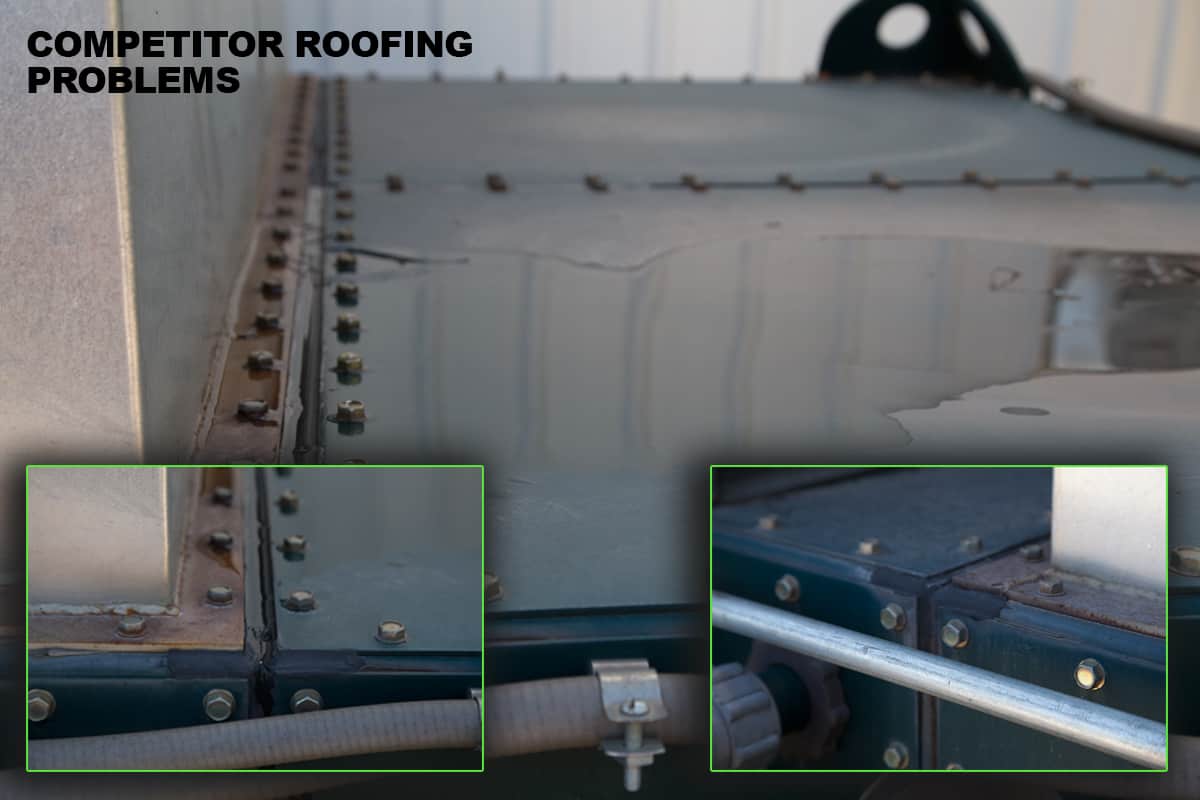

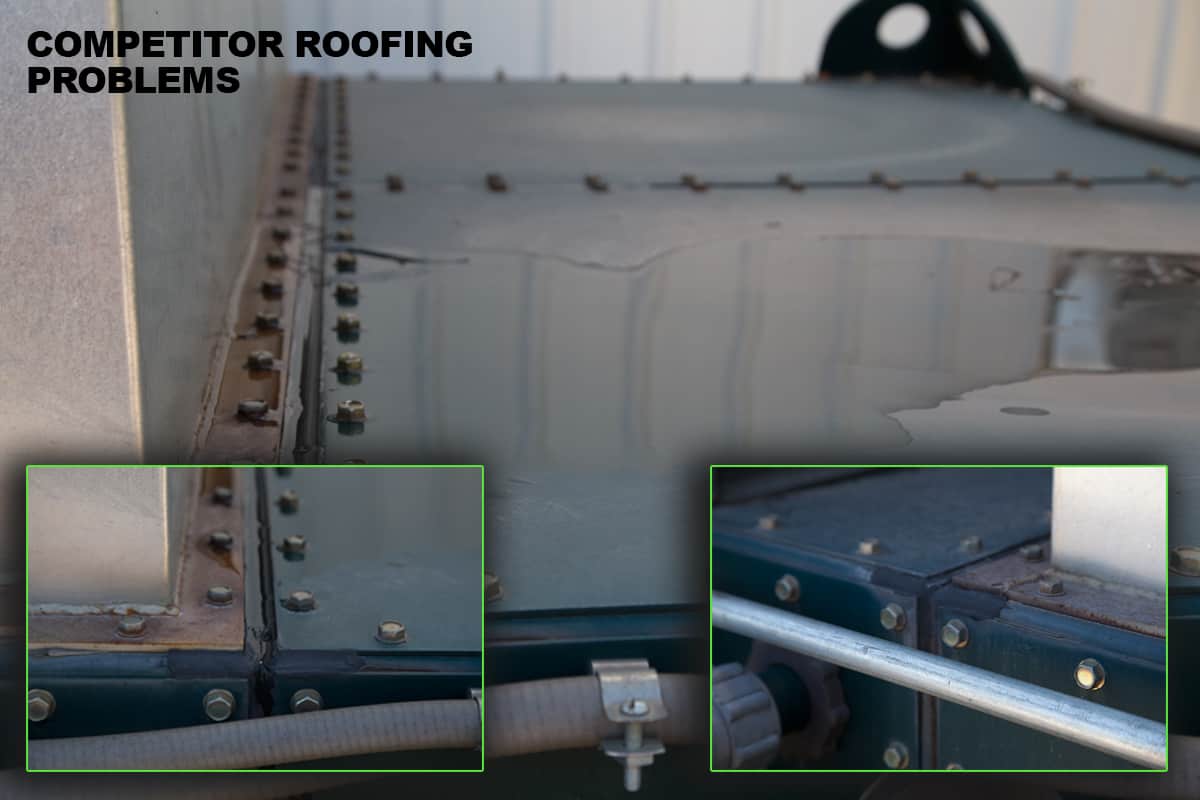

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.

The three key features of the new roof design are: 1. Zero bolt holes, 2. No individual panels, and 3. No roof seams between the modular.

Imperial System’s competitor’s similar unit, with 16 cartridges, has close to 68 feet of sealed connection and approximately 160 bolt holes with over 1000 holes throughout the collector from the bolted panel design. This old style of fabrication leads to potential leaks and holding water resulting in rust and damaged equipment from freezing.

The CMAXX Dust Collector stands tall on the claim of no external bolt holes with an industry best 15 year warranty.

The new CrownTECHTM roof is set to display this year at Fabtech 2016 in Las Vegas. Be sure to stop by booth # N1825 to check out Imperial’s products.

These pictures show how the competitors roof holds water from the panels being under vacuum. It also shows corrosion around the external bolts and bolt holes

Read more

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.

Imperial Systems has changed the roof design of all CMAXX Cartridge Dust Collectors to have a solid one-piece roof. The CrownTECHTM roof on the CMAXX is fully reinforced and slightly positively bowed to make the unit stronger and assist with water runoff. Even with these changes, the CMAXX dust collection system still holds the title for the only modular dust collector with no external bolt holes.