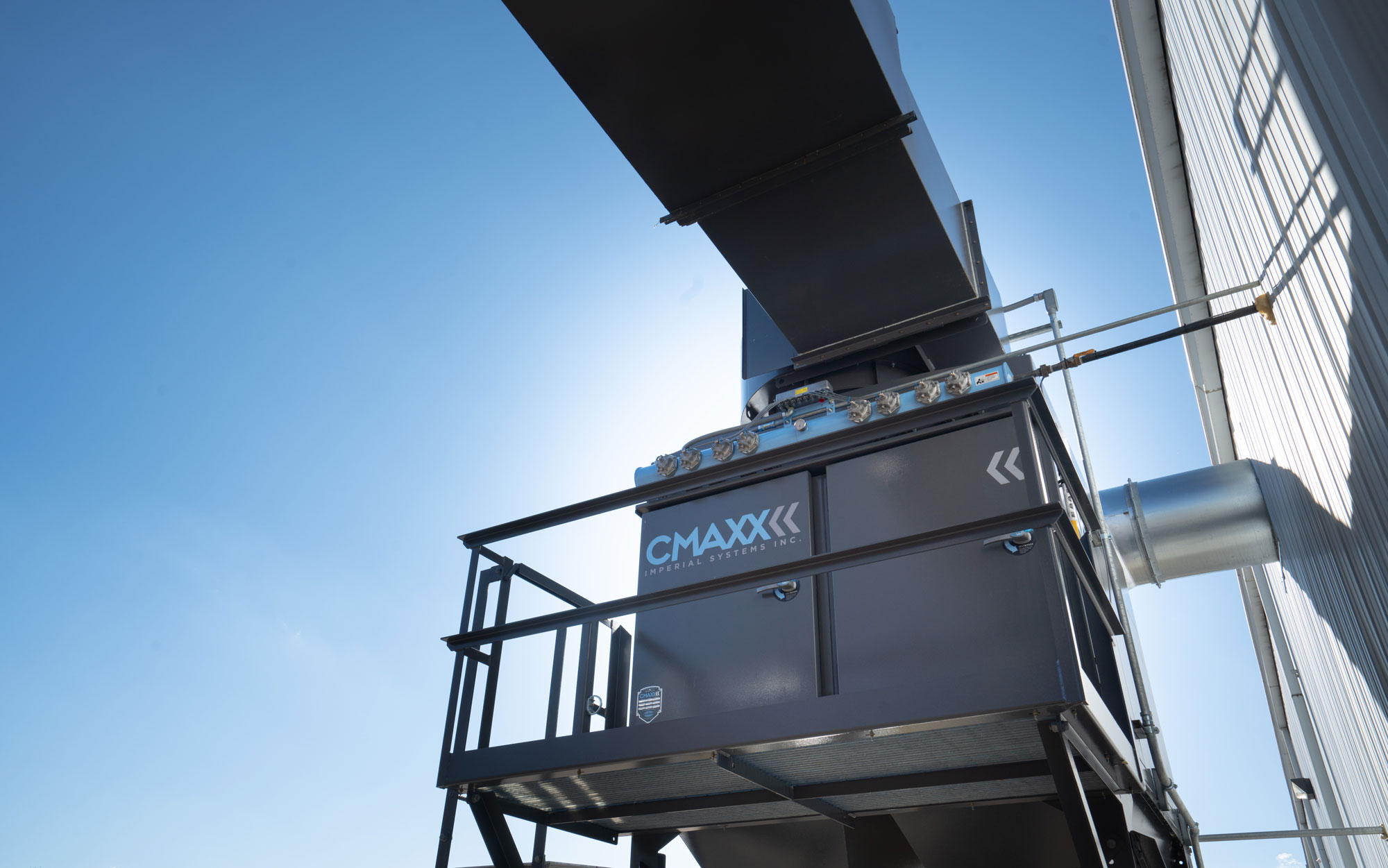

Tomm Frungillo from Imperial Systems joins us from his home to talk about innovation. Tomm talks about our flagship product the CMAXX Dust and Fume Collector and how it is always in a state of improvement. Donovan and Tomm also speak on the culture of Imperial Systems and how it revolves around safety and efficiency for the customer.

To learn more about the products in this episode visit our products page. https://www.isystemsweb.com/dust-collection-equipment/

Dusty Jobs Podcast Episode 5 – Innovation with Tomm Frungillo

Narrator: Welcome to the Dusty Jobs Podcast from Imperial Systems. Industry knowledge to make your job easier and safer.

Donovan: Hello, and welcome to another Dusty Jobs Podcast. We’re still here in our homes filming today because of the coronavirus. On today we have Tomm. Tomm, how are you doing?

Tomm: I’m doing well, Donovan. I hope you are, and I’m glad to be here with you.

Donovan: Yeah, glad to be here with you too. Tomm, where are you sitting right now?

Tomm: I’m in North Carolina, my home office. As you know, I’m up there about a week a month, normally, and traveling all over the country other times, but like everybody else we’re at home and getting things done.

Donovan: Yeah, so Tomm’s here to join us today. Tomm, tell us a little bit about your role with Imperial Systems.

Tomm: Thank you. I’ve been with Imperial close to two years now as director of sales and marketing. I’m really trying to, along with that, spearhead innovation with the company and coming up with new and better ideas to serve our markets.

Donovan: Yeah, and that’s what we’re going to be talking about today. Innovation; some of the ones we’ve done in the past but mostly the ones we’ve done real recently. Let’s start out with where our innovations started in the past, Tomm. You’ve been in the industry, like you said, for a long time. What some things that you notice that have been pretty innovative about Imperial Systems in the past.

Tomm: Well I think when you look at the history of the company it started with innovation and creating a rep firm that turned into a systems organization that turned into an equipment manufacturer and I think its always kind of reinventing itself. About ten years ago the flagship product, the CMAXX, was created and there were a lot of innovative things. It wasn’t the first cartridge dust collector in the history of the marketplace, but it was an innovative collector with things that were designed into it. I came on to kind of continue to spearhead the culture of innovation and creating new and better equipment and new and better things for the marketplace.

Donovan: I know as I came on with Imperial one of the things that I appreciated was that how the stories I was told from the past on how the innovation was done really for the benefit of the end user. One of the things I always loved to hear is that ours has a domed roof and that came from one of our end users down in Florida who was always having rain water sit on top of their machine and said, “Hey, is there a way you guys can help me out with this?” And we came up with the domed roof. Theres a lot of different features like that that are already integrated into the machine. Just in the last year we came out with a couple new ones that I think are just great and I was hoping you could unpack those for me today Tomm.

Tomm: Yeah, well there are several. Every manufacturer of equipment or otherwise is looking, especially in this day of lean manufacturing, is trying to do things better, more efficiently. So, I think anything a manufacturer can do to help benefit the manufacturer is great. But ultimately, what we try to do, is figure out what we can do, what we can come up with that’s new, that’s benefiting the end user. Thats the important thing. So that’s the way we approached it for many years now, and certainly the past two years since I’ve been here where we’ve come up with improvements to our flagship CMAXX product, specifically the Safety Pentagon, that are five safety items that improve the end users position. That maintenance worker that has to change cartridges. Instead of looking at just how it benefits us, its always looking at how it benefits that customer.

Donovan: What are the five things that were changed out recently that make it a better and safer product for our end user.

Tomm: Sure. The main ones I think are the anti-ramp lift rails. So if you’re installing a cartridge it goes in and one goes behind it. In the past, even on our old ones and everything that’s out here in the marketplace now, you have the opportunity to ramp one cartridge pan onto the other in traditional designs. We’ve eliminated that. It’s very important so the customer is not ramping which can release dust and toxins into the air if its not seated properly. Another one is the fact that in previous units you could close the door and not have the cartridges seated properly. In one of the Safety Pentagon items we eliminate that from happening. Those are the kinds of things we look at to make sure that from an end user, from a maintenance guy’s standpoint you make it as easy and as safe as possible for them.

Donovan: Yeah, I’d say that is one of my favorite features. Theres three different ways, that if its not in there right, its going to keep that door from closing. What a better way to know if somethings not right, if the door doesn’t close? If you can’t get the door closed, you know somethings not going right.

Tomm: That’s right.

Donovan: It’s just exciting to see stuff like that, and I happen to be there during one of our brainstorming sessions internally. We were just looking at the machine and coming up with the door stop on the lift rail. It’s just great to see that at our company its not just a bunch of engineers sitting a room thinking about it. We were having a meeting with our service techs, with our sales department, and all the guys from engineering and that’s where that idea came from. I’m glad to know that you’re here to continue that on. I know you have a couple strategies for that too, right Tomm?

Tomm: Well, yeah. We’ve created a culture of innovation. So, this is not only basically sitting our whole group, not only our engineering group, our sales and marketing group, our service group, we sit down as you know, once a quarter and analyze where we are with certain things, what’s really good, what can be improved on, and then come up with improvements on existing equipment. In addition to that, what’s new? What haven’t we thought of yet? What’s going to be the CMAXX of five years from now? Ten years from now? So, its really creating a culture of innovation. That’s important. As you know, we meet on that quarterly. In addition to that, we are always asking our customers how we can make things better. Customers come up with great ideas and we try to implement those ideas.

Donovan: I’m looking over your shoulder there and I see the Shadow hanging up there. That’s one of those ideas that came from a request from one of our customers, if I remember correctly. Isn’t that right?

Tomm: Absolutely. A customer that we’ve done some work with and wanted to do more work with. We said, “Hey, where are we lacking? What would you like that we’re not providing?” They said, “We would like a small footprint, short profile, price point focused unit on particular cutting tables that we have. We don’t want this thing to be a monstrosity. We want the focus to be on our product. We want your product to be in the background, kind of in the shadows.” And so we came up with the product called the Shadow, which doesn’t overtake the money making product of the customer, which is the cutting table, but it’s a plug play, meaning that they can bring this thing right in, run power and air to it, ductwork, and it’s ready to go.

Donovan: Nice

Tomm: Yeah. It’s a short profile, it sits in the background. Turn the switch on and it runs. It does it’s job and its at a price point that they can swallow.

Donovan: Now through the innovation of building that machine I know that we designed it for that application, but we’ve found a bunch of different uses for it. It can handle weld smoke. It can handle a lot of different things. Where that product started and where it might end up are totally different spots.

Tomm: Well that’s very true. We are going to limit it in footprint because originally we wanted to keep it size limited. So, like on the CMAXX where we can go to one hundred and twenty cartridges or more, this is going to be limited to a six cartridge unit. There is a six, a two, and a four cartridge unit.

Donovan: Now, are there any other limitations on it?

Tomm: Well, there is. Part of it being a price point unit is that we’re not building it like we do the CMAXX, which is very heavy duty. So, it’s not able to handle combustible dust. That’s one of the limitations. It’s not meant to do that.

Donovan: I know that we have a lot of customers that deal with combustible dust. Speaking of that, we had a customer come to us not too long ago and talk to us about how they are having issues with their rotary airlock valves on their combustible dust.

Tomm: More often than not we’re dealing with combustible dust and the CMAXX does a great job with that. The BRF, another product, does a good job with that. One of our biggest clientele is in the blasting industry and they’re dealing with potentially combustible dust. Traditionally they’ve always had to put cast rotary airlocks, NFPA compliant, expensive, rotary airlocks on the bottom of their dust collectors. So, customers came to us and said, “Hey, are there some options here other than that?” So, again, back to the innovation drawing board came the Rhino Drum. That is a drum set up kit that is able to handle an ST-1 combustible dust, and do it safely, and meet NFPA compliance.

Donovan: I’ll tell you what, Tomm. Personally, since I’ve had the opportunity to demo that, and use it in the field, some of the features on it that I love, that we didn’t even have to do but we did anyways; the way the lid slides out of place and makes it easy to slide the drum out. That personally is my favorite feature on it. It just makes it so much easier than trying to monkey with some chains or other stuff. That’s what I’ve enjoyed about the Rhino Drum. Not to take away from the safety of that product as much as the safety of the person that’s using it, that they’re not dealing with that airlock. They’re also safe from any explosion. I mean, I’ve seen the videos. We blew that thing up.

Tomm: Yeah, of course it’s always fun to test those things for combustibility and explosion protection. I think as you know we’ve sold some Rhino Drums to not explosive applications too just because of the ease of that twist lock. People like that better than the traditional drum cover kit. Aside from that, it’s substantially cheaper than and NFPA compliant airlock. It’s very safe and addresses that ST-1 dust. So it’s a really nice product. Simple, but innovative and nice.

Donovan: One of the product I like too is when we’re talking about the hopper, and where things build up, is our Dust Level Sensor. That to me is really great. I know I’ve talked to some customers in the past, and Tomm, I’m sure you’ve seen this too, where the problem they have with their dust collector is that unfortunately no one is checking to see if they’re cleaning out the hopper. Man, that causes some issues.

Tomm: Well, it can. You know, you build up material in your drum, which if not checked can go into your hopper which can then go into your cartridge area. I have, and you probably have Donovan, most people who have been in the industry a while, cleaning out a dust collector manually is no fun. So, ideally you want to know what level of dust is in your drum, is in your collection device, and that’s what the Dust Level Sensor does. It does it at a price point that’s attractive. There have been other options out there on the marketplace. The good ones are expensive, and the bad ones don’t work very well. We’ve come up with a good combination that works well and is not very expensive. Again, we were looking at what the end user asks for and needs.

Donovan: Yeah, and one of my favorite features on that one is that it has an output so that it can do anything. Once that bin hits a certain level, it can turn your machine off, it can send a horn out, it can put a light out, whatever you wire it to. It’s just to make sure that its a safe and clean environment for whoever going out there, that its not building up. Ultimately, it’s saving your machine and saving downtime.

Tomm: Exactly. Again, the benefit of the customer. What are they looking for? What do they need improvements on? That’s the culture we’re trying to build here, the culture of innovation, the culture of continuous improvement. I think that we’ve done that, but like always, it can always be better. It can always be improved upon. So, that’s what we strive to do on a daily basis.

Donovan: Exactly. If you’re listening to this out there and you have some questions or you have some issues that you’d like us to help you solve, feel free to contact us. Write in. We’re always innovating. We’re always trying to make things a safer and healthier environment for you out there working, and working on dust collectors. If there is a way we can help do that for you, we’re glad to come up with that next product, that next solution for whatever going on. Tomm, anything else you want to say about this?

Tomm: I appreciate the time. I think we’re going to do more of these. I think, hopefully, that they’re informative for folks in the industry about technology and innovation, and of course about our products and how we think they’re the best in the industry. So I’ve loved doing this, and I’d be glad to do it again Donovan. I appreciate the time.

Donovan: Yeah, thanks for coming on Tomm, and thanks for listening.

Tomm: Thank you.

Narrator: Thanks for listening to the Dusty Jobs Podcast. Breathe better, work safer.

.

.